Detachable camera support

A camera and cover technology, applied in bumpers, transportation and packaging, vehicle parts, etc., can solve the problems of cumbersome operation and high cost, and achieve the effect of reducing processing steps and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

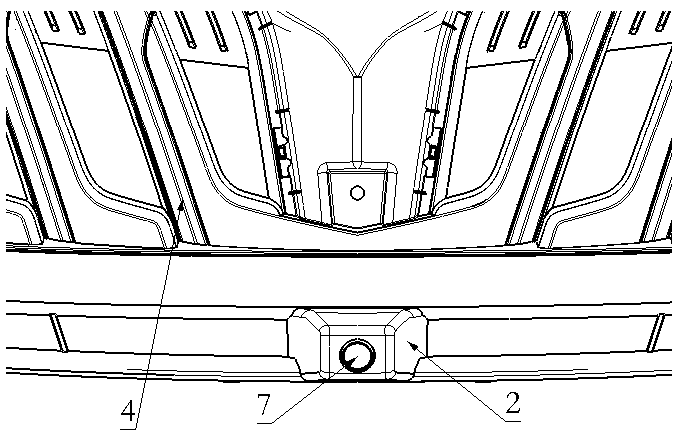

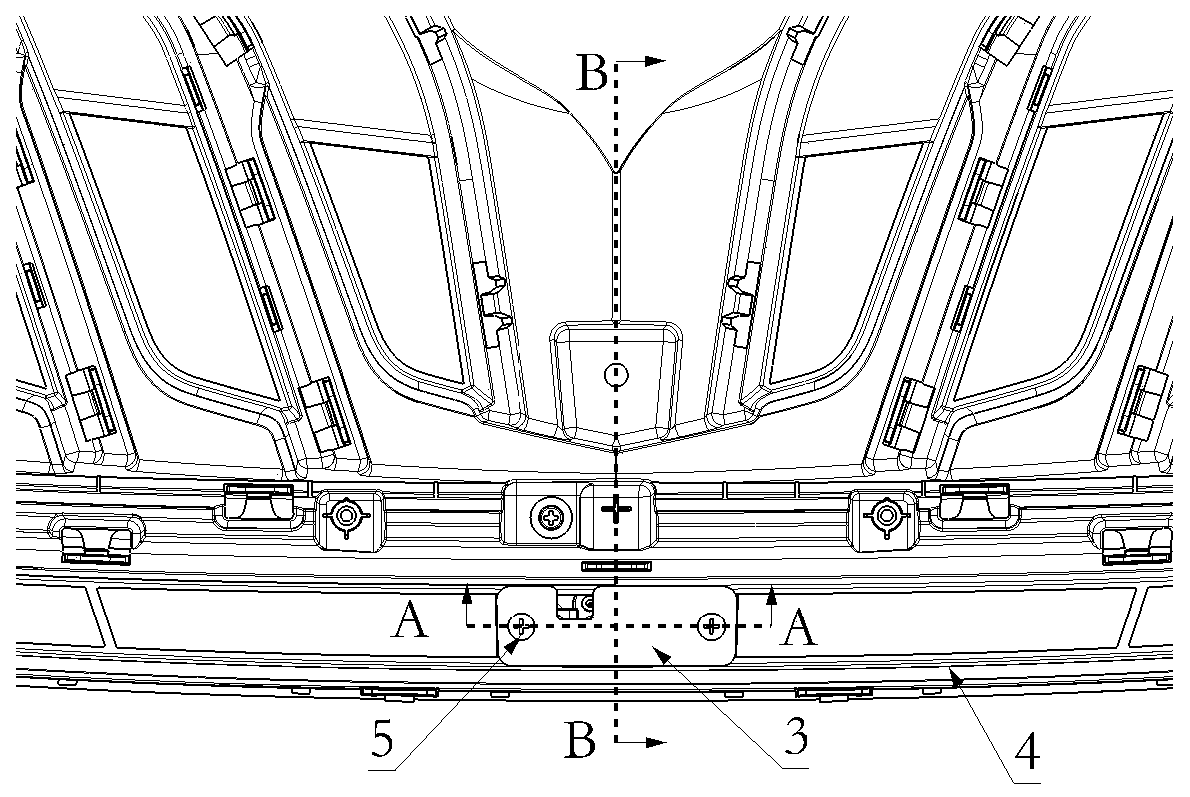

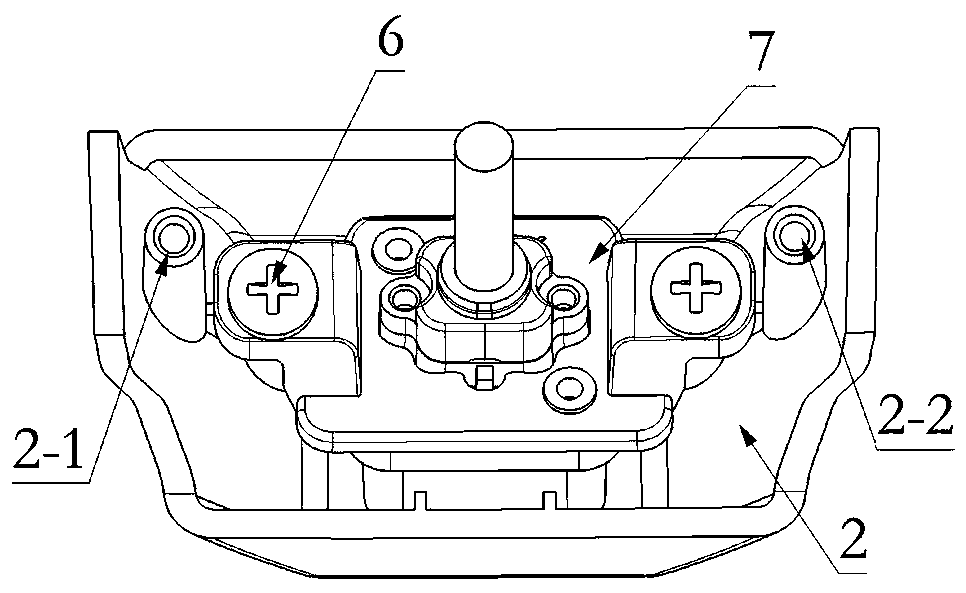

[0018] The detachable camera support 1 that present embodiment adopts comprises the support main body 2 with cover plate screw column 2-1 and 2-2, camera screw column 2-3 and 2-4, camera mounting hole 2-5 and belt There is a bracket cover plate 3 with a cover plate positioning groove 3-1, a stud positioning groove 3-2 and 3-3, and screw mounting holes 3-4 and 3-5. The camera 7 is installed in the camera installation hole 2-5 of the bracket main body 1, and the two camera screw posts 2-3 and 2-4 of the bracket main body 1 are respectively inserted into the camera positioning slots 7-1 and 7-2 and fixed by screws 6 , the cover screw columns 2-1 and 2-2 of the bracket main body 1 are respectively inserted into the stud positioning grooves 3-3 with screw mounting holes 3-5 on the bracket cover 3, and fixed by screws 5, the bracket cover The vertical rib 4-1 of front bumper 4 is plugged in the cover plate positioning groove 3-1 of 3, and support cover plate 3 is connected with fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com