Energy collecting blasting and smooth surface blasting combined control blasting method

A technology of smooth blasting and combined control, which is applied in blasting and other directions, can solve the problems of not being able to adapt to retaining rock mass, and achieve the effect of improving the forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

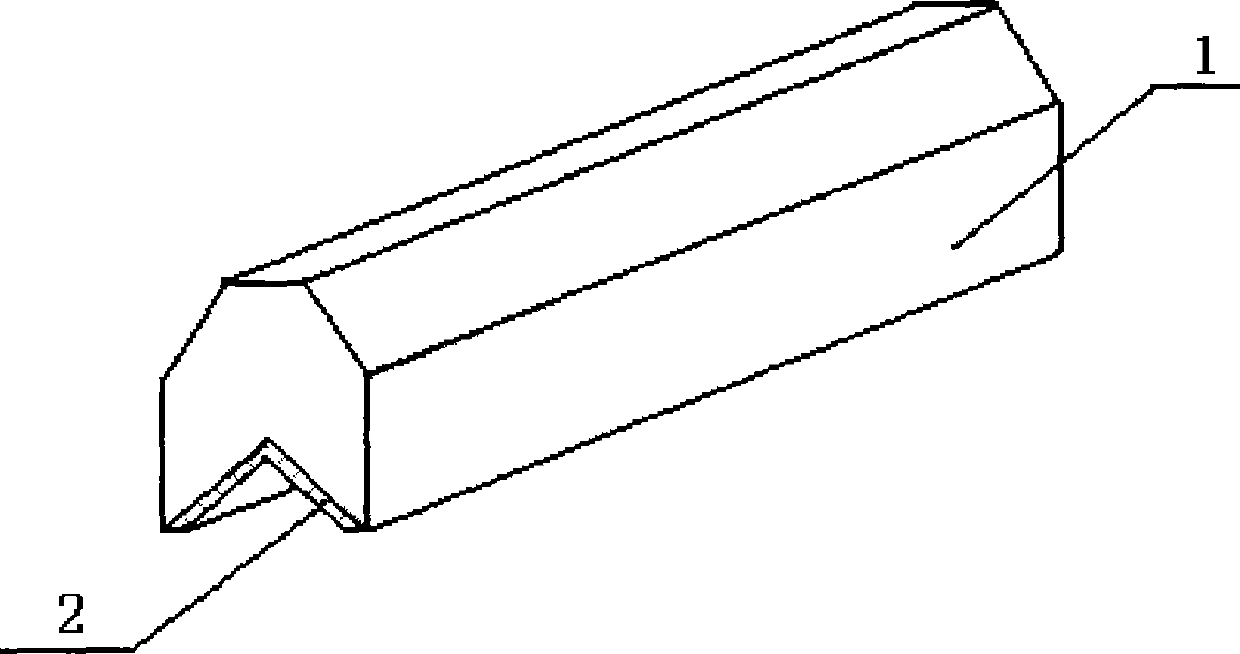

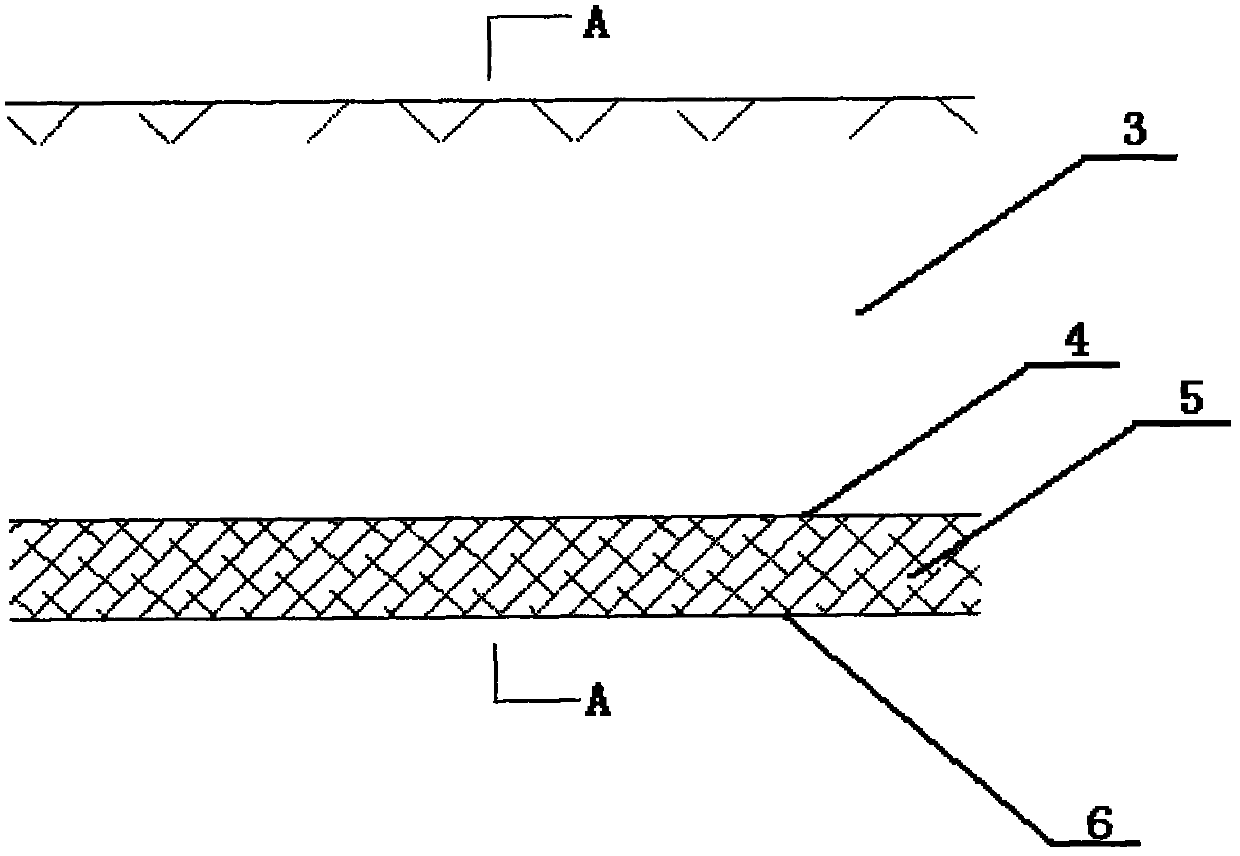

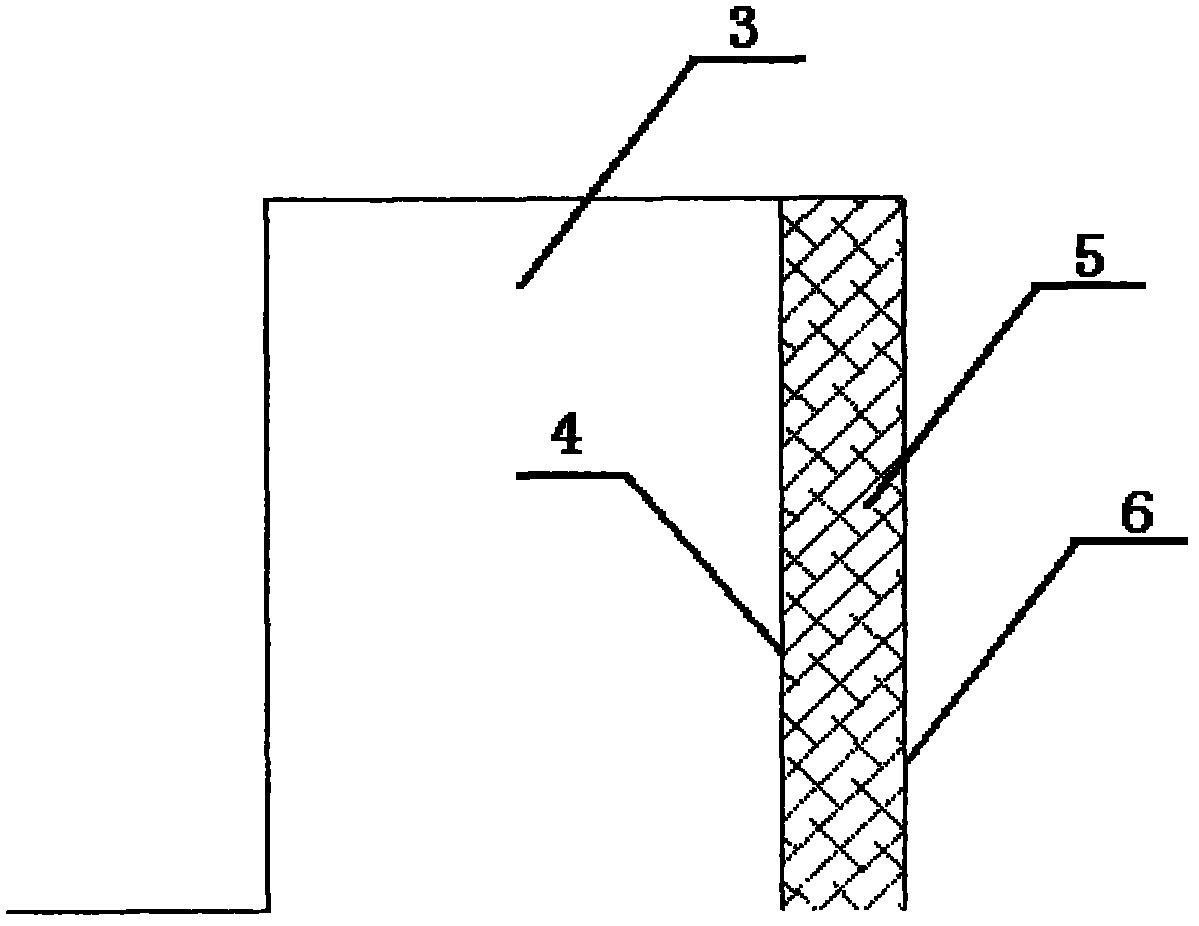

[0028] Embodiment 1 Concentrated blasting and smooth surface blasting combined control blasting method (see figure 2 , image 3 ), including the following steps:

[0029] (1) Delineate the peripheral contour line of the blasting excavation area according to the design requirements of the differential blasting, and arrange the differential blasting holes in the main blasting excavation area 3 .

[0030] (2) Arrange smooth blasting holes along the contour line of the blasting excavation area.

[0031] Among them: the diameter of the smooth blast hole is 38-42mm.

[0032] (3) Embedding a linear drug-shaped cover 2 in a linear shape shaped charge bag 1 with a cavity to make a linear shape shaped energy explosive cutter (see figure 1 ). Reserve the smooth surface layer 5 within the perimeter contour line of the blasting excavation area to be cut by the side of the main blasting excavation area 3 to form a line-shaped energy-concentrating explosion cutter arranged above or in f...

Embodiment 2

[0040] Embodiment 2 The joint controlled blasting method of concentrated energy blasting and smooth blasting includes the following steps:

[0041] (1) Delineate the peripheral contour line of the blasting excavation area according to the design requirements of the differential blasting, and arrange the differential blasting holes in the main blasting excavation area 3 .

[0042] (2) Arrange smooth blasting holes along the contour line of the blasting excavation area.

[0043] Among them: the diameter of the smooth blast hole is 38-42mm.

[0044] (3) Embedding a linear drug-shaped cover 2 in a linear shape shaped charge bag 1 with a cavity to make a linear shape shaped energy explosive cutter (see figure 1 ). Reserve the smooth surface layer 5 within the perimeter contour line of the blasting excavation area to be cut by the side of the main blasting excavation area 3 to form a line-shaped energy-concentrating explosion cutter arranged above or in front of the crack plane 4 ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com