Excavation method of underground spherical crown type dome

A technology of spherical crown and spherical crown, which is applied in the field of excavation of underground spherical crown domes, and can solve problems such as irregular contour surface, low excavation precision, and poor molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

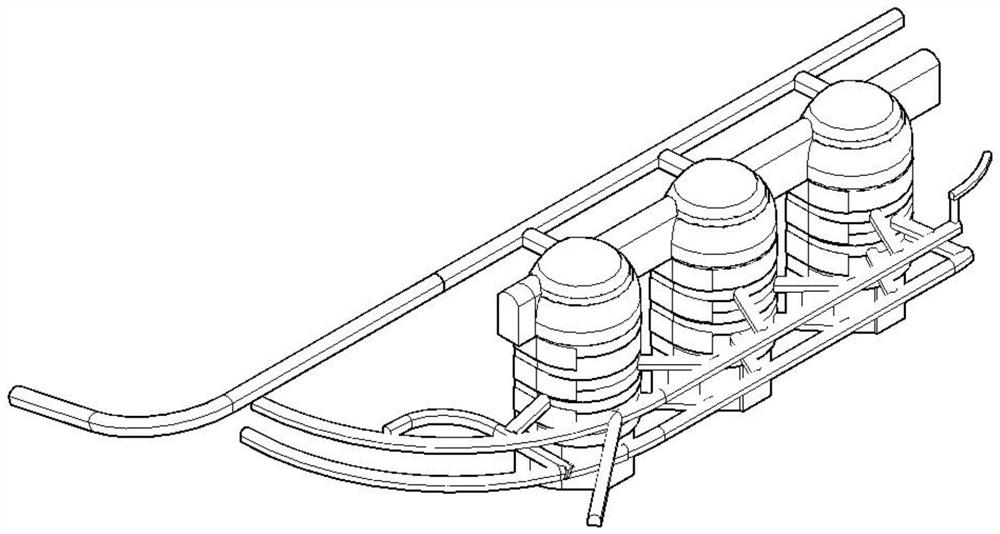

Image

Examples

Embodiment Construction

[0041] In order to facilitate the description of the excavation method provided by the embodiment of the present application, the embodiment of the present application takes the tail adjustment room on the right bank of the Wudongde Hydropower Station with a maximum excavation diameter of 53 m as an example for description.

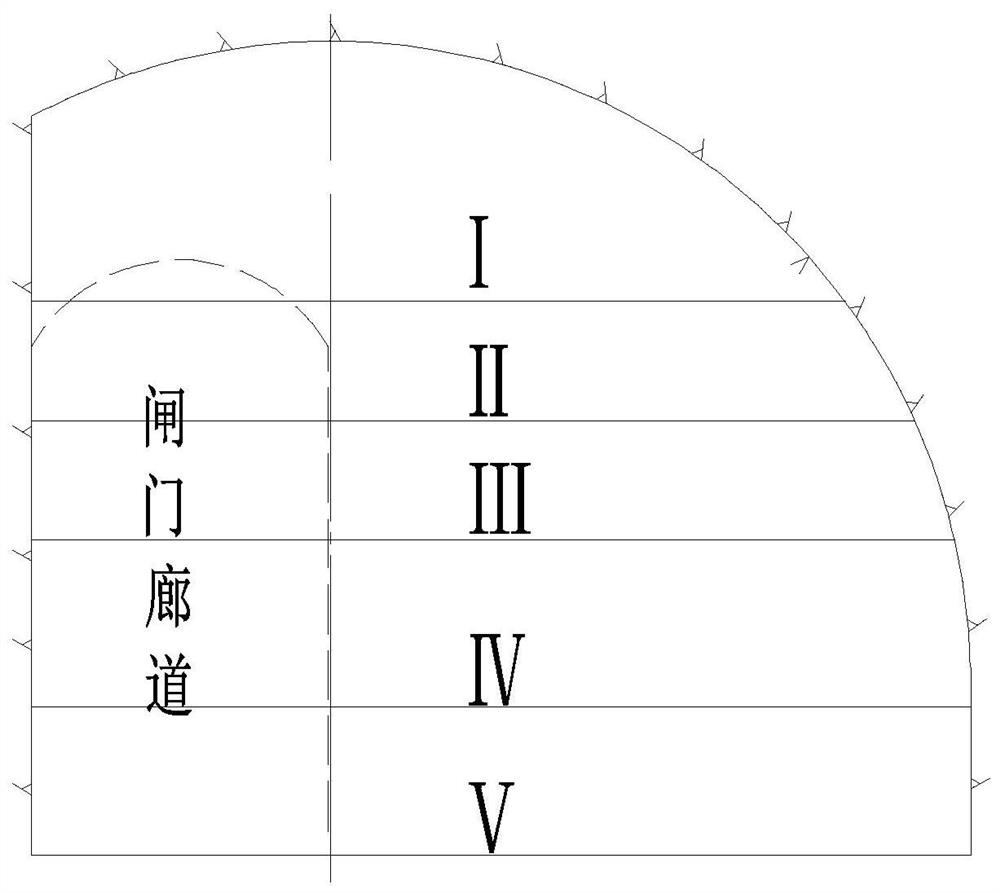

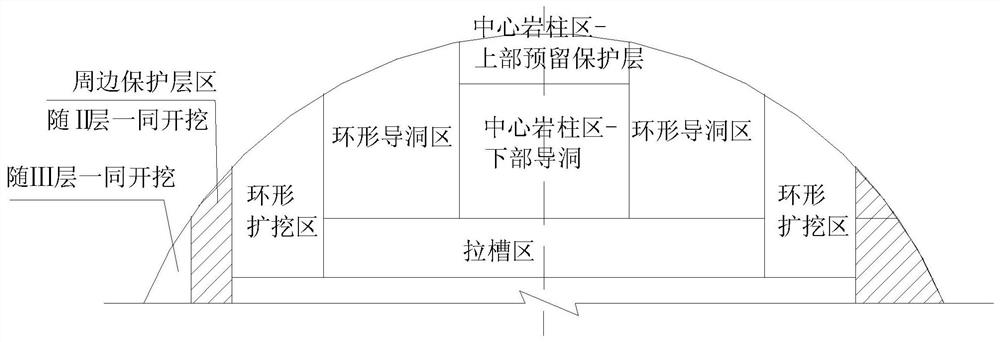

[0042] An embodiment of the present application provides an excavation method for an underground spherical dome. The excavation method includes: dividing the spherical dome from top to bottom into layers I-V; The central rock pillar area, the channel area, the circular expansion area and the surrounding protective layer; the II-V layers are all excavated by blasting in the middle step and reserving protective layers on both sides.

[0043] In order to ensure the quality and safety of the excavation, before the excavation of the underground spherical dome, it also includes:

[0044] S01: Simulate the excavation of the underground spherical crown dome by us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com