Jacking and reinforcing method for buckling reinforced concrete column

A reinforced concrete column and jacking technology, applied in the directions of columns, piers, pillars, etc., can solve the problems of poor design, improper construction, increased construction costs, etc., and achieve reliable reinforcement effect, simple construction technology, and economical repair. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further explained below.

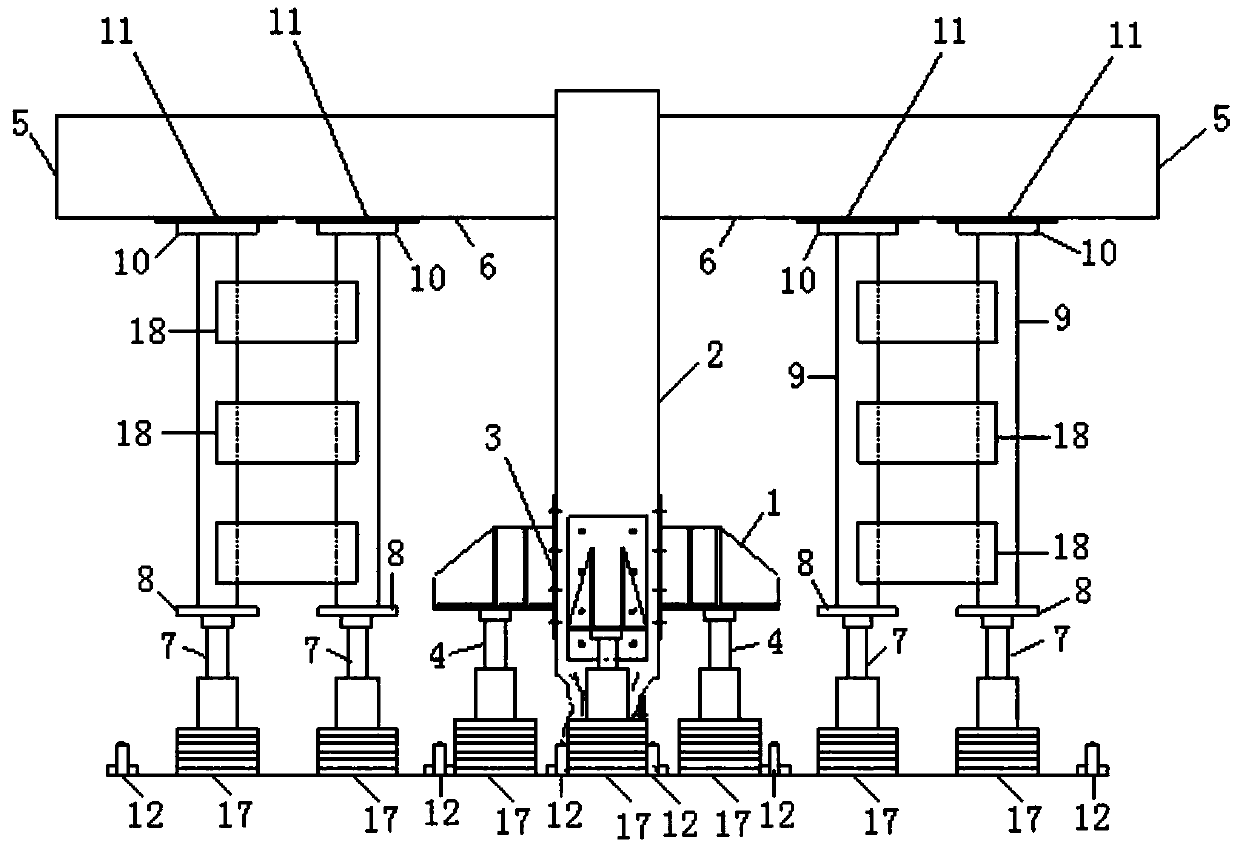

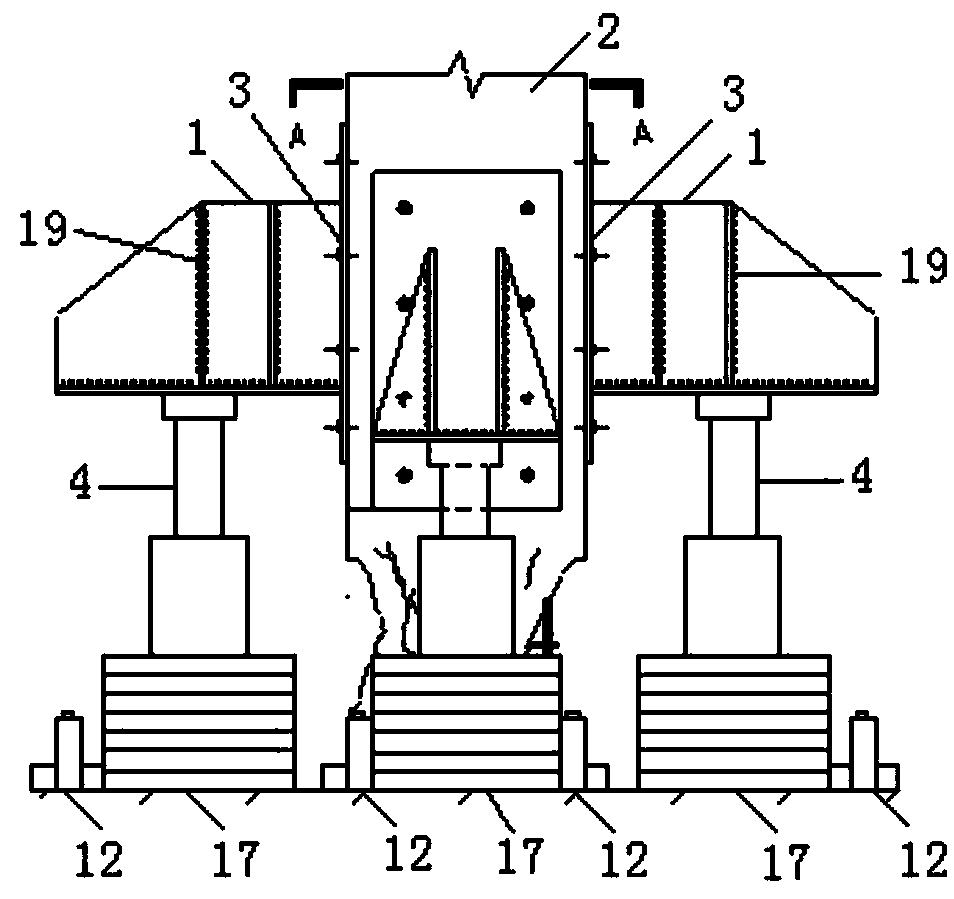

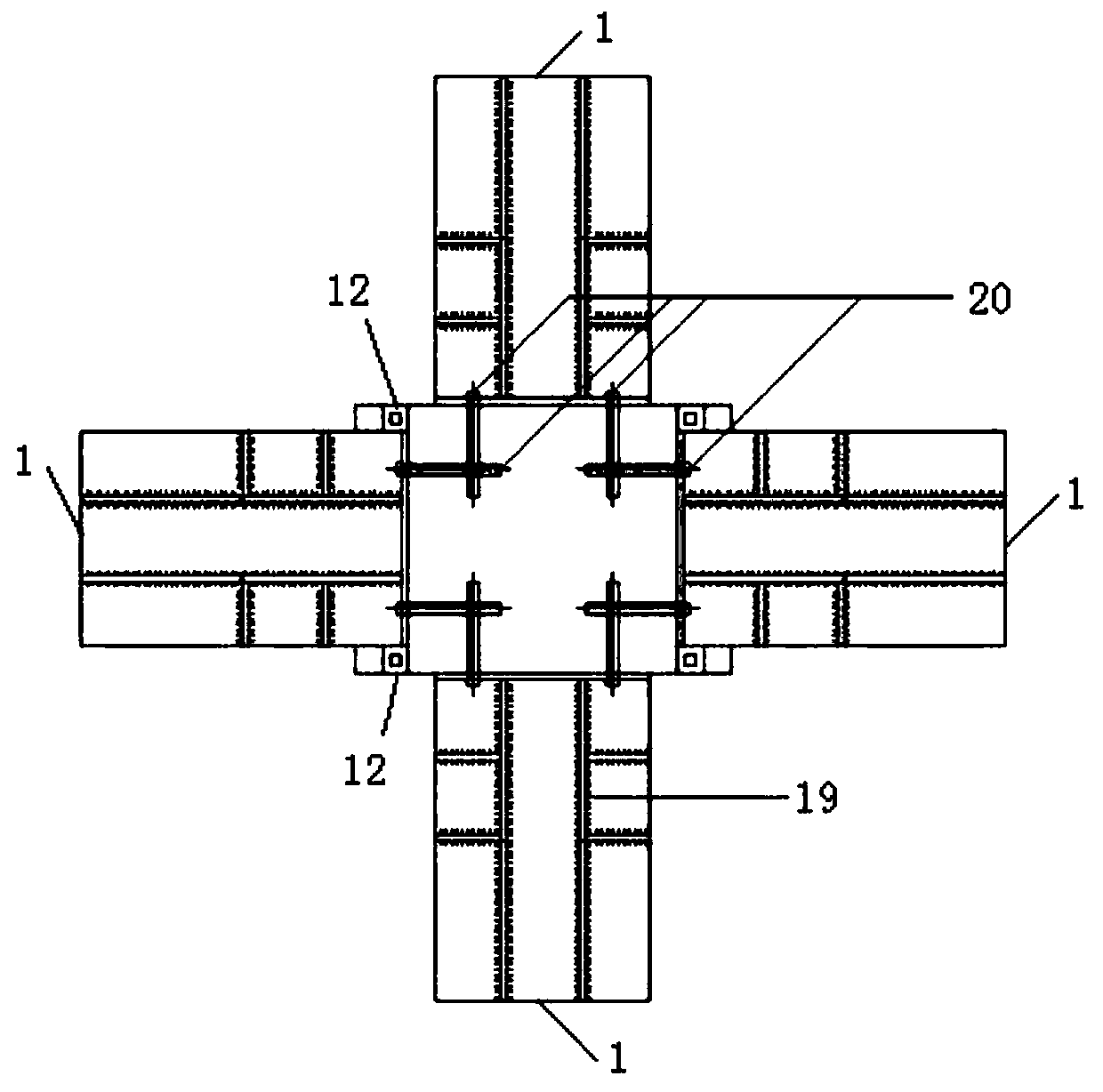

[0047] Such as Figure 1 to Figure 6 As shown, a method for jacking-up and strengthening of a buckling reinforced concrete column includes the following steps:

[0048] Step one, making steel corbel 1:

[0049] Make a steel corbel 1 that matches the longitudinal section width of the compression-buckled reinforced concrete column 2 that needs to be reinforced. The steel corbel 1 has a steel corbel connecting plate 3 that is connected to the compression-buckled reinforced concrete column 2 and a steel corbel connecting plate A number of bolt holes are reserved on 3; the width of the steel corbel connecting plate 3 is not greater than the width of the longitudinal section of the buckled reinforced concrete column 2.

[0050] Step two, install steel corbel 1 and jacking device:

[0051] 150mm~200mm above the crushing area of the buckled reinforced concrete column 2 is used as the sticking position of the lower edge of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com