Universal Device for Ball Grid Array Device Planting

A ball grid array and general-purpose device technology, which is applied in the manufacturing of semiconductor devices, electric solid-state devices, and semiconductor/solid-state devices, etc., can solve the problems of high operator requirements, delayed production schedule, and missing solder balls, and achieves a simple structure of the device. Realize the effect of fast missing installation and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

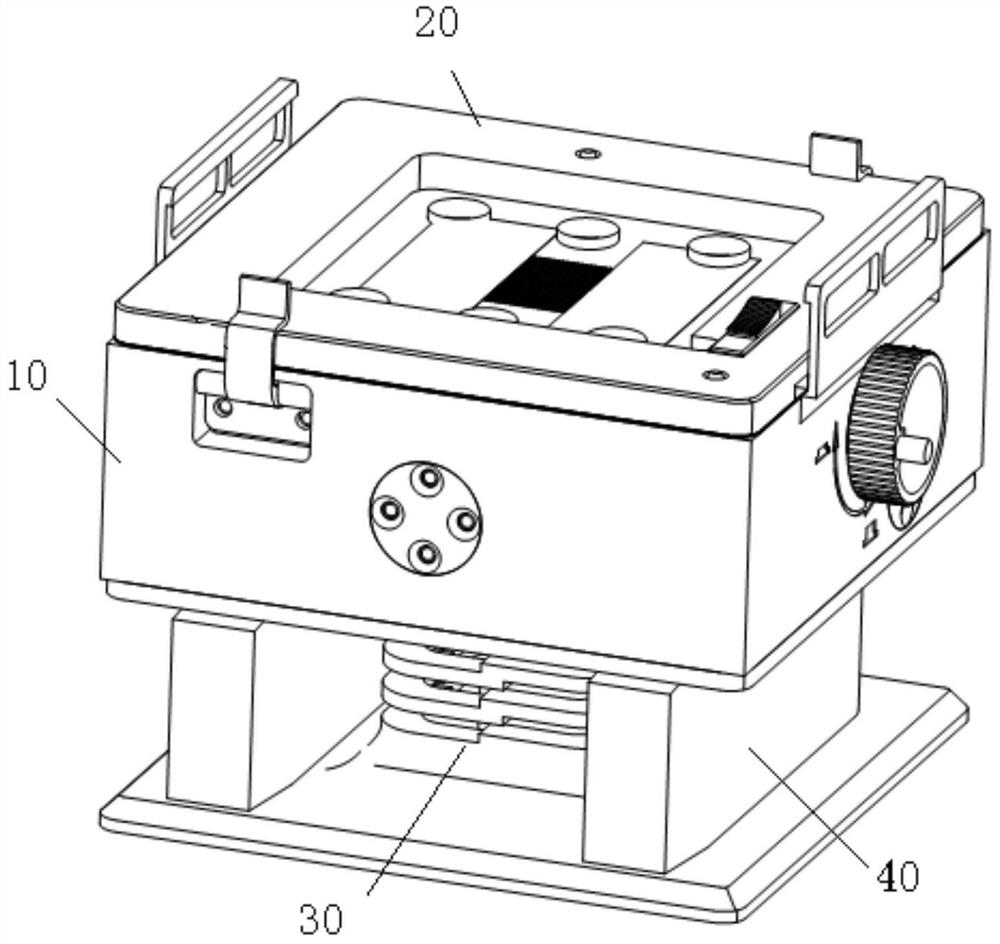

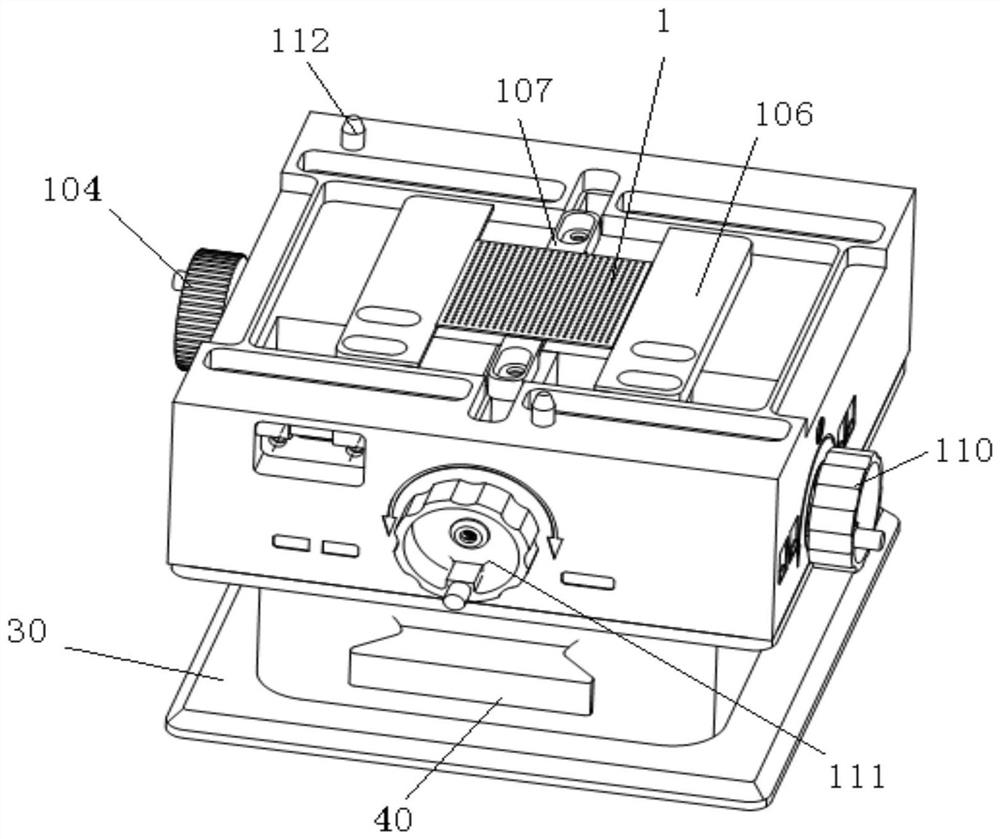

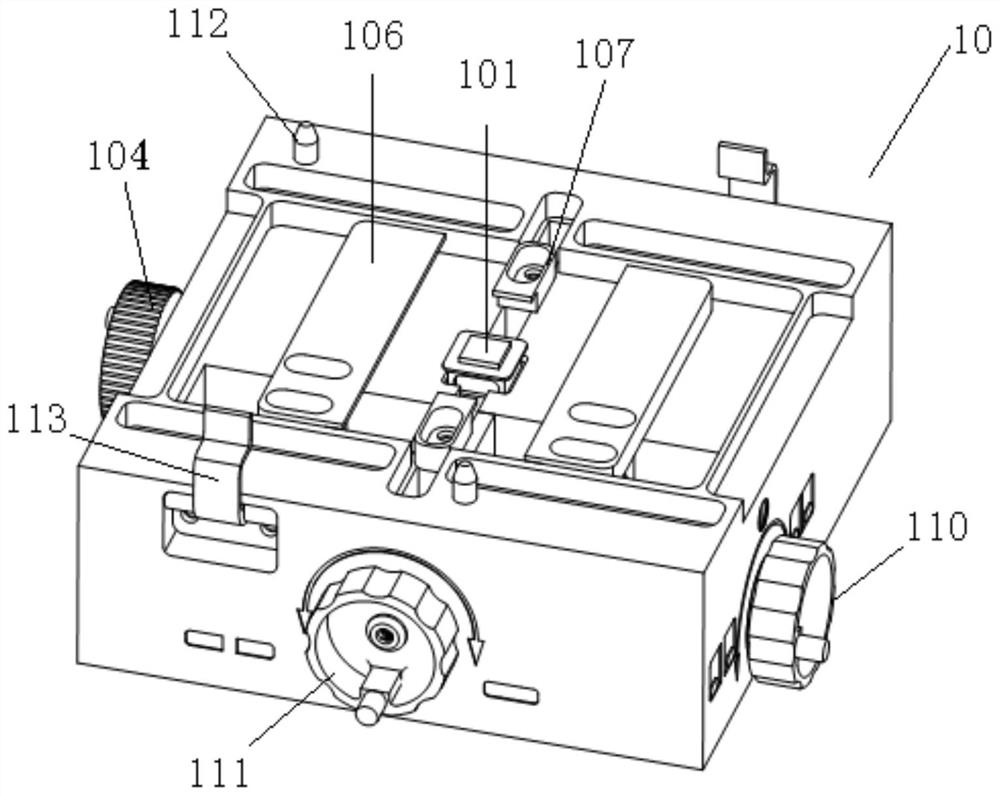

[0028] refer to Figure 1-Figure 9 As shown, in the preferred embodiment described below, a general device for planting balls of ball grid array devices includes: a general solder ball drain plate 20 installed above the ball planting table 10, an elastic base 30 below the ball planting table 10 and The U-shaped card slot is characterized in that: the central part of the ball planting pool of the inner cavity frame of the ball planting table 10 is provided with a lifting support block 101 that drives and places the ball grid array device substrate 1 on it to rise / fall synchronously, and the height distance is adjustable. The lifting support block 101 is symmetrical, the auxiliary clamping slider 107 that slides along the wide-side suspension beam slide rail, and the main clamping slider 106 that slides along the chute on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com