Lipstick and preparation method thereof

A lipstick and mass percentage technology, applied in the field of lipstick and its preparation, can solve the problems of obvious makeup removal and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

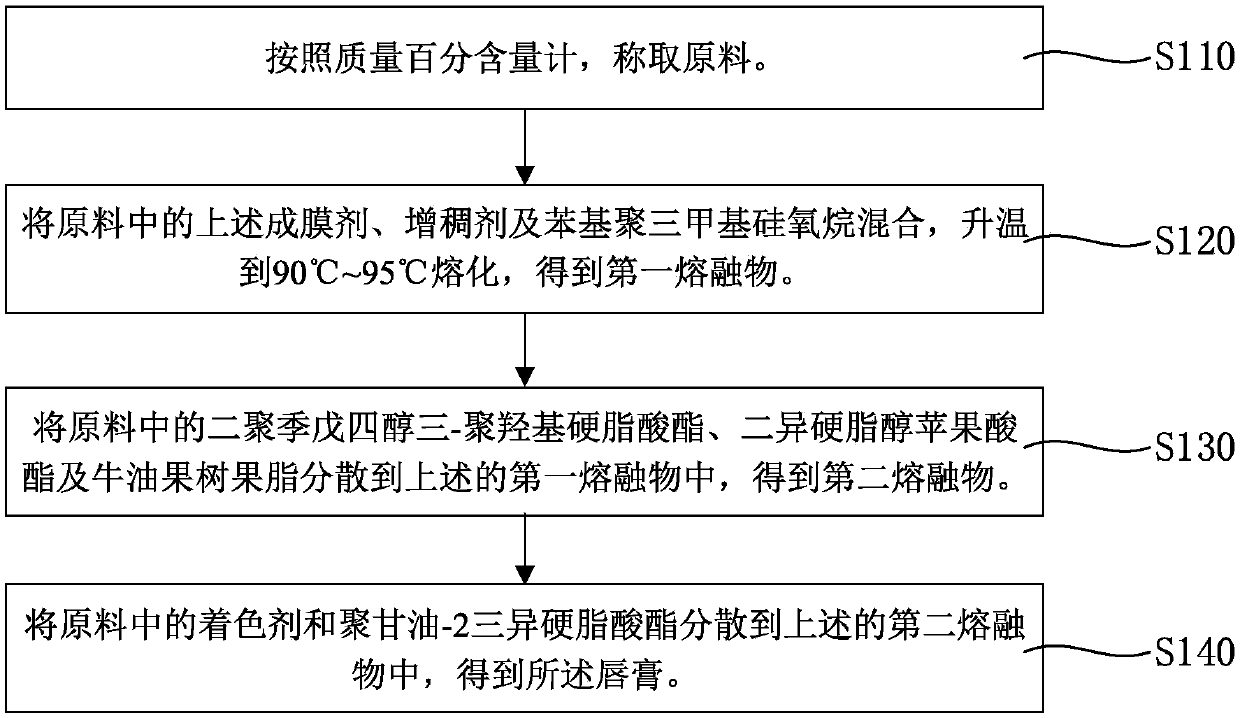

[0042] like figure 1 Shown, the preparation method of the lipstick of any one of the above-mentioned, comprises the steps:

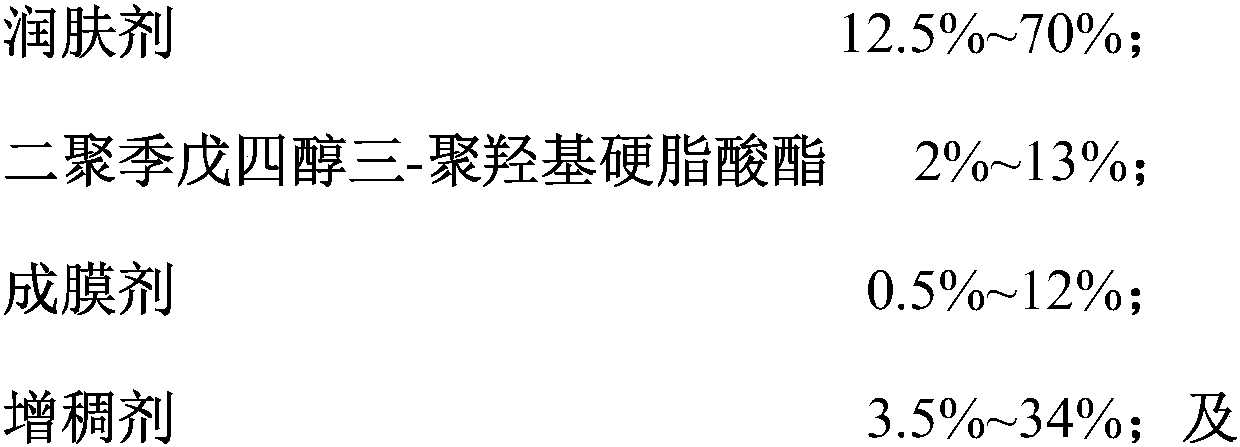

[0043] Step S110: In terms of mass percentage, weigh the following raw materials: emollient 12.5%-70%, dipentaerythritol tri-polyhydroxystearate 2%-13%, film-forming agent 0.5%-12%, 3.5% to 34% thickener and 5% to 21% colorant, wherein the above-mentioned emollients include phenyl polytrimethicone, diisostearyl malate, shea butter and polyester Glycerin-2 triisostearate, the content of the above-mentioned phenyl polytrimethicone accounts for 5% to 50% of the lipstick mass; the above-mentioned film-forming agent includes hydrogenated polycyclopentadiene, polyethylene, Brazil For palm wax and vitamins, the content of the above-mentioned hydrogenated polycyclopentadiene accounts for at least 80% of the mass of the above-mentioned film-forming agent.

[0044] It should be noted that, in some embodiments, some other additives need to be weighed in step S110...

Embodiment 1

[0060] The preparation steps of the lipstick of the present embodiment are as follows:

[0061] (1) In terms of mass percentage, the following raw materials were weighed: 5% phenyl polytrimethicone, 4.5% diisostearyl malate, 2% shea butter, 6% Polyglyceryl-2 triisostearate, 13% dipentaerythritol tri-polyhydroxystearate, 12% Koboguard HRPC, 12% ozokerite, 10% carnauba resin, 6% micro Crystal wax, 6% synthetic wax, 15% INBP45R7C, 6% TNP50T7-ATB, 0.5% tocopherol and 2% nylon 12.

[0062] (2) The above-mentioned Koboguard HRPC, ozokerite wax, carnauba resin, microcrystalline wax, synthetic wax and the above-mentioned phenyl polytrimethicone were mixed, heated to 90° C. and melted to obtain the first melt.

[0063] (3) The above-mentioned dipentaerythritol tri-polyhydroxystearate, diisostearyl malate, and the above-mentioned shea butter were dispersed in the above-mentioned first melt to obtain a second melt.

[0064] (4) Disperse the above-mentioned INBP45R7C, TNP50T7-ATB and po...

Embodiment 2

[0066] The preparation steps of the lipstick of the present embodiment are as follows:

[0067] (1) In terms of mass percentage, the following raw materials were weighed: 50% of phenyl trimethicone, 1% of diisostearyl malate, 10% of shea butter, 9% Polyglyceryl-2 triisostearate, 4% dipentaerythritol tri-polyhydroxystearate, 3.5% Koboguard HRPC, 1% ozokerite, 1% carnauba resin, 1% micro Crystal wax, 0.5% synthetic wax, 13% INBP45R7C, 6% TNP50T7-ATB.

[0068] (2) Mix the above-mentioned Koboguard HRPC, ozokerite wax, carnauba resin, microcrystalline wax, synthetic wax and the above-mentioned phenyl polytrimethicone, heat up to 95° C. and melt to obtain the first melt.

[0069] (3) The above-mentioned dipentaerythritol tri-polyhydroxystearate, diisostearyl malate, and the above-mentioned shea butter were dispersed in the above-mentioned first melt to obtain a second melt.

[0070] (4) Disperse the above-mentioned INBP45R7C, TNP50T7-ATB and polyglyceryl-2 triisostearate into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com