High-pressure integrated pump

A technology of high-pressure integration and pump casing, which is applied in the direction of pumps, pump components, variable displacement pump components, etc., to achieve the effect of balancing oil pressure and pressure equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

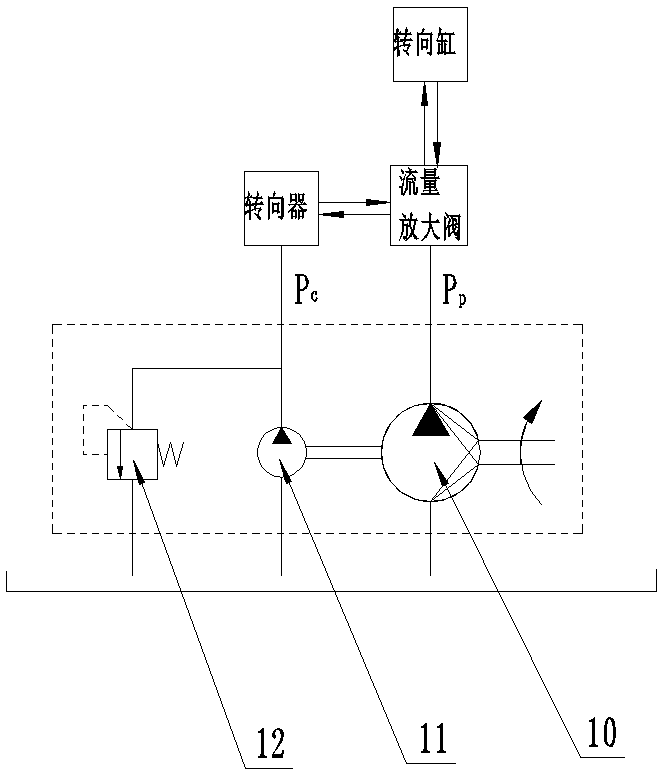

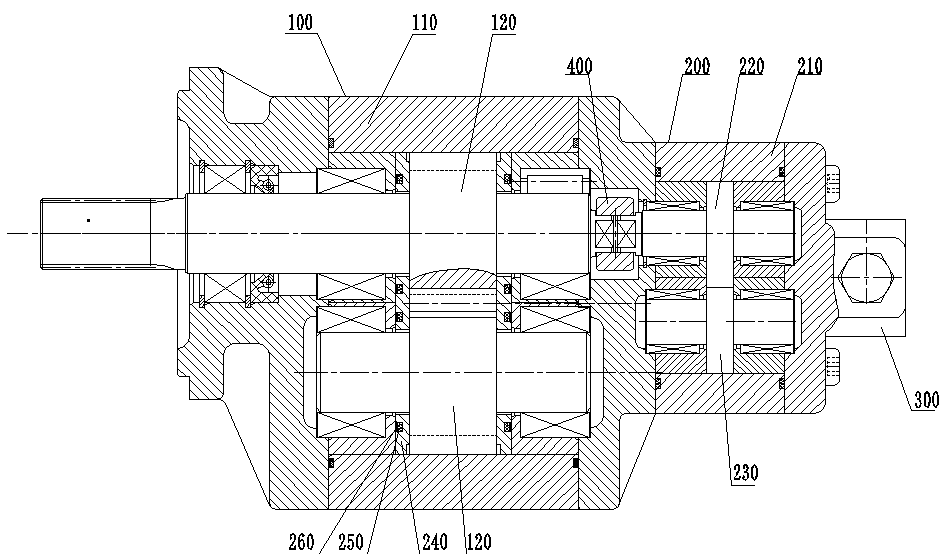

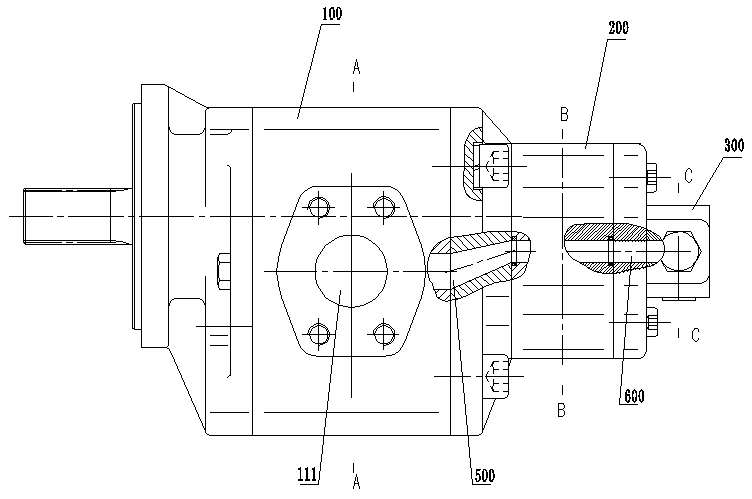

[0049] Specific implementation method: when working, the oil in the external oil tank flows into the low-pressure area of the first pump casing through the oil inlet of the steering pump, and then flows into the low-pressure area of the pilot pump through channel A. When the first driving gear rotates, it will simultaneously Drive the first driven gear and the second driving gear to rotate, and the rotation of the second driving gear will drive the rotation of the second driven gear. During the rotation process of the first driving gear and the first driven gear, the low pressure area of the steering pump will be The oil is transported to the high-pressure area and flows out from the first oil outlet. During the rotation of the second driving gear and the second driven gear, the oil in the low-pressure area of the pilot pump will be transported to the high-pressure area and flow out from the oil passage B. It flows into the relief valve, and then flows out from the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com