Method and system for judging rapid refrigerant leakage in refrigeration system

A technology of a refrigeration system and a determination method, which is applied to refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of refrigerant leakage, inability to quickly leak refrigerant, etc., and achieve the effect of no investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The method for judging the rapid leakage of refrigerant in the refrigeration system of this embodiment includes the following steps:

[0040] Step 1. Prestore a correspondence table 1 between the motor winding temperature and the operating frequency of the compressor in the refrigeration system, and preset the temperature difference threshold corresponding to the motor winding temperature of the compressor at the corresponding operating frequency; where, considering the frequency of the compressor The actual influencing factors, the operating frequency of the compressor can be jointly determined by the system refrigerant demand and the opening degree of the corresponding electronic expansion valve.

[0041] Step 2. Step 2. After the refrigeration system is started, calculate the instantaneous temperature of the compressor motor winding and obtain the operating frequency of the compressor at this time.

[0042] Step 3. Obtain the motor winding temperature corresponding t...

Embodiment 2

[0051] In this embodiment 2, in addition to applying steps 1-4 in embodiment 1, compared with embodiment 1, in step 1 of this embodiment, the corresponding relationship table between the temperature difference threshold and the exhaust port temperature is also pre-stored in the refrigeration system two.

[0052] Moreover, compared with Embodiment 1, in Step 2 of this embodiment, considering the influence of ambient temperature on the refrigeration system, after the refrigeration system is started, when calculating the instantaneous temperature of the motor winding and obtaining the operating frequency of the compressor at this time, The exhaust port temperature at this time is also acquired.

[0053] Moreover, compared with Embodiment 1, in step 4 of this embodiment, when judging whether the temperature difference is within the preset threshold range, considering the influence of ambient temperature on the refrigeration system, according to the obtained exhaust port temperatur...

Embodiment 3

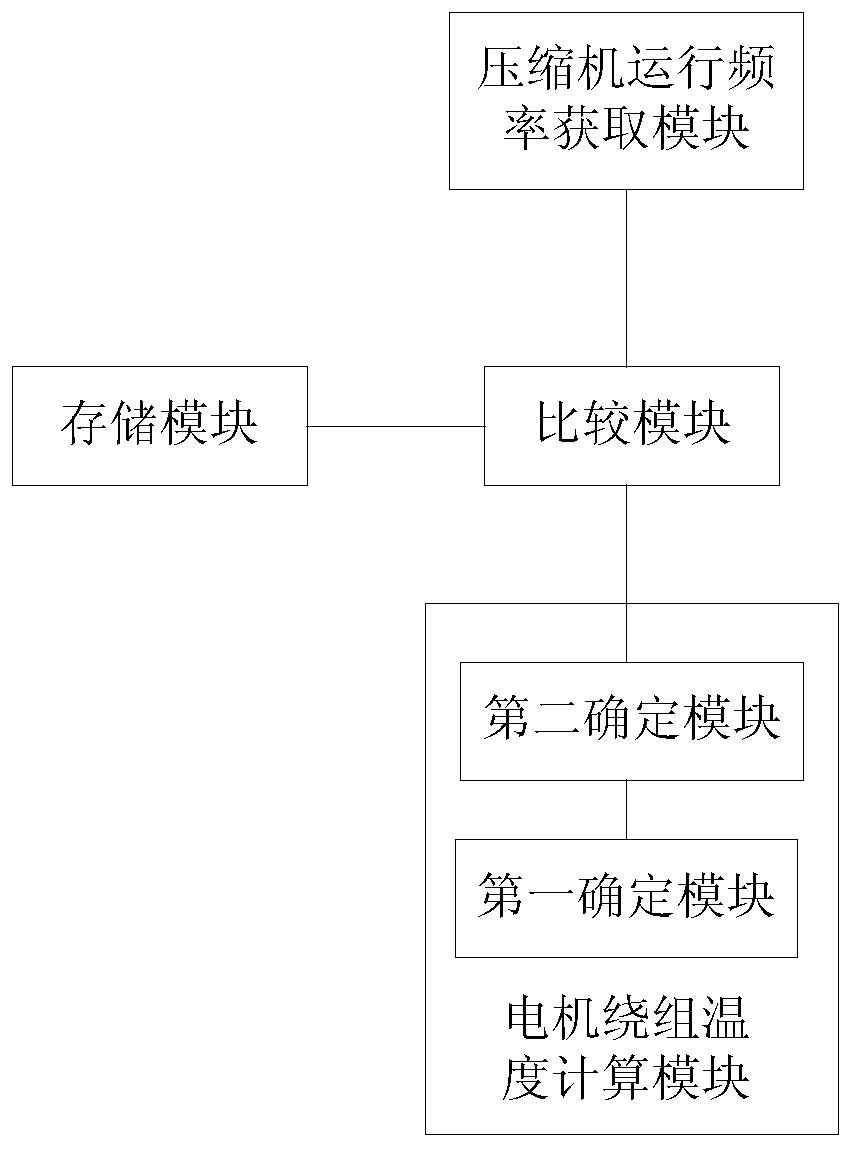

[0057] The system for determining rapid refrigerant leakage in a refrigeration system in this embodiment can be applied to the method for determining rapid refrigerant leakage in a refrigeration system mentioned in Embodiment 1 or Embodiment 2. Here, only the method applied in Embodiment 1 will be described in detail for the system of this embodiment. The system for judging the rapid leakage of refrigerant in the refrigeration system of this embodiment includes a storage module, a compressor operating frequency acquisition module, a motor winding temperature calculation module and Comparison module, its structural block diagram see figure 1 ,in:

[0058] The storage module stores the corresponding relationship table 1 between the motor winding temperature and the compressor operating frequency, as well as the preset temperature difference threshold corresponding to the motor winding temperature of the compressor at the corresponding operating frequency; the compressor operatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com