Micro-rib array heat dissipation device provided with synthetic jet actuator and method

A synthetic jet and heat dissipation device technology, which is applied to the structural parts of electrical equipment, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of complex structure of heat dissipation device, inability to meet heat dissipation requirements, and unsatisfactory heat dissipation effect , to achieve the effect of compact structure, easy processing and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

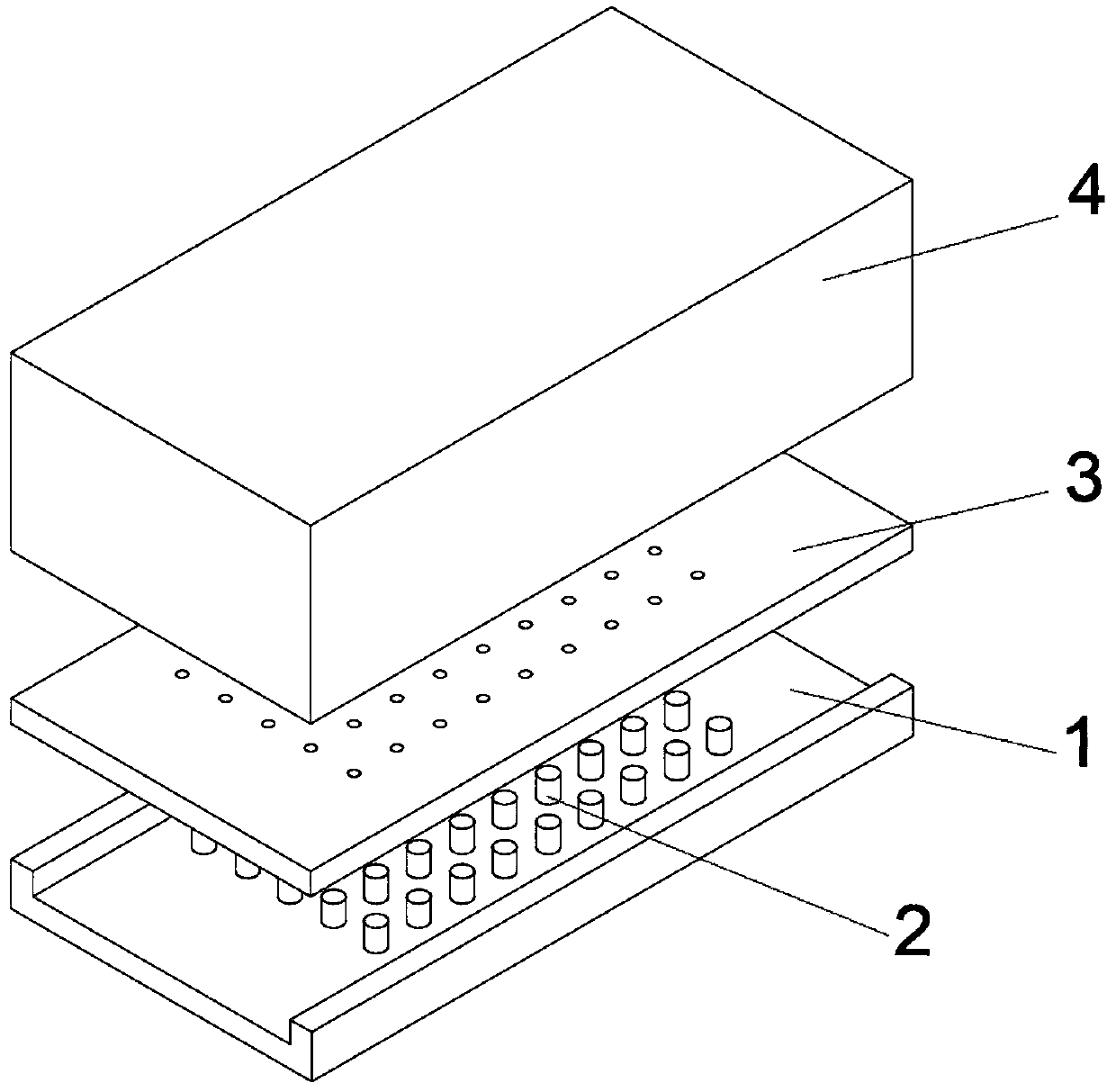

[0018] Such as figure 1 As shown, a micro-rib array cooling device equipped with a synthetic jet actuator, which includes a heat sink substrate 1, a micro-rib array structure 2, a top cover plate 3, and a synthetic jet actuator 4; the heat sink substrate 1 is directly or indirectly connected to the heat source connected; the micro-rib array structure 2 is located above the heat sink substrate 1; the top cover plate 3 is located above the micro-rib array structure 2; the bottom of the synthetic jet actuator 4 is an open structure, located above the top cover plate 3 and assembled with the top cover plate 3 Synthetic jet cavity6.

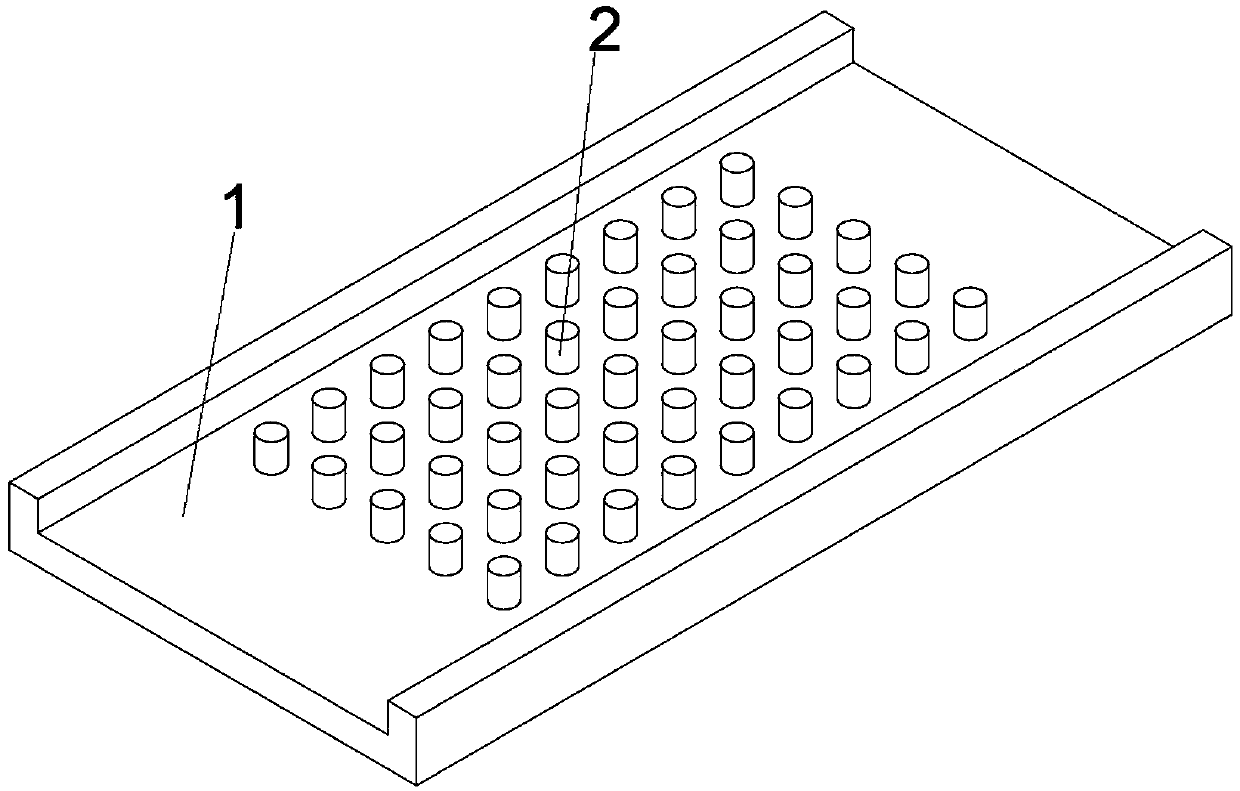

[0019] Such as image 3 As shown, the heat sink substrate 1 is directly connected to the heat-generating part of the electronic device or indirectly through heat pipes and other devices, so as to receive heat from the heat-ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com