Differential lubricant temperature controller

A controller and lubricant technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc. The effect of heating up and stabilizing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following description is merely exemplary in nature and is not intended to limit the invention, application or use.

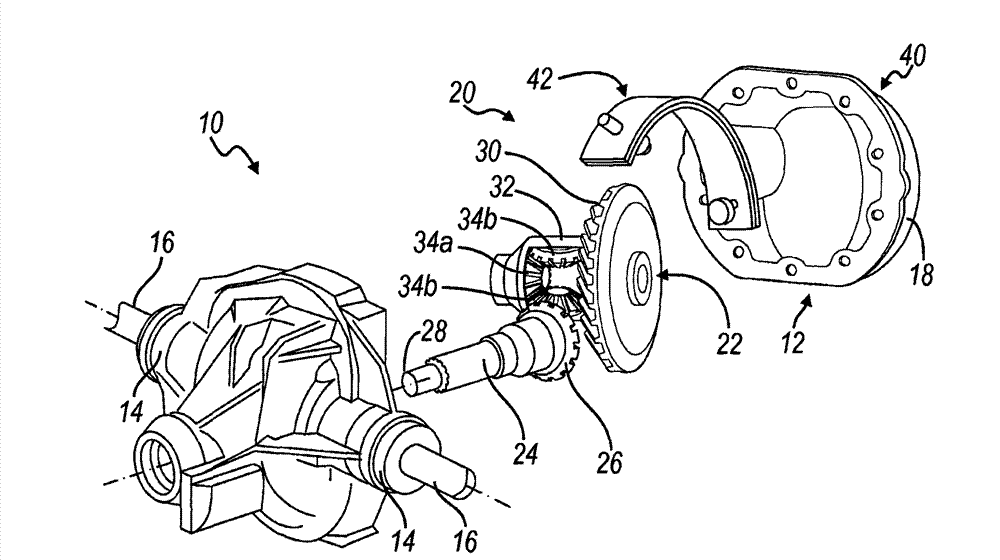

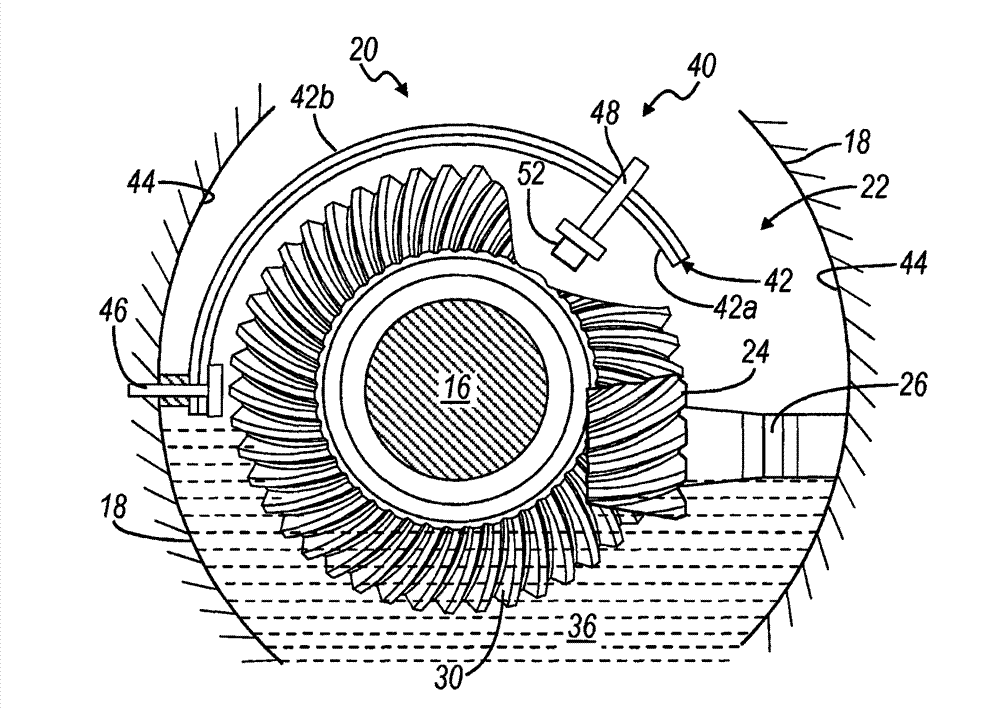

[0028] now refer to figure 1 and 2 , shows a part of the rear axle of the drive train of the motor vehicle and is denoted by reference numeral 10 . The rear axle assembly 10 includes an elongated housing 12 including a pair of oppositely extending coaxial axle housings 14 that receive and support a pair of identical rear axles or half axles 16 . The rear axle assembly 10 also includes a spherical center housing 18 that houses a rear differential assembly 20 . It should be understood that while described herein as a rear differential, as this would be the more common application, the invention is equally suitable, suitable and usable for a front axle or differential of a motor vehicle.

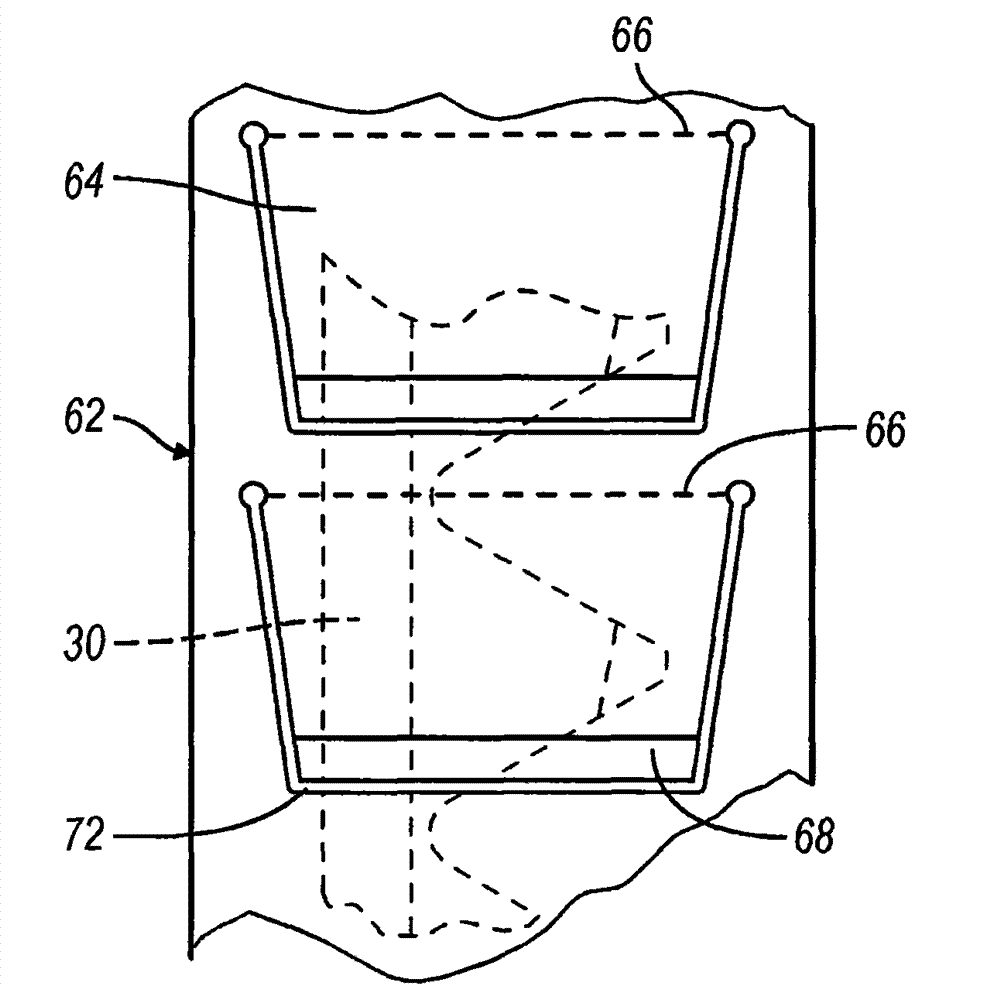

[0029] The rear differential assembly 20 includes a hypoid gearset 22 having a worm or drive gear 24 that rotates about a vehicle longitudinal axis. Although desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com