Reverse drilling matching repairing method of high-precision combined shell

A high-precision, shell technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve the problems of scrapping and loss of shell components, and achieve convenient clamping and processing and positioning accuracy High and prolong service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

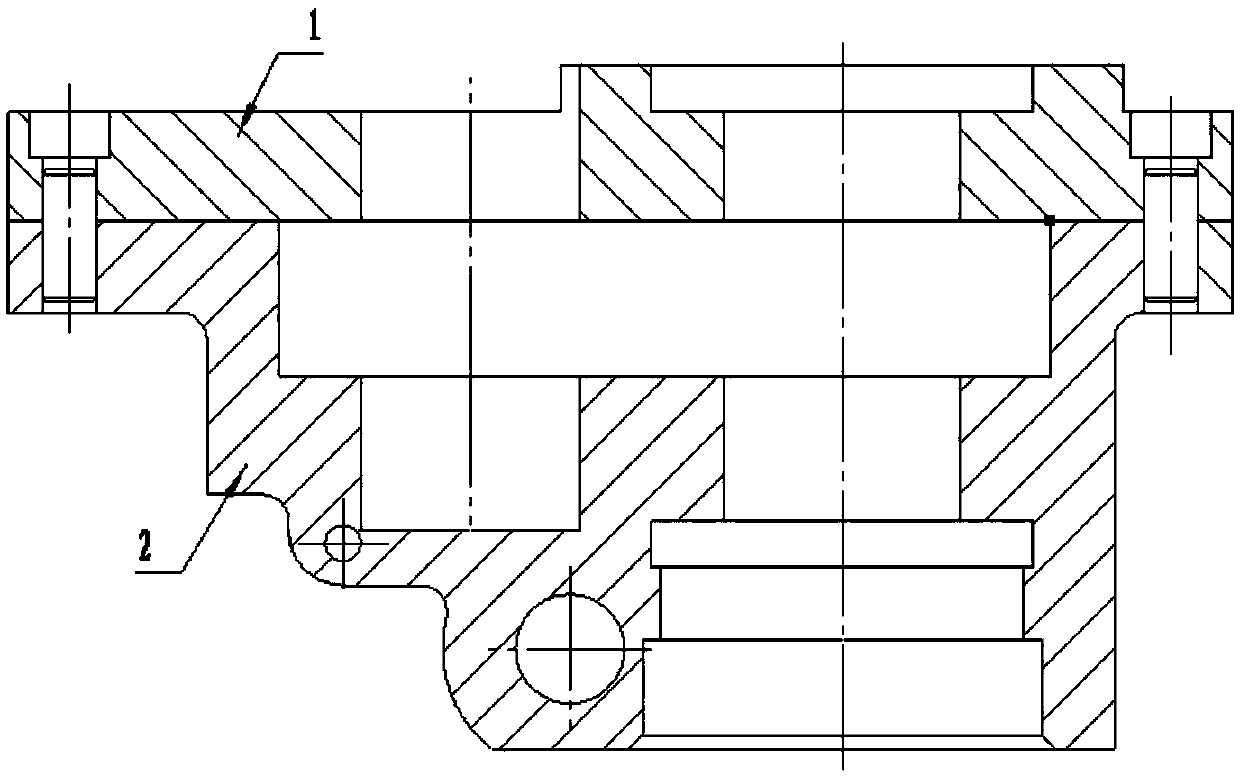

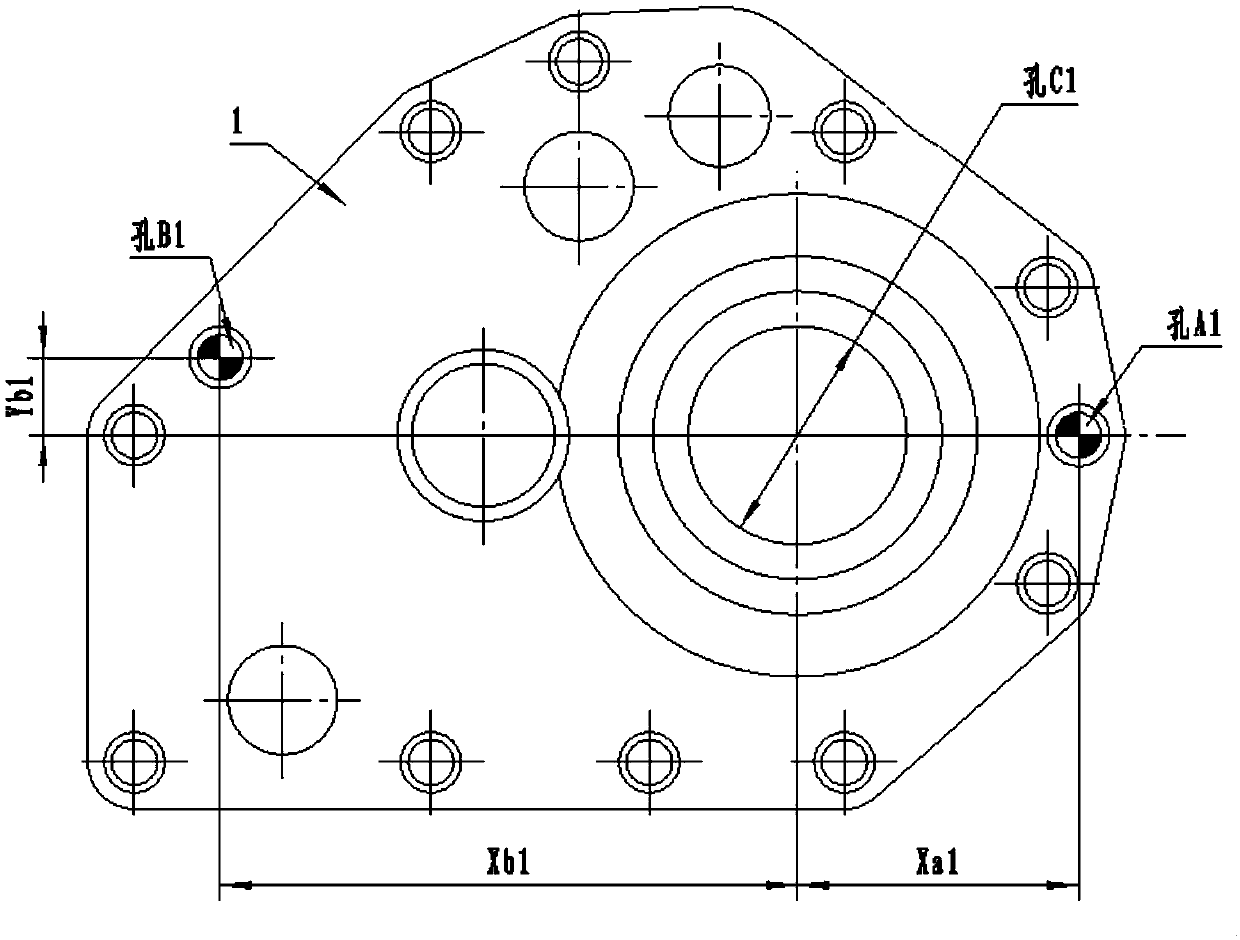

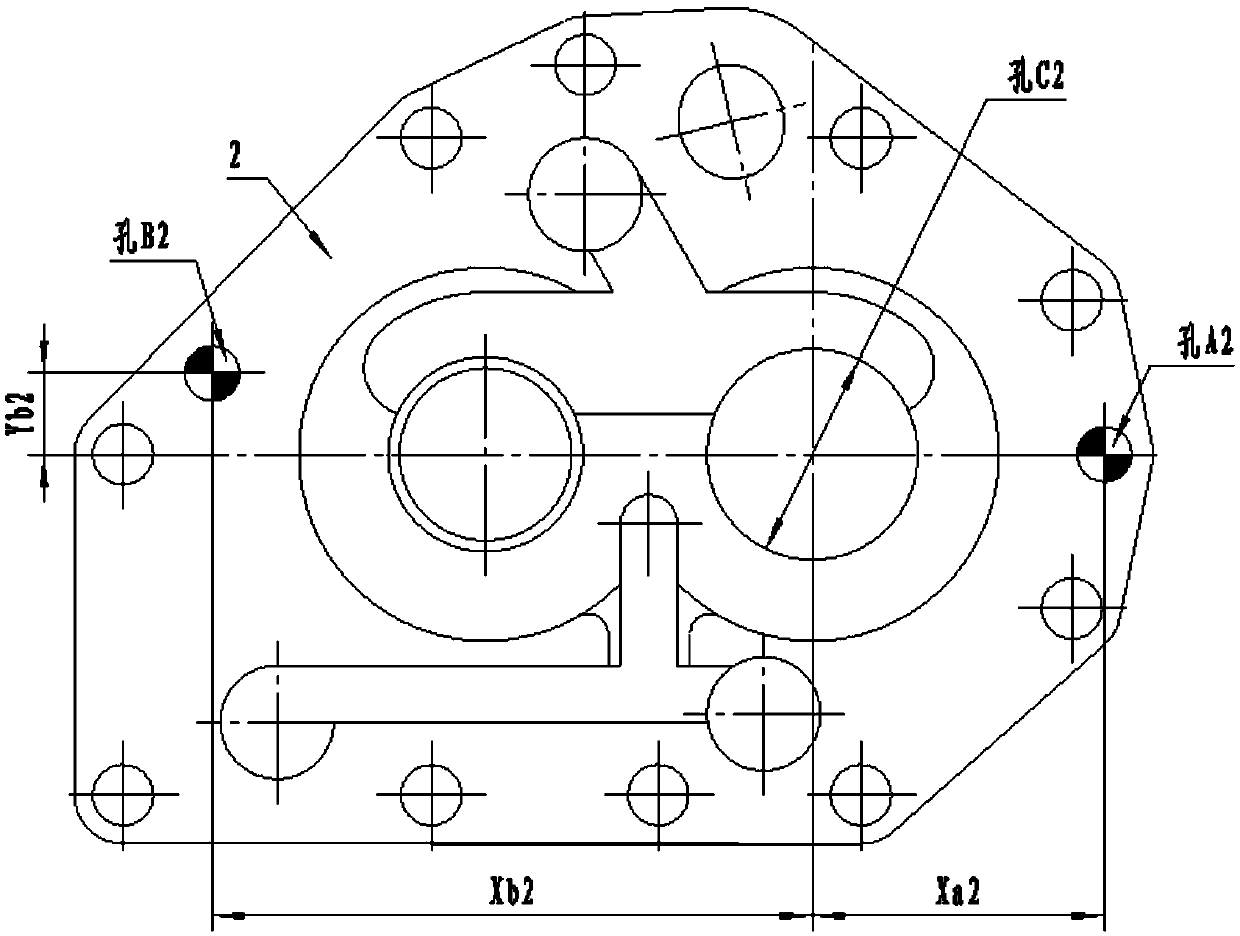

[0025] see figure 2 as well as image 3 , the present invention provides a method for repairing the reverse drill of a high-precision combined casing, the method for repairing the reverse drill of the high-precision composite casing includes the following steps:

[0026] 1) Determine the relative position of existing hole A1, hole B1 and matching hole C1 on the first complex shell; the first complex shell is an existing qualified shell, and its specific implementation method is:

[0027] 1.1) On the first complex shell, the matching hole C1 is used as the measurement zero point, and any hole in hole A1 and hole B1 is used as the measurement reference hole, and the measurement coordinate system is established by connecting the measurement zero point and the measurement reference hole;

[0028] 1.2) Measure the coordinates of hole A1 and hole B1 by a high-precision measuring instrument in the measurement coordinate system established in step 1.1), which are respectively (X A1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com