Anti-static film and preparation method thereof

An anti-static and anti-static layer technology, used in pressure-sensitive films/sheets, film/sheet adhesives, conductive coatings, etc., which can solve the problems of cumbersome washing with water, poor anti-static effect, and easy drying of water films. Loss and other problems, to reduce the possibility of electrostatic accumulation, improve anti-static performance, and achieve the effect of good anti-static

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of antistatic film is made according to the following preparation process:

[0048] S1. Substrate film formation: Weigh 80g of low-density polyethylene and put it in an oven at 80°C to dry for 2 hours, then put it into the extruder. Section 200 ° C, head 170 ° C, under the condition of screw speed of 65 r / min, extrude into a film to obtain the substrate;

[0049] S2. Substrate post-treatment: Put the substrate in the corona treatment machine, and pass through a pair of electrodes on both sides of the substrate. Corona treatment is carried out on both sides of the material to obtain a modified base material;

[0050] S3, the preparation of adhesive layer:

[0051] Weigh 35g butyl acrylate, 25g methyl methacrylate, 25g acrylic acid, 60g deionized water, 1g acrylic polyether phosphate and 1g azobisisobutyronitrile;

[0052]Stir acrylic acid polyether phosphate and deionized water to prepare an emulsion, then add butyl acrylate, methyl methacrylate and acrylic aci...

Embodiment 2

[0060] An antistatic film, prepared on the basis of Example 1, differs from Example 1 in that 0.6g of graphite (average particle diameter is 100nm) is added in step S2.

Embodiment 3-7

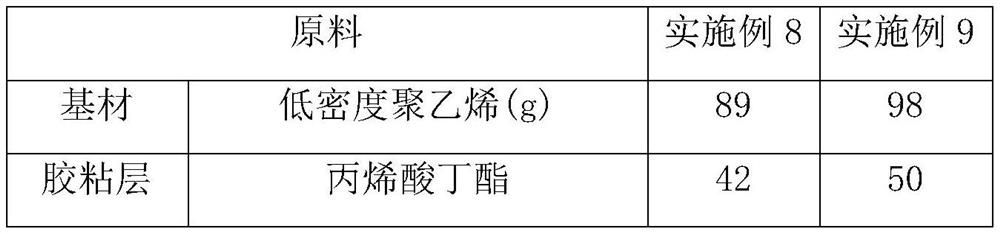

[0062] A kind of antistatic film, prepared on the basis of embodiment 2, differs from embodiment 2 in that: the conductive filler added in the step S4 is different, and the average particle diameter of carbon nanotube, graphite powder, copper powder is 40nm, The specific composition is shown in Table 2 below:

[0063] Table 2. Composition of conductive fillers

[0064] Conductive filler Example 3 Example 4 Example 5 Example 6 Example 7 Carbon nanotubes (g) / / / 5 4 Graphite (g) 10 / 5 5 3 Copper (g) / 10 5 / 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com