Dual-layer resin tooth for oral tooth body preparation training

A resin tooth, double-layer technology, applied in the field of stomatology, can solve the problems of difficult to accurately and efficiently control the amount of tooth preparation and the shape of the preparation, the edge is not smooth and continuous, and the degree of polymerization is large, so as to achieve accurate judgment and mastery. and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the double-layer resin tooth provided by the invention can adopt CAD / CAM method or injection molding method.

[0044] The CAD / CAM method provided by the invention comprises the steps:

[0045] Use the existing model to prepare the standard form of the inner layer structure, and then collect the model data through the scanner, the data is designed and adjusted through the design software, the output file is sent to the processing equipment, and inserted into the selected material suitable for the inner layer structure material , the inner layer structure of the standard form can be produced in batches;

[0046] On the basis of the collected model data of the inner structure, the standard external shape is designed through the design software, that is, the shape of the enamel part, and the file is output to the processing equipment, and the material suitable for the outer structure material is selected for processing, which can be mass-produced ...

Embodiment 1

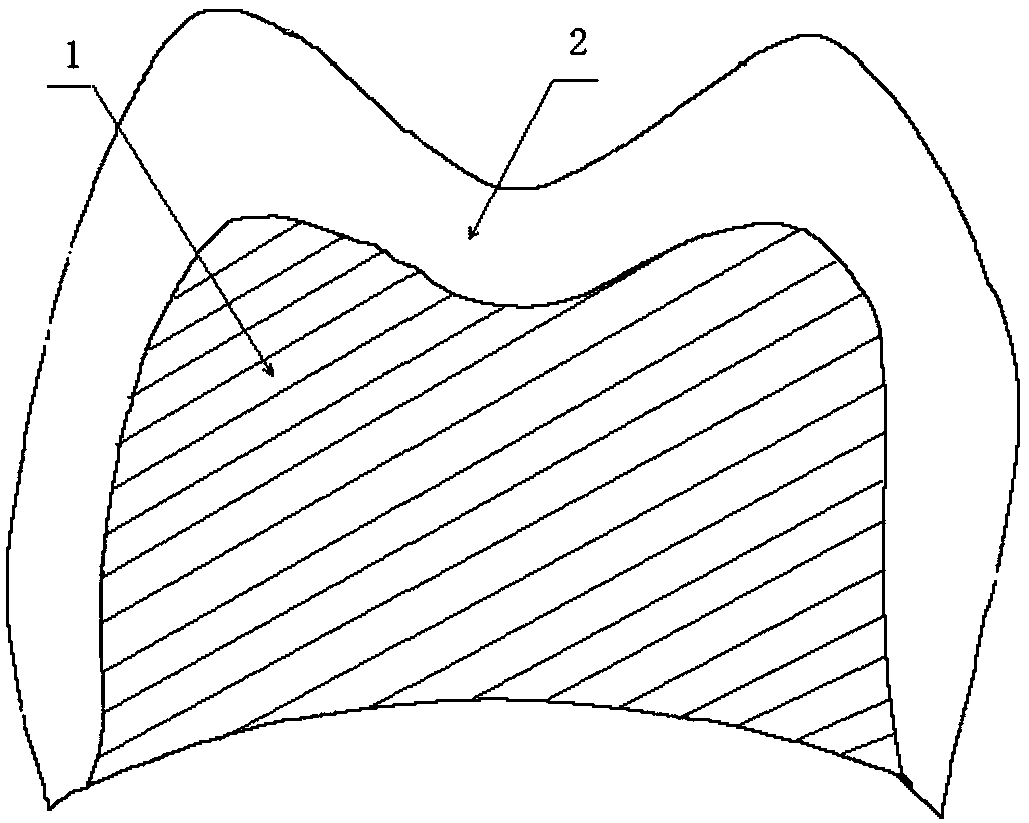

[0056] Such as figure 1 As shown, the double-layer resin tooth used for oral tooth preparation training includes an inner structure 1 and an outer structure 2, wherein the inner structure is a standard preparation shape, the outer structure is a standard crown shape, and the outer structure The color of the structure is white, the color of the inner structure is yellow, and the hardness of the material of the outer structure is smaller than that of the material of the inner structure;

[0057] The material of the outer structure is polymethyl methacrylate; the material of the inner structure is inorganic powder added to polymethyl methacrylate; the thickness of the outer structure is 2mm.

[0058] The preparation method of described double-layer resin tooth adopts CAD / CAM method, comprises the steps:

[0059] Use the existing model to prepare the standard form of the inner layer structure, and then collect the model data by scanning the scanner. The data is designed and adjus...

Embodiment 2

[0063] The difference from Example 1 is that the outer structure of the double-layer resin tooth is transparent, and the inner structure is yellow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com