A terminal heat dissipation structure and a heat dissipation control method

A technology of heat dissipation structure and control method, which is applied to instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of easy entry of dust in terminals, affecting user experience, and damaging the service life of mobile terminals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

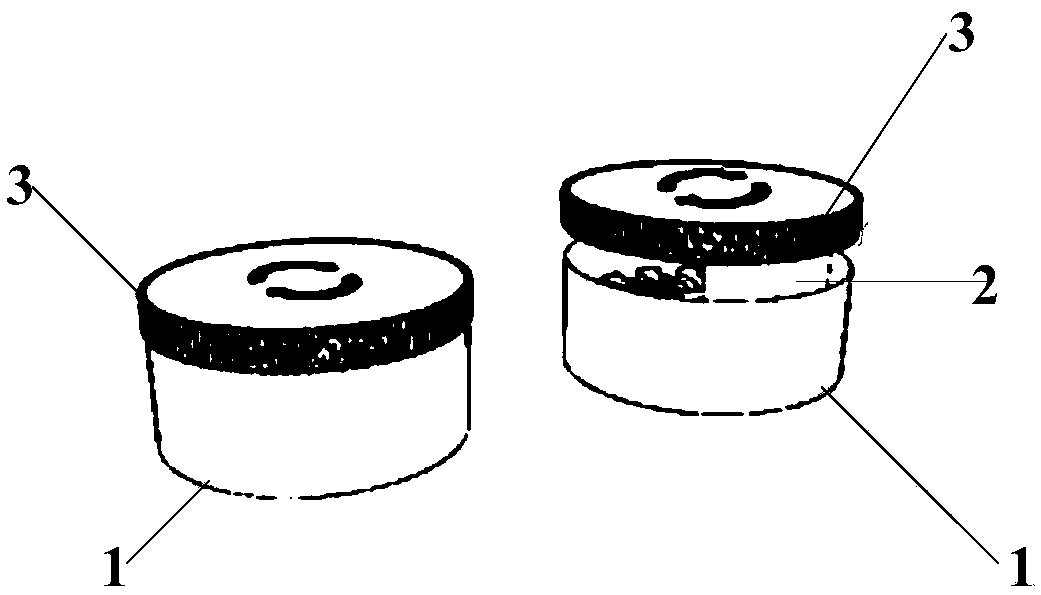

[0059] Aiming at the technical problems that current mobile terminals adopt air cooling technology for heat dissipation, the terminal is prone to ash ingress, which will damage the service life of the mobile terminal and affect the user experience. This embodiment provides a terminal heat dissipation structure. The heat dissipation structure It can be applied to mobile terminals that adopt air-cooling technology for heat dissipation. see figure 2 As shown, the heat dissipation structure includes a heat dissipation wall 1 enclosing a heat dissipation channel, a connecting part 2 arranged in the heat dissipation channel that can be stretched up and down, and a dustproof cover 3 connected to one end of the connecting part 2 .

[0060] In this embodiment, in one state, the dust cover 3 can abut against the heat dissipation wall 1 so as to close the heat dissipation channel. At this time, there is no heat dissipation vent or the heat dissipation vent is closed, which is applicabl...

no. 2 example

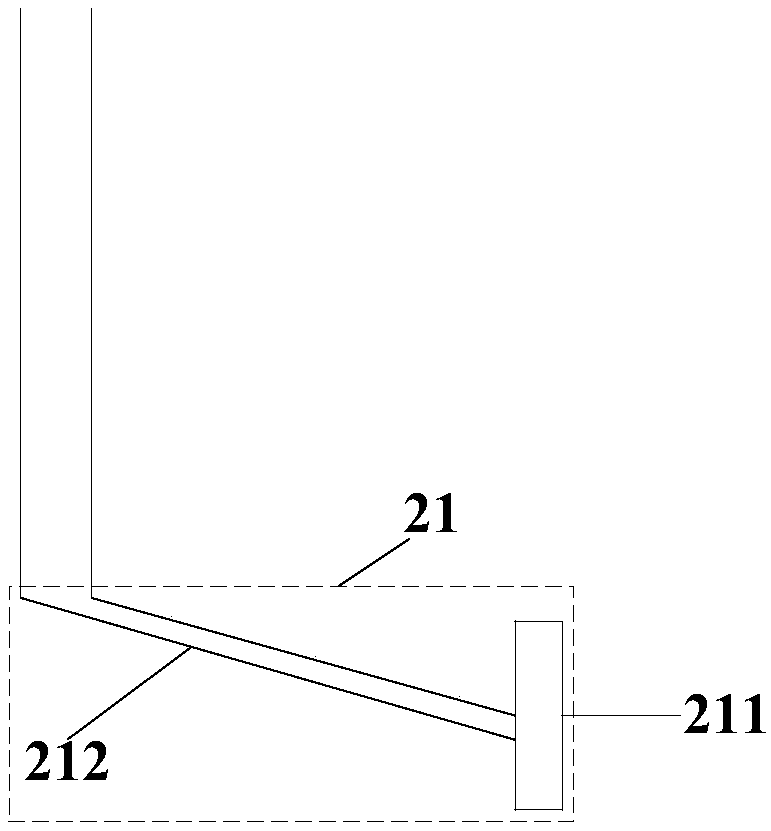

[0081] This embodiment proposes a heat dissipation control method on the basis of the terminal heat dissipation structure of the motor in the first embodiment above. see Figure 6 shown, including:

[0082] S601: Detect the current state of the terminal;

[0083] In this embodiment, the terminal can monitor the state of the terminal itself in real time through a detection program.

[0084]S602: When it is detected that the current state of the terminal satisfies the preset heat dissipation condition, turn on the air cooling function and control the rotation of the motor to form a heat dissipation port;

[0085] In this embodiment, the preset heat dissipation condition may include: the terminal starts an application in a preset set, and / or, the temperature of the terminal reaches a preset temperature threshold.

[0086] In this embodiment, the applications in the preset collection may be applications with high energy consumption in the terminal, such as applications such as ...

no. 3 example

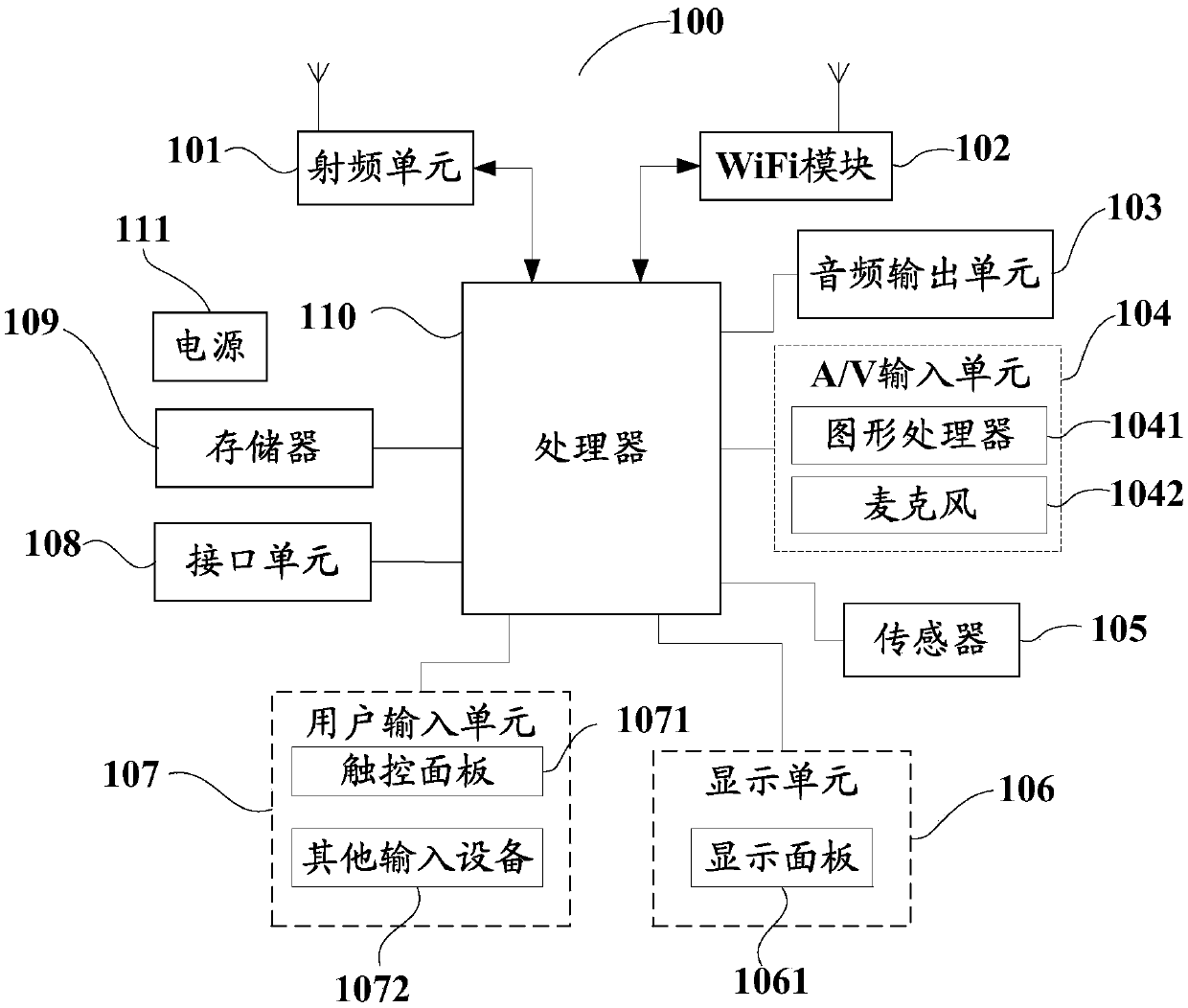

[0095] This embodiment provides a terminal, see Figure 7 As shown, it includes a processor 701 , a memory 702 and a communication bus 703 . in:

[0096] The communication bus 703 is used to realize connection and communication between the processor 701 and the memory 702 .

[0097] The processor 701 is configured to execute one or more programs stored in the memory 702, so as to implement each step of the heat dissipation control method in the second embodiment above.

[0098] This embodiment provides a computer-readable storage medium, such as a floppy disk, a CD, a hard disk, a flash memory, a USB flash drive, a CF card, an SD card, an MMC card, etc., in which a computer-readable storage medium is stored to implement the above steps. Or a plurality of programs, the one or more programs can be executed by one or more processors, so as to implement the steps of the heat dissipation control method in the second embodiment above. I won't repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com