Mechanical-electrical-hydraulic hybrid intelligent variable moment type engine

An electro-mechanical-hydraulic and engine technology, applied in variable torque engine, intelligent, electro-mechanical-hydraulic hybrid fields, can solve the problems of wasting energy and reducing the service life of brake components, and achieve the effect of saving resources and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

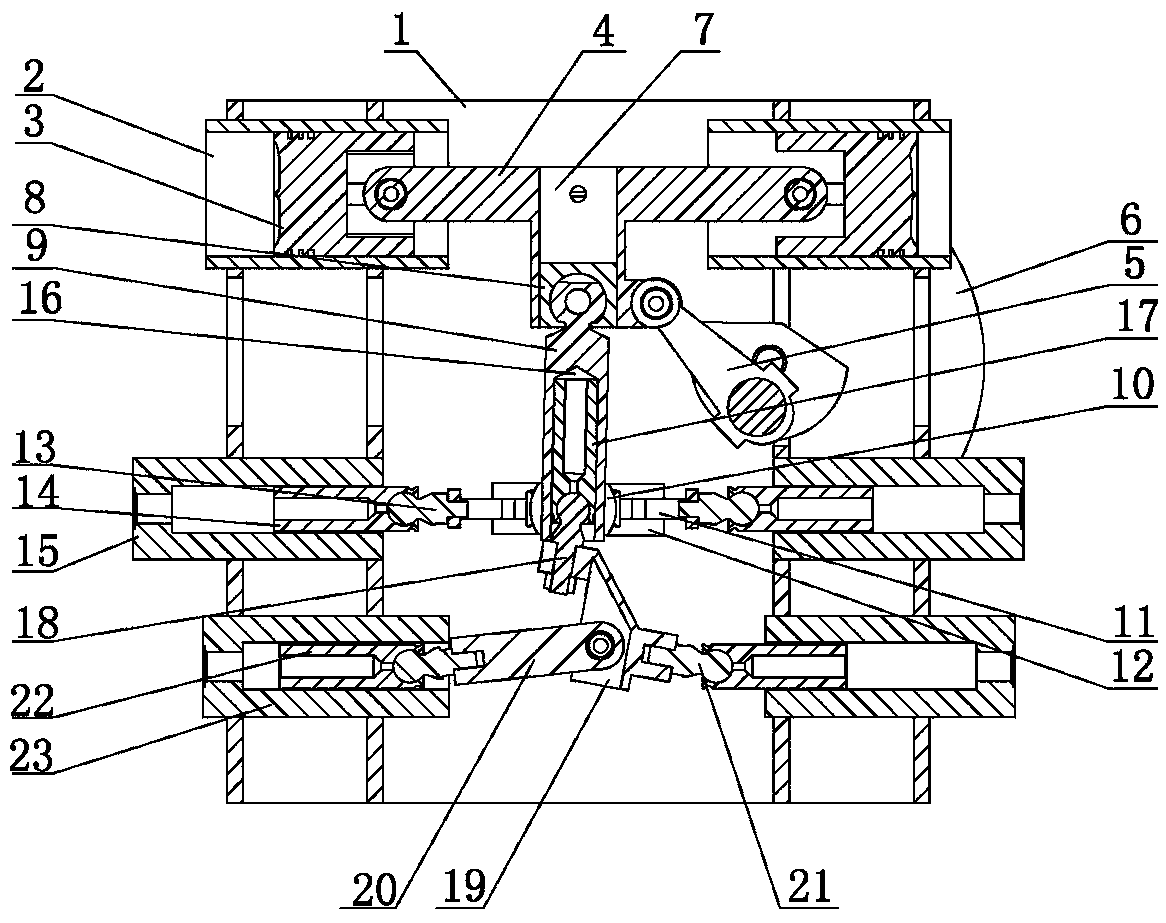

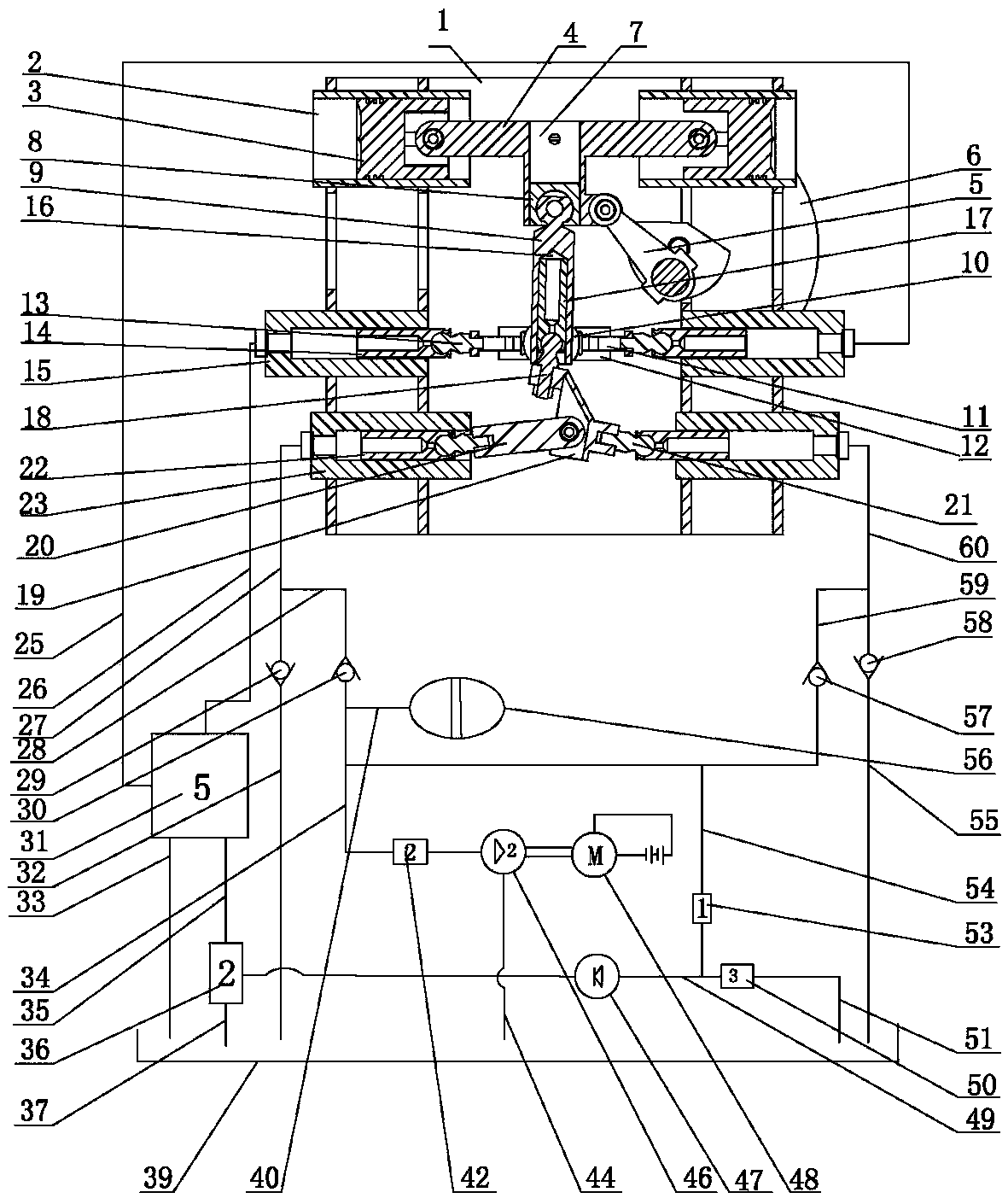

[0009] An electromechanical-hydraulic hybrid, intelligent, variable torque engine according to the present invention, such as figure 1 As shown, including the installation frame 1, two piston cylinders 2 are arranged side by side on the upper side of the installation frame 1, and each piston cylinder 2 is equipped with a piston head 3, and the piston head 3 reciprocates in the piston cylinder 2 to give the whole mechanism Provide power. The two piston heads 3 are connected by a T-shaped rod 4, and the two ends of the T-shaped rod 4 are respectively hinged with the piston head 3 on the same side, and one side of the lower end of the T-shaped rod 4 is hinged with a crank connecting rod 5, and the crank connecting rod 5 coaxially is equipped with flywheel 6, and described flywheel 6 and crank connecting rod 5 are used for the starting of whole device, and above-mentioned all structures are identical with existing internal structure of engine. On the back side of the T-shaped bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com