A fast equivalent modeling method for composite thin-walled bolted composite structures

A composite material and combined structure technology, applied in the field of effective modeling, can solve problems such as low computational efficiency, and achieve the effect of reducing the number of grids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

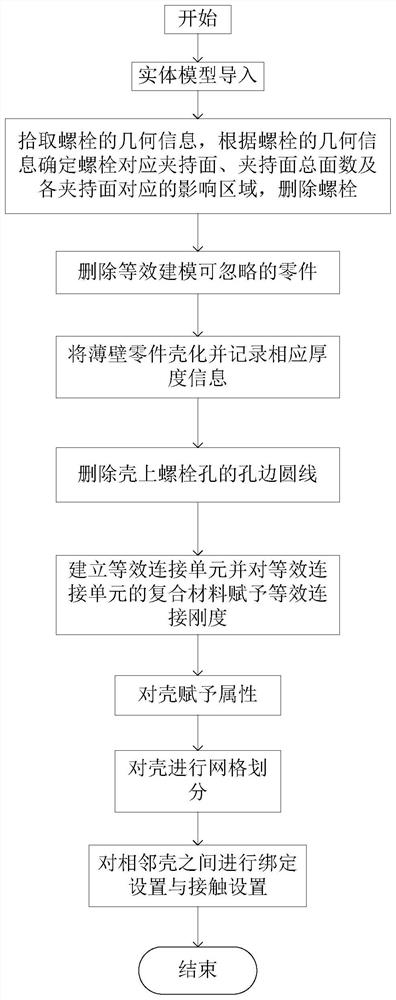

[0037] Embodiment 1: Combining figure 1 To specifically describe this embodiment, a method for rapid equivalent modeling of composite thin-walled bolted composite structures described in this embodiment includes the following steps:

[0038] Step 1. Import the solid model, identify the bolt, pick up the geometric information of the bolt, determine the corresponding clamping surface of the bolt, the total number of clamping surfaces and the affected area corresponding to each clamping surface according to the geometric information of the bolt, and delete the bolt;

[0039] Step 2. Delete the parts that can be ignored by equivalent modeling;

[0040] Step 3. Shell the thin-walled parts and record the corresponding thickness information;

[0041] Step 4. Delete the hole edge circle line of the bolt hole on the shell;

[0042] Step 5. According to the geometric information obtained in step 1, the center of any circular surface of the bolt rod, the corresponding clamping surface ...

specific Embodiment approach 2

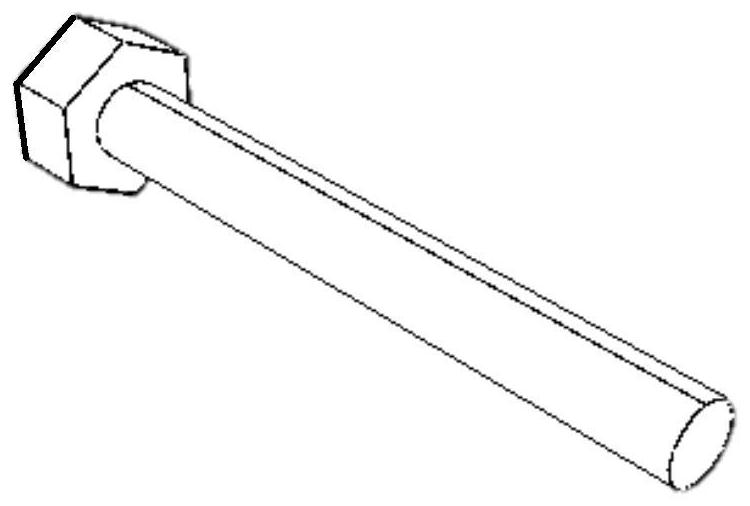

[0049] Specific implementation mode 2: Combining figure 2 This embodiment is specifically described. This embodiment further describes the rapid equivalent modeling method for a composite thin-walled bolted composite structure described in Embodiment 1. In this embodiment, in step 1, the geometry of the bolt is The information includes the center, radius and geometry of the smallest cube occupied by the bolt.

[0050] The only parts really needed in the equivalent model are thin-walled parts (ie, connecting plates) and some thin-walled parts that cannot be shelled, so the first step in modeling is to delete redundant parts. In these parts, the information of the bolt determines the establishment of the equivalent connection unit, so the information of the bolt should be recorded when deleting the bolt. like figure 2 As shown in the figure, according to the characteristics of the cylinder drawing, the number of adjacent surfaces of the bolt shank circular surface is 2, and ...

specific Embodiment approach 3

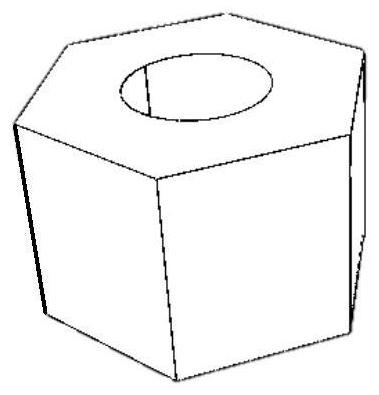

[0052] Specific implementation three: combination image 3 and Figure 4 This embodiment is specifically described. This embodiment further describes the rapid equivalent modeling method for a composite thin-walled bolted composite structure described in Embodiment 2. In this embodiment, in step 2, the value can be ignored. The maximum surface area of the part is the judgment value. When the area of the part is smaller than the judgment value, the part will be deleted, otherwise it will not be deleted.

[0053] This implementation is used to delete redundant small parts. The negligible small parts in the equivalent modeling are mostly nuts, such as image 3 As shown in the figure, because the information of the nut is not needed when establishing the equivalent connection unit, the maximum surface area of the part can be used as a judgment condition, and a reasonable value (determined based on the size of the nut) can be given to delete the nut. For a combined structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com