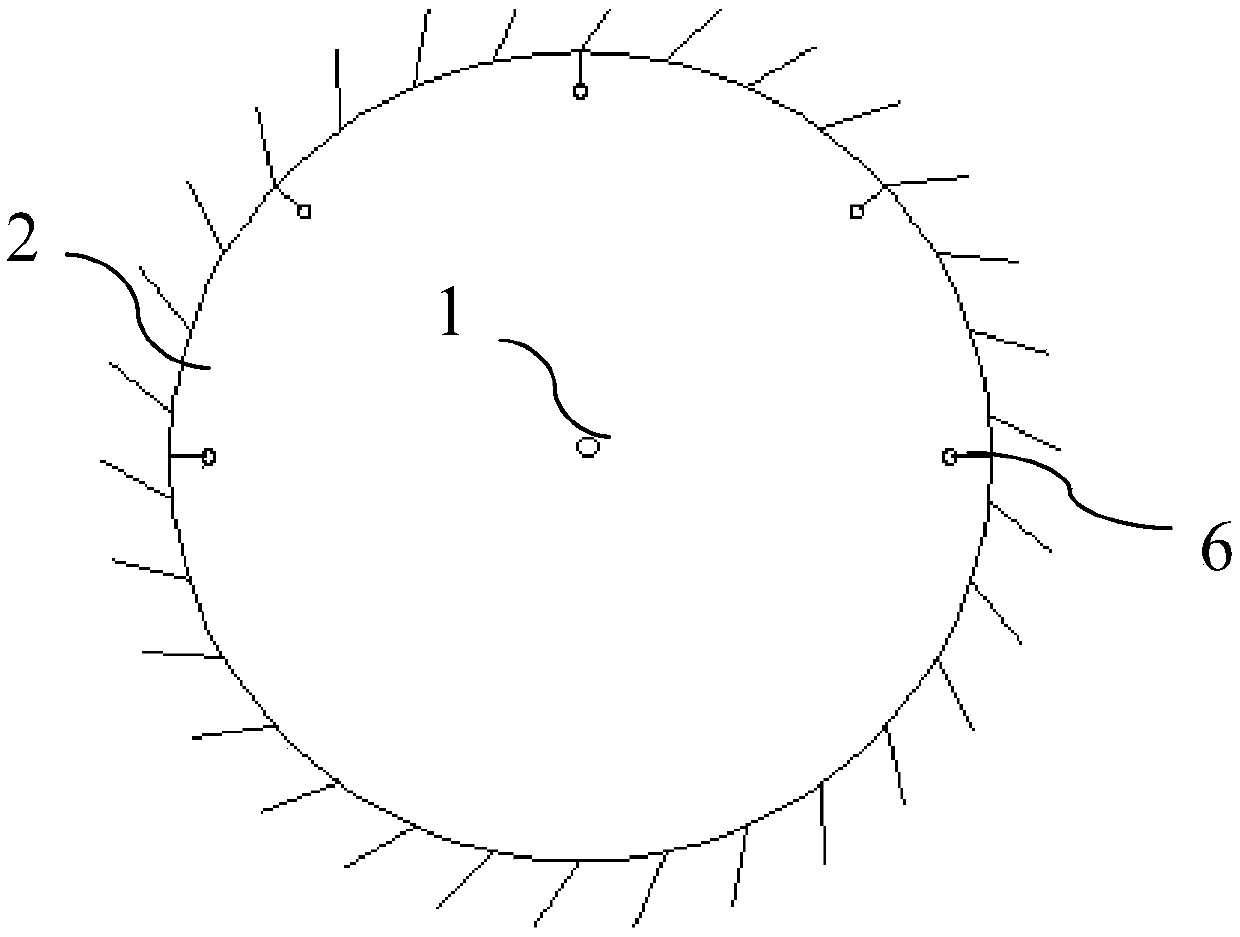

Round small-section tunnel excavation profile control construction method

A construction method and contour control technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of small working space, slow excavation speed, and difficulty in controlling the tunnel excavation contour.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] According to one embodiment of the present invention, the cut blast hole 5 adopts a V-shaped slanted cut to form a larger free surface after blasting, and the free face is formed by the air and air generated by the soil during the blasting process. The contact surface and the air surface play an important role in the blasting, and the blasted soil needs to be moved and destroyed along the air surface to ensure the blasting effect.

[0045] According to one embodiment of the present invention, in the process of drilling, it is required that the drilling depth exceeds the design depth by no more than 20 centimeters, the movement range of the orifice is no more than 2 times the aperture, and the drilling angle deviation is no more than 1 degree, so as to ensure Subsequent explosion effects.

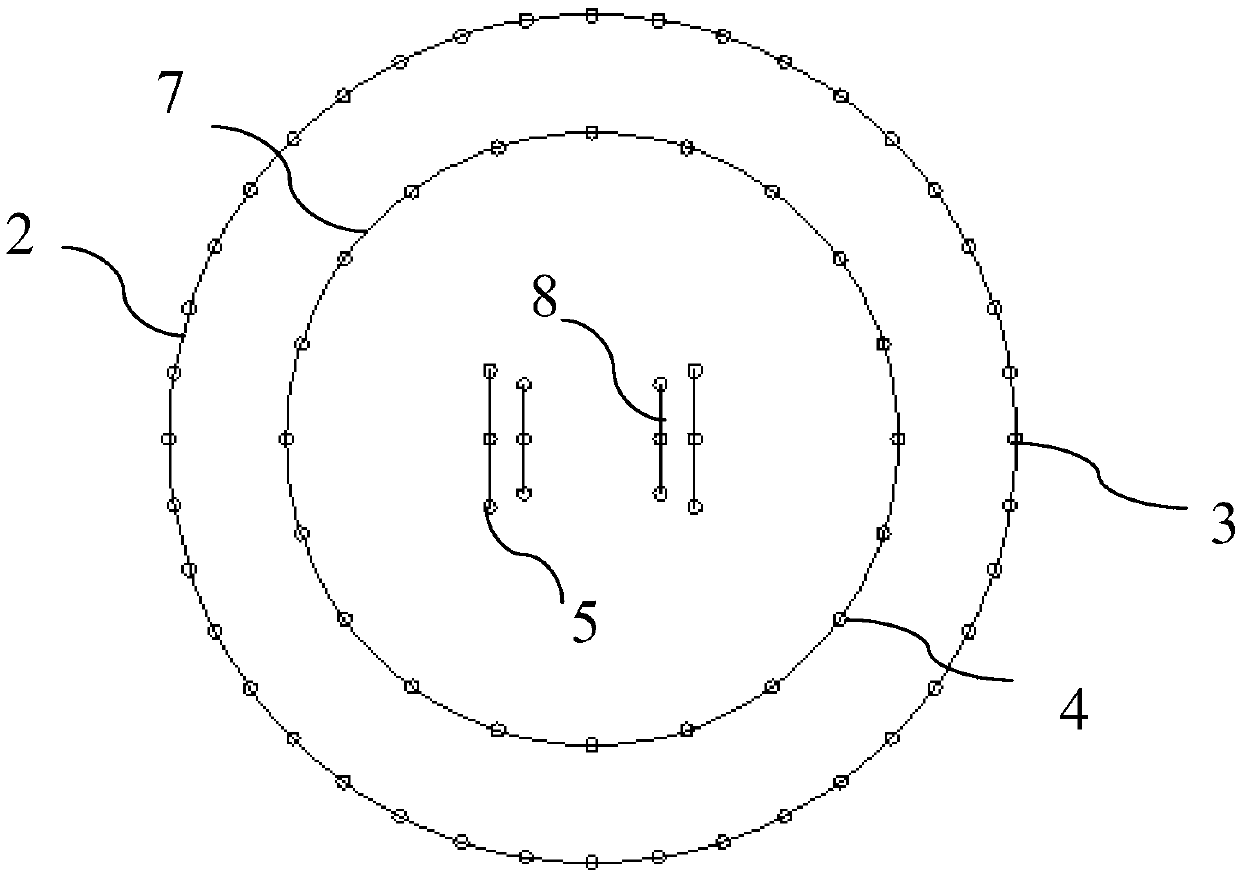

[0046] According to the technical solution of the present invention, step: S3) loading photoblast rolls into the formed blast holes 3, the auxiliary blast holes 4 and the cut blast ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com