Automatic metering hopper

An automatic metering and hopper technology, applied in household components, household appliances, other household appliances, etc., can solve the problem that the hopper does not have a metering function, and achieve the effect of dynamic evaluation of the technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

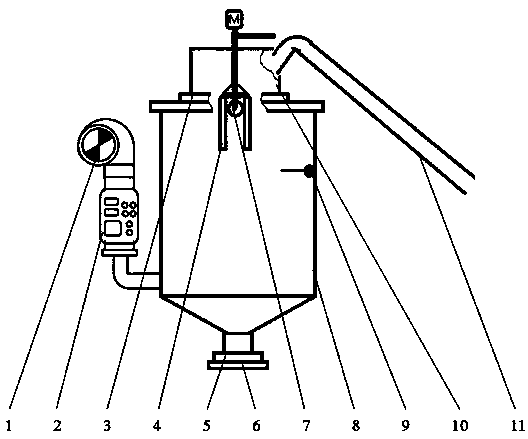

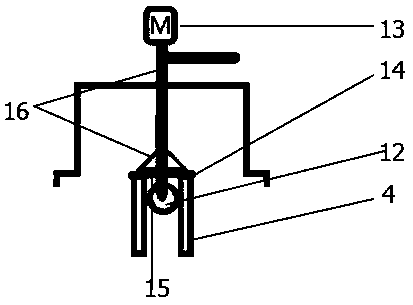

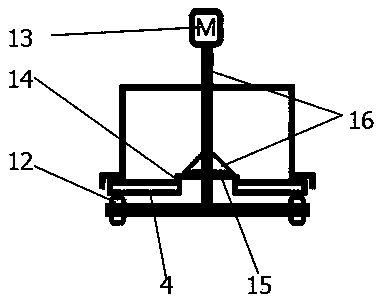

[0015] Such as figure 1 As shown, an automatic metering hopper is installed on the feed port of the plastic extruder through a support 6 . The hopper pressure sensing device 5 is installed between the bottom of the main hopper 8 and the support 6 . The hopper pressure sensing device 5 is a conventional known device that plays a weighing role similar to an electronic scale, and is mainly composed of a columnar pressure sensor, a data processing chip and a display screen. Hopper pressure sensing device 5 displays tare weight and net weight in real time. The plastic granules in the main hopper 8 fall into the feed port of the extruder along the pipeline by gravity. The weight of the main hopper 8 and all parts on it is applied to the columnar pressure sensor. The weight value weighed before feeding is the tare weight of the hopper, and the weight value weighed after feeding is subtracted from the tare weight of the hopper. The weight is the weight of the plastic.

[0016] The...

Embodiment 2

[0020] On the basis of embodiment 1, a data interface is added to the feed pressure sensing device 3 and the hopper pressure sensing device 5, and the cumulative feed quantity of the feed hopper 10 and the real-time material quantity in the main hopper 8 are two The data is transmitted to the production line computer.

[0021] When the production line is running, collect the real-time manufacturing length and material quota data of online products to calculate the rated material consumption, collect the accumulated feed quantity of the feed hopper 10 minus the real-time material quantity in the main hopper 8 and then subtract the material in the screw barrel of the extruder The actual material consumption is obtained after the empirical quantity, and the production status can be understood in real time by comparing the data of the actual material consumption and the rated material consumption. The operator can reset the collected and calculated data at any time. In this way, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com