Polytetrafluoroethylene mold with heating function

A polytetrafluoroethylene and mold technology, applied in the field of polytetrafluoroethylene molds, can solve problems such as waste of resources, single mold, time increase, etc., and achieve the effects of convenient operation, reduced labor intensity, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

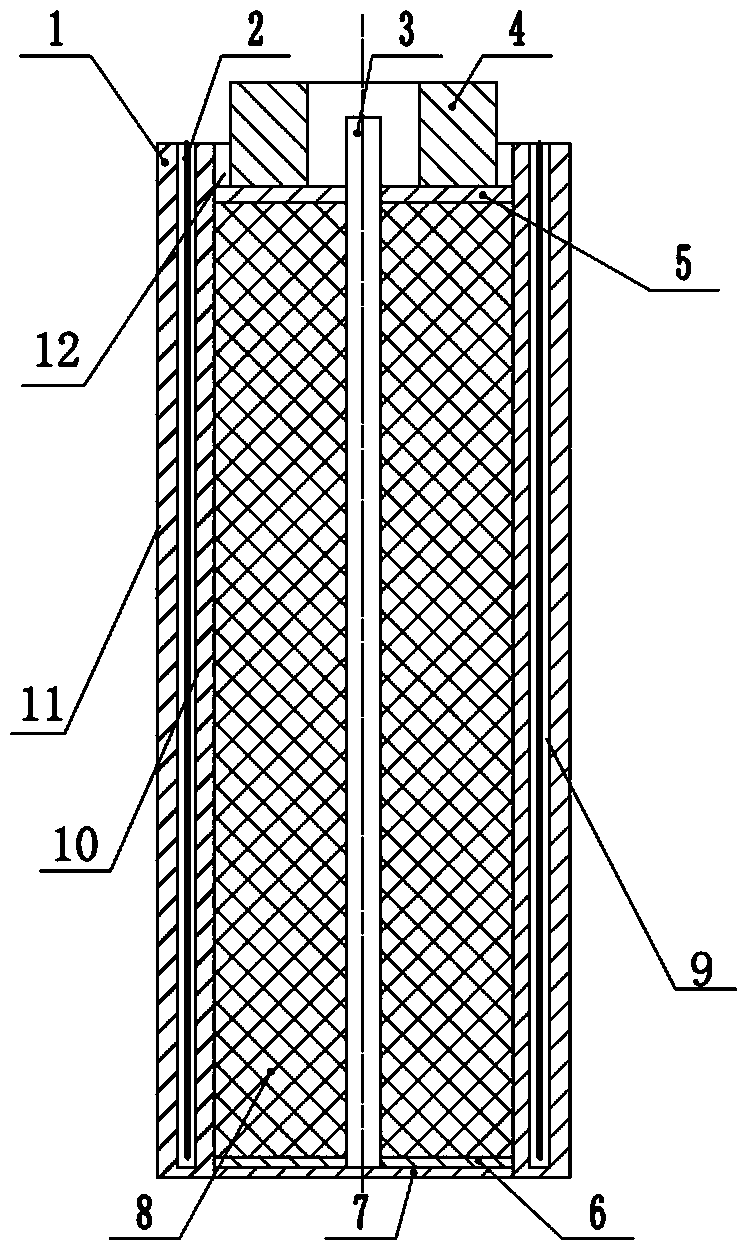

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 Shown, a kind of polytetrafluoroethylene mold with heating function described in the present invention, it comprises mold body 1, and described mold body 1 is elongated structure, and described mold body 1 inner bottom is provided with bottom plate 7, A blank chamber 8 is provided above the base plate 7, and a mandrel 3 is fixed to the base plate 7 in the blank chamber 8. An upper pressing plate 5 and a lower pressing plate 6 are respectively arranged in the blank chamber 8. The pressing plate 5 is also equipped with a pressing block 4 for extrusion, and the two sides of the mold body are respectively provided with heating grooves 9 for placing a heating device.

[0011] As shown in the figure, the inside of the heating tank 9 is provided with a heater 2 for heating the mold. The heater 2 is suspended in the middle of the tank body, and the length is 1CM from the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com