Residual heat recycling and reusing system for injection molding machine

A waste heat recovery and injection molding machine technology, which is applied in the field of injection molding machines, can solve the problems of injection molding machine loss, waste of resources, and non-management of heat, and achieve the effect of reducing heat dissipation pressure and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

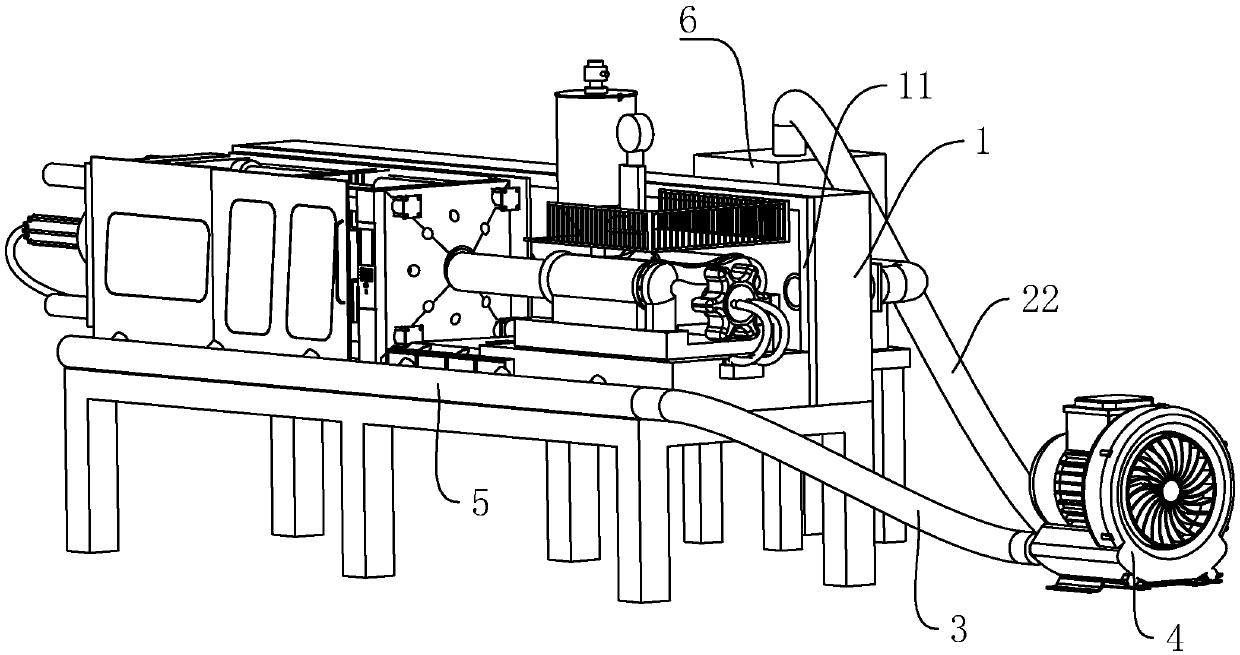

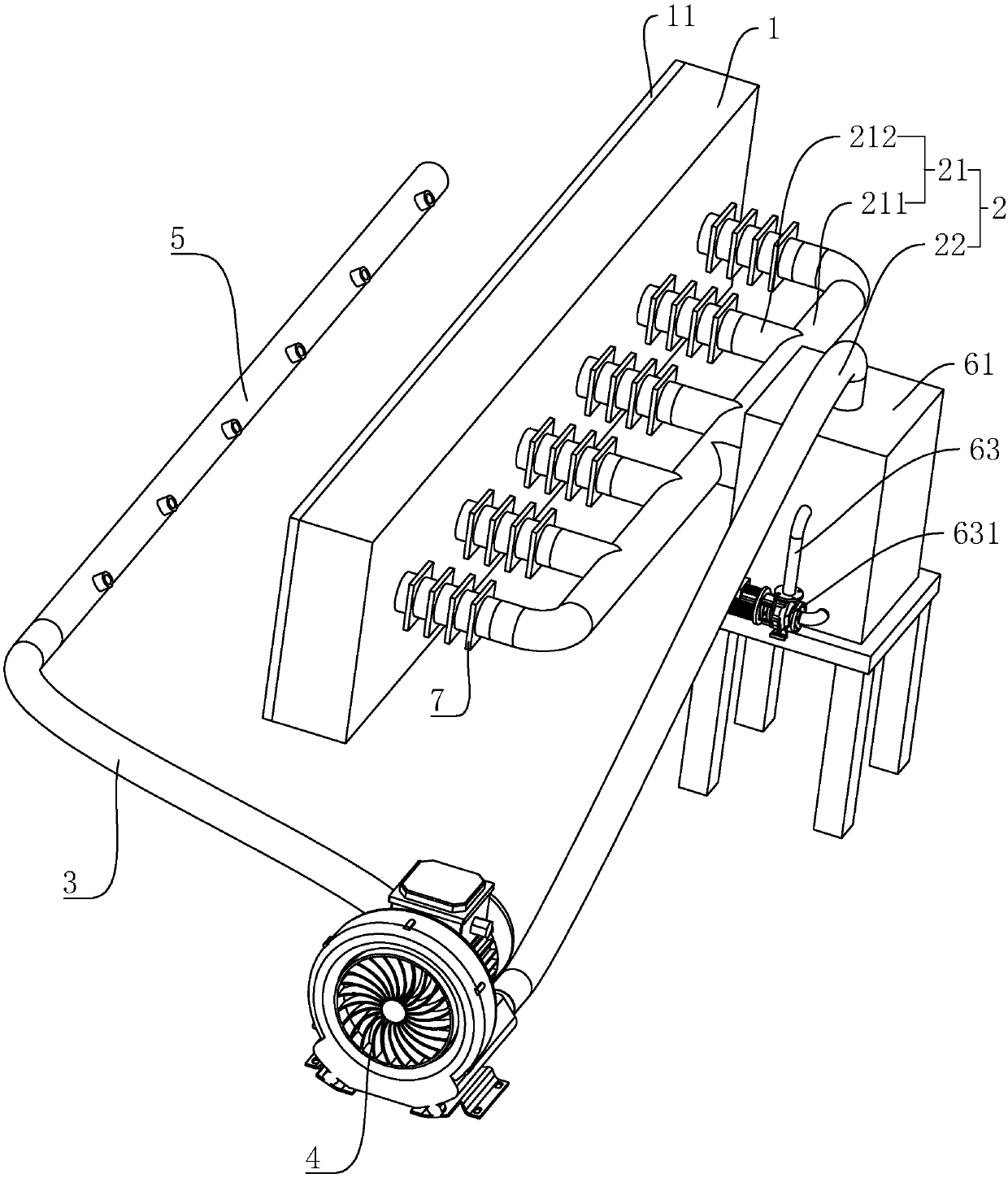

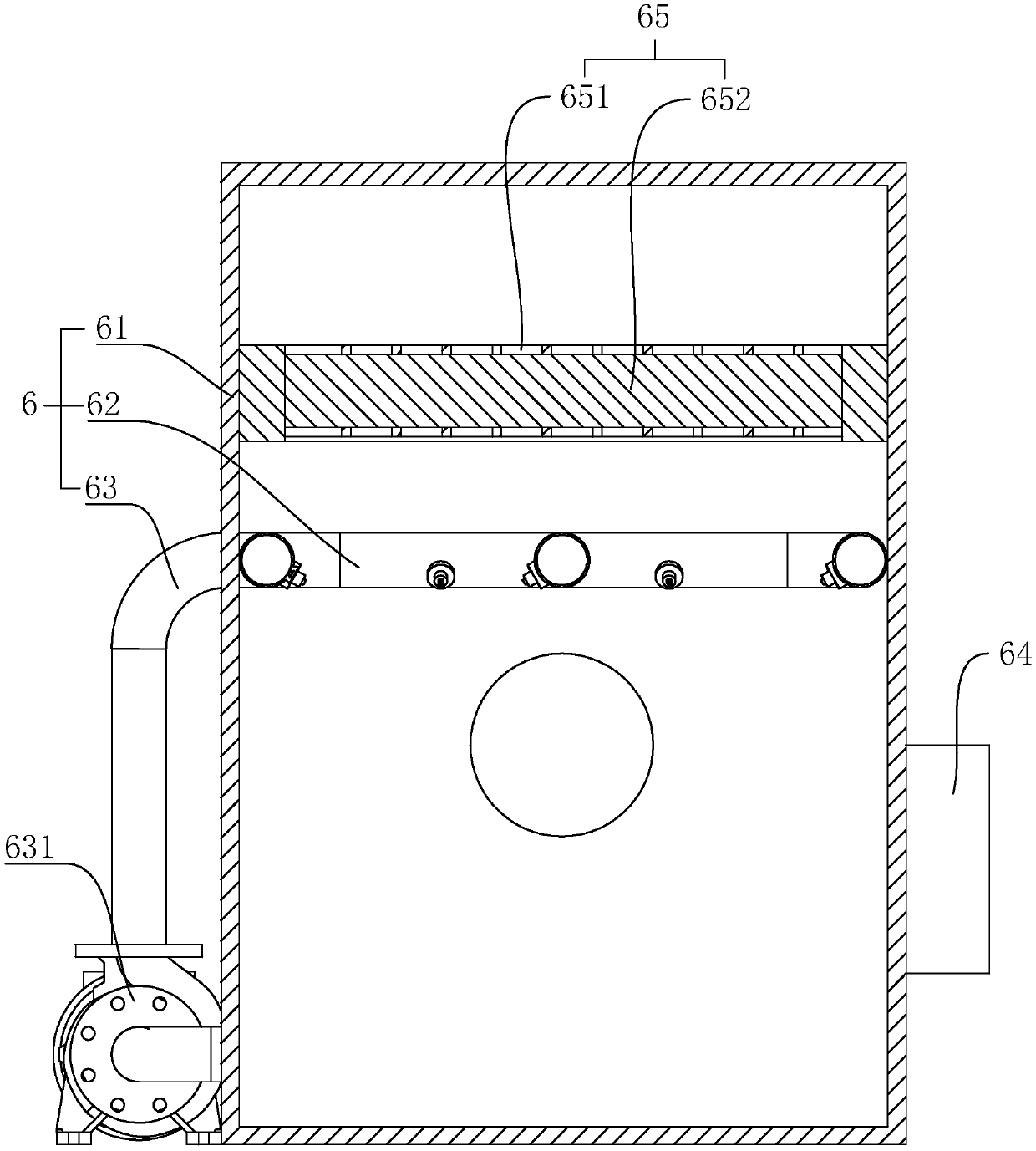

[0035] Embodiment: A waste heat recovery and reuse system for injection molding machines, refer to figure 1 , including heat collecting cover 1, heat collecting tube 2 (refer to figure 2 ), air pipe 3 and delivery fan 4. The heat collecting cover 1 is fixedly connected to one side of the operating table in the longitudinal direction, and is used for collecting heat from the injection molding machine. The heat receiving pipe 2 communicates with the heat collecting cover 1 for transporting heat from the heat collecting cover 1 . An air blowing pipe 5 is pierced on the side of the console opposite to the heat collecting cover 1, and an air blowing hole towards the injection molding machine is opened on the air blowing pipe 5. The air inlet of the conveying fan 4 is connected to the heat receiving pipe 2 , the air conveying pipe 3 is connected to the air outlet of the conveying fan 4 , and the air conveying pipe 3 is connected to the blowing pipe 5 . The heat receiving pipe 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com