Optical fiber coupling device and laser coupling equipment

A technology of optical fiber coupling device and coupling equipment, which is applied in the field of optical fiber coupling, and can solve the problems of inconvenient cleaning, limited use range, and easily damaged optical fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] This embodiment provides a laser coupling device, which includes a laser device, a laser shaper and a fiber coupling device. The laser device emits laser light that passes through the laser shaper and then inputs light into the input end of the fiber coupling device. The laser coupling device can be a semiconductor laser or others.

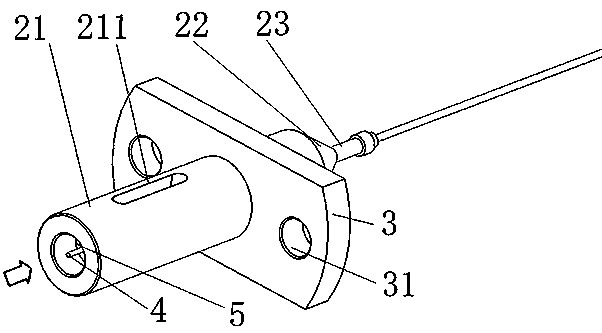

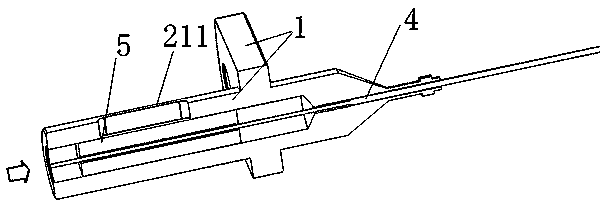

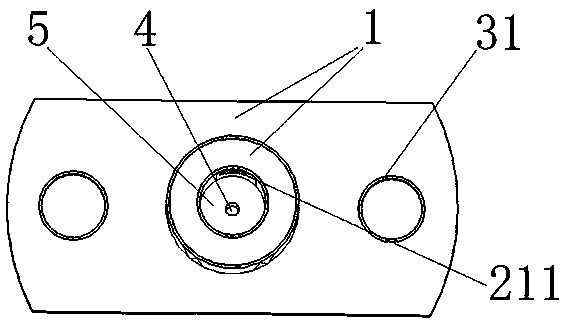

[0045] like Figure 1 to Figure 3 As shown, the fiber coupling device includes a heat-conducting housing 1 , a bare optical fiber 4 and a ferrule 5 . Among them, the bare optical fiber 4 is passed through the heat-conducting shell 1 for energy transmission; the ferrule 5 is located between the heat-conducting shell 1 and the bare optical fiber 4 to connect the heat-conducting shell 1 and the bare optical fiber 4, wherein the input of the ferrule 5 The ends are provided with reflective coatings. It should be noted that the input end of each component refers to the end of each component that is irradiated with light to input light.

[0046...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com