Adjustable tire vulcanization preheating device

A tire vulcanization and preheating device technology, applied in tires, household appliances, other household appliances, etc., can solve the problems of difficult guarantee, high cost, low utilization rate of superheated water heat energy, etc., to ensure normal circulation, accurate control, Adjustable and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

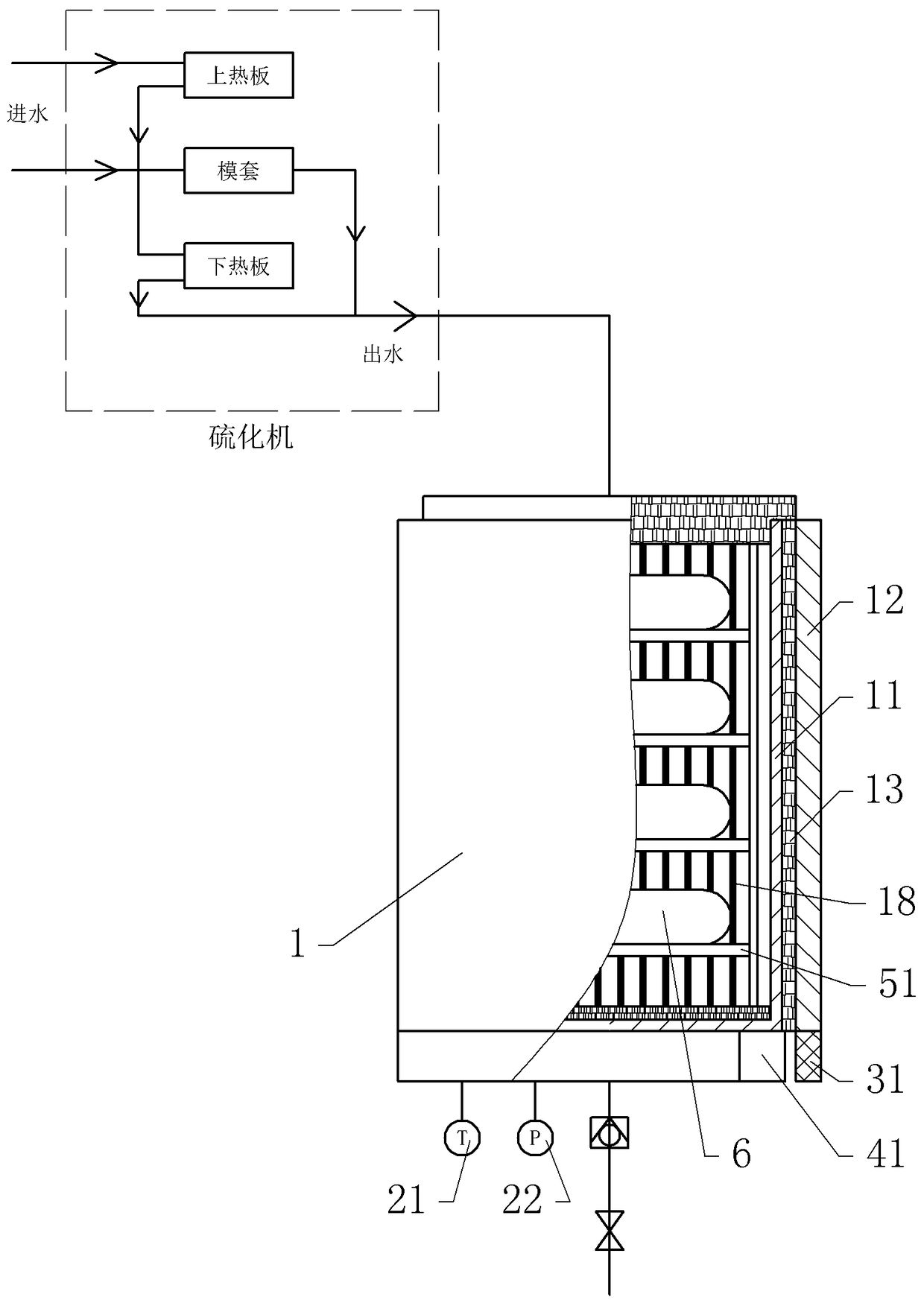

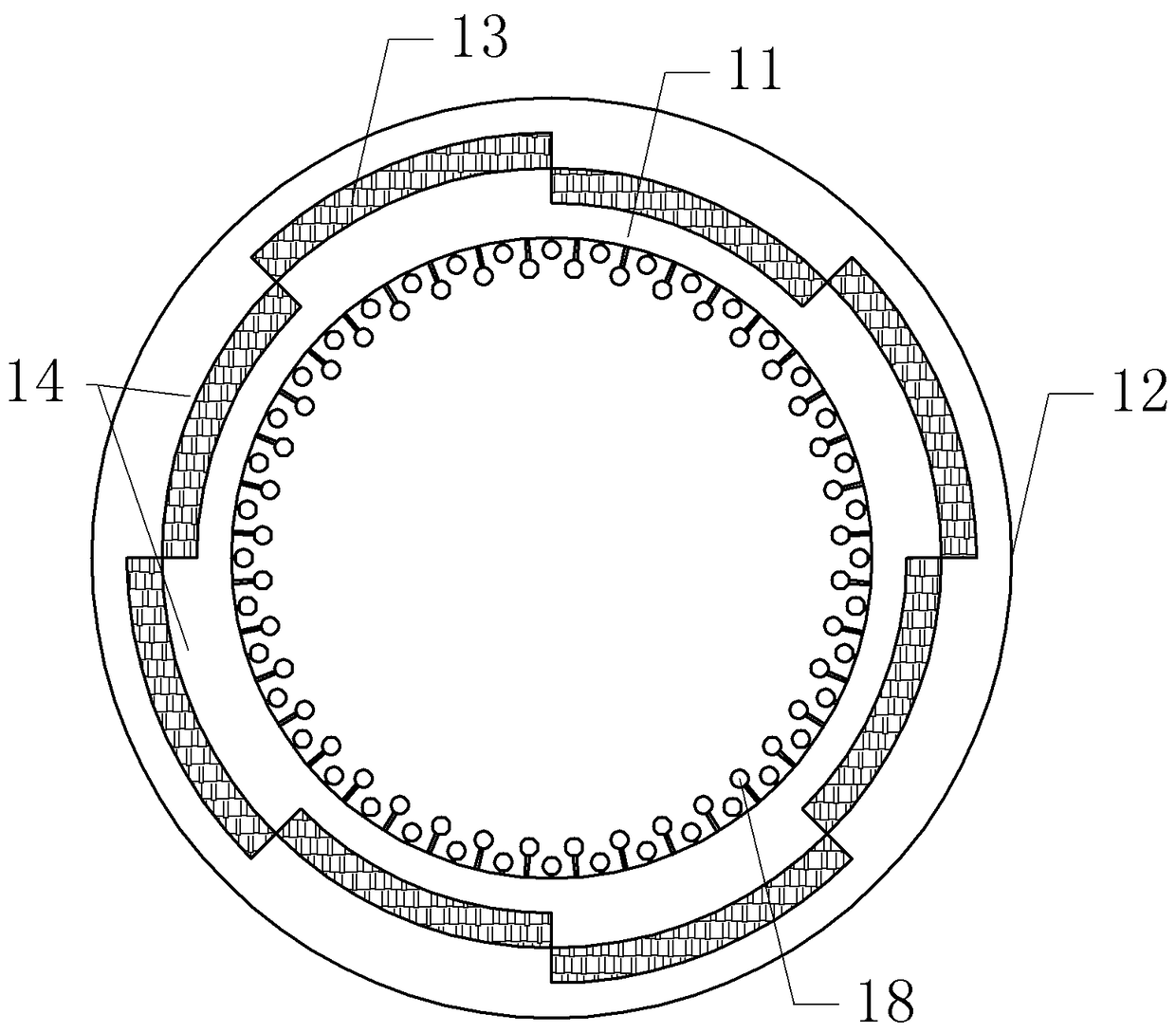

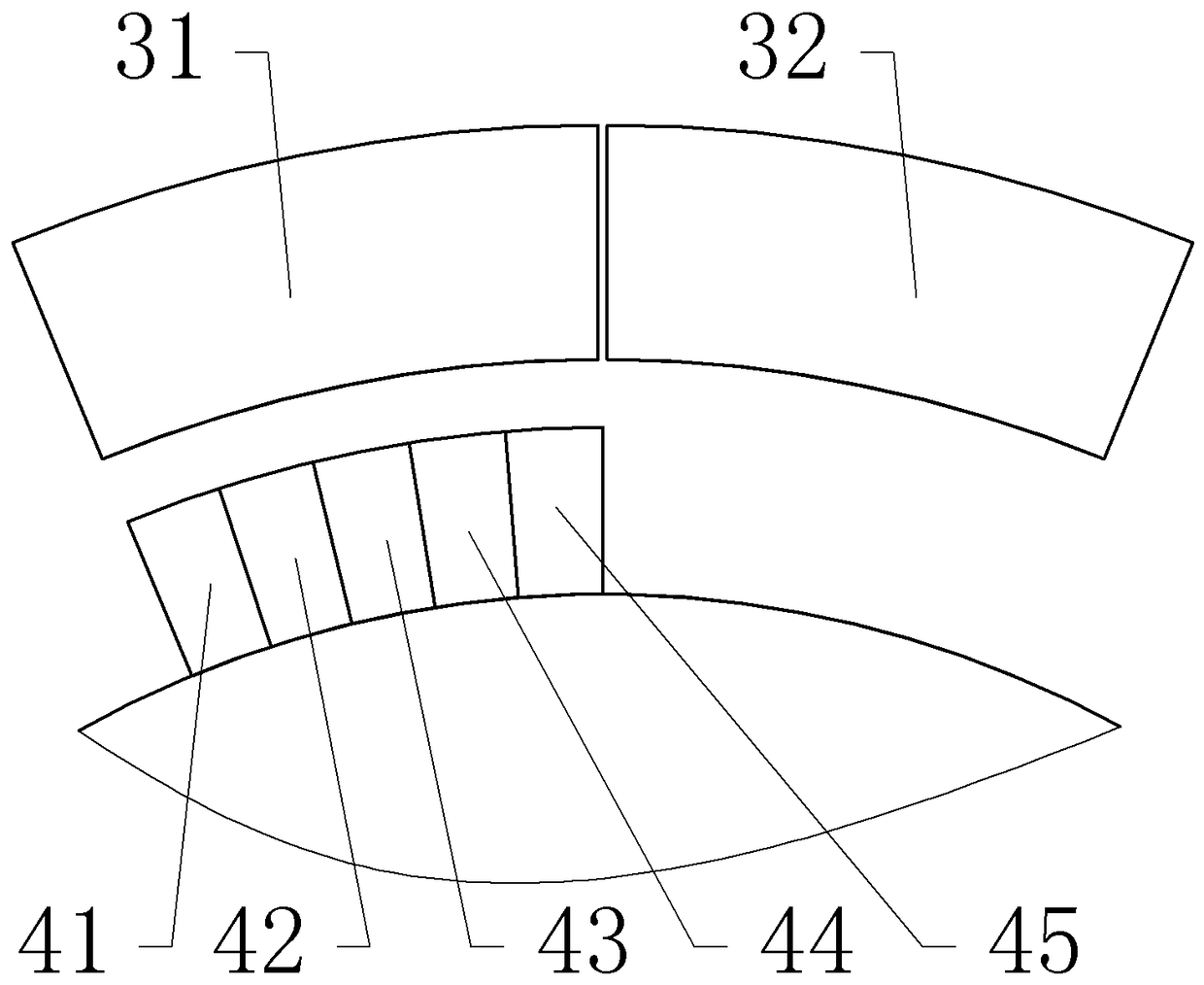

[0023] The reference signs in the drawings of the description include: air preheating box 1, housing 11, regulating cylinder 12, heat insulation layer 13, heat conducting rib 14, heat exchange tube group 18, temperature sensor 21, pressure sensor 22, permanent Magnet one 31, permanent magnet two 32, No. 1 electromagnet 41, No. 2 electromagnet 42, No. 3 electromagnet 43, No. 4 electromagnet 44, No. 5 electromagnet 45, bracket 51, tire blank 6.

[0024] The embodiment is basically as figure 1 , figure 2 , image 3 Shown:

[0025] The adjustable tire vulcanization preheating device of the present embodiment includes an air preheating box 1, and the air preheating box 1 is provided with a heat exchange tube group 18 connected with the outlet end of the superheated water pipeline in the vulcanizing machine; Including housing 11, pressure sensor 22 and temperature sensor 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com