Tunnel milling and excavation in medium-hard strata and supporting mechanized construction method

A technology for hard ground and milling machines, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc. It can solve problems such as the inability to use blasting construction, large blasting disturbance, and surface deformation, so as to reduce the surrounding rock support level, surrounding rock Less disturbance and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

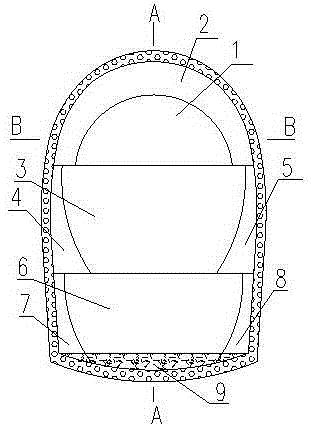

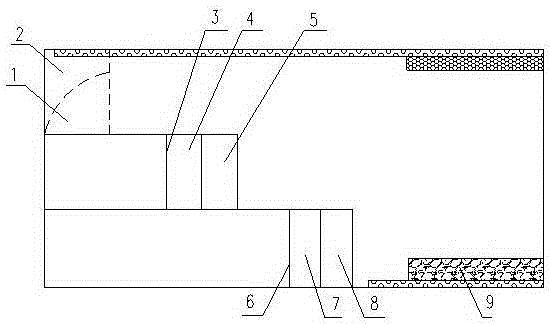

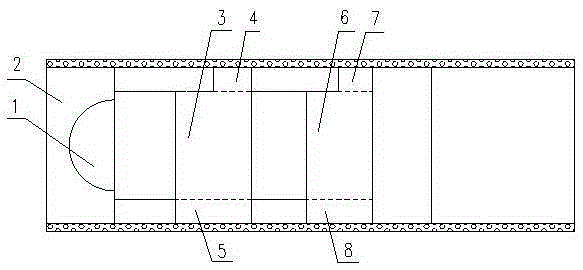

[0027] The present invention will be further described in detail below in conjunction with accompanying drawings and specific examples: a kind of medium-hard formation tunnel milling and supporting mechanized construction method, according to the three-step method, the medium-hard formation tunnel cross section is divided into figure 1 , attached figure 2 And attached image 3 The parts shown are the central part of the upper step 1, the outer part of the upper step center 2, the core soil part of the middle step 3, the left side wall part 4 of the middle step, the right side wall part 5 of the middle step, and the core soil part 6 of the lower step , The left side wall part 7 of the lower step and the right side wall part 8 of the lower step carry out the following steps for the construction of each part:

[0028] A. Use Doosan DXB160 large breaker to excavate the central part 1 of the upper step until the drill rod drifts, so that the excavation working face becomes a semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com