Acid liquid filter device of stainless steel acid washing line

A filter device and pickling line technology, applied in the direction of filter circuit, filter separation, chemical instruments and methods, etc., can solve the problems of low efficiency of multi-stage sedimentation, large system footprint, short life of wearing parts, etc., and achieve cost Low, reduce work difficulty, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

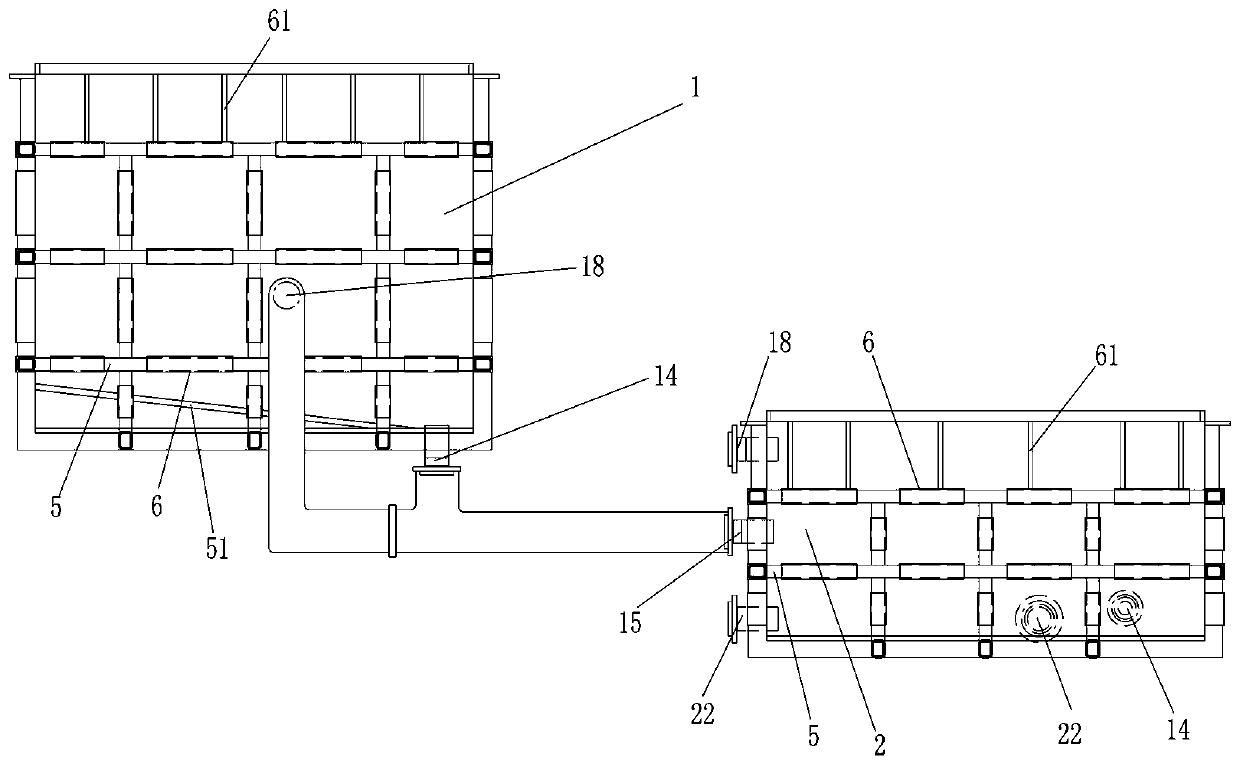

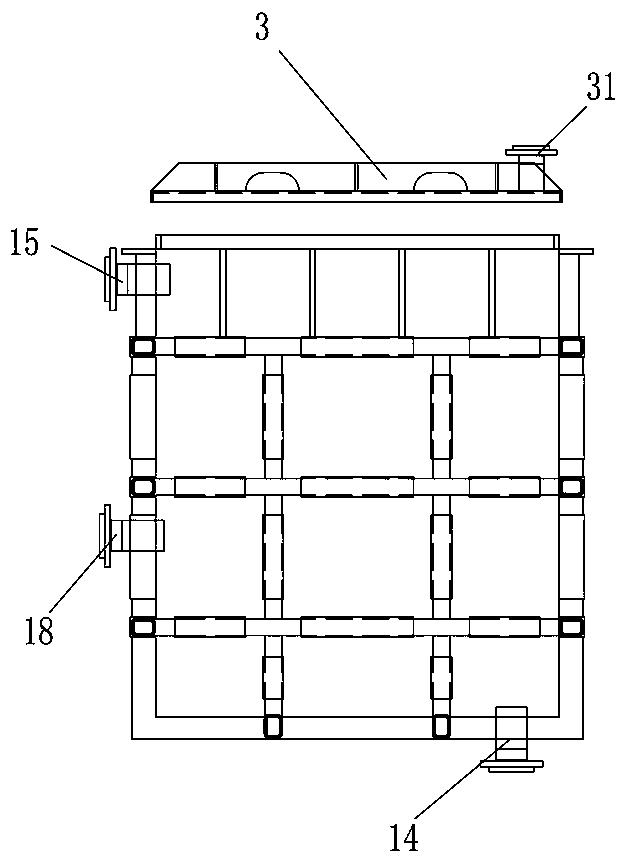

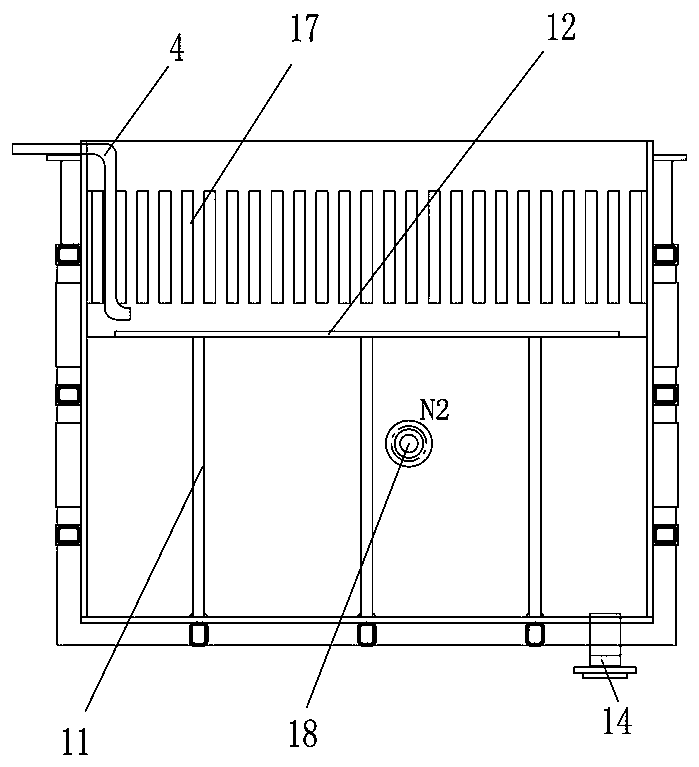

[0036] A stainless steel pickling line acid filter device, comprising a high-position desilter box 1 and a low-position filtrate box 2 connected through pipelines; The mud part includes a support member arranged in the mud removal box, a partition plate 12 with densely distributed filter holes arranged on the support member, and a filter plate 12 laid on the partition board and pulled up with its edge beyond the partition board. Cloth 13; the middle part of the filtrate tank is provided with an overflow baffle 21 for separating the inside of the filtrate tank into two cavities of liquid inlet and liquid outlet, and the top of the overflow baffle is lower than the height of the mouth of the filtrate tank, The acid inlet of the filtrate box is located at the liquid inlet, and the acid outlet is located at the outlet chamber; the bottom of the desilter box is provided with an acid outlet 14, and the top is provided with an acid inlet 15, and the inlet of the filtrate box The acid...

Embodiment 2

[0040] The difference from the above embodiment is that the support includes a lattice shelf 11 formed by intersecting a plurality of vertical shelves and forming a lattice, and a hole for acid liquid to circulate in the entire box body opened at the bottom of the lattice shelf. Circulation notch 111, the bottom end of the grid frame is connected to the bottom of the box body, the side edge of the grid frame is connected to the inner wall of the box body, and the partition is arranged on the grid frame.

[0041] The iron scale is relatively heavy, and generally 1.5 to 2 tons of iron scale are removed at one time. The length, width and height of the box body have reached one to two meters. In this embodiment, the length, width and height of the desilting box are 2 meters and 1.44 meters respectively. , 1.75 meters, and the length, width and height of the filtrate tank are 3 meters, 1.2 meters, and 1.1 meters. It is impossible to support the weight of a large amount of oxidized ...

Embodiment 3

[0045] The difference from the above embodiment is that the acid inlet of the desilter box is set on the desilter part, and the acid outlet of the desilter box is set on the side of the box body opposite to the acid inlet. At the bottom of one side, on the same side as the acid inlet, the tank body is provided with a purge pipe 4 for passing high-pressure gas into the acid liquid, and the purge pipe goes deep into the tank from the top of the tank body. In the main body, the acid liquid flow part is provided with an overflow port 18 which communicates with the acid inlet port of the filtrate tank through a pipeline. In this application, through the setting of the purge pipe, high-pressure air is continuously blown to the acid liquid in the desilting part, so that the acid liquid flows, and at the same time, the iron oxide scale in the filter bag is stirred to improve the filtration efficiency, speed up the filtration, and prevent sedimentation and clogging.

[0046] The acid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com