Engine lubricating oil supply system

An oil supply system and engine technology, which is applied in the direction of engine lubrication, engine components, turbine/propulsion lubrication, etc., can solve problems such as the oil supply system not working properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

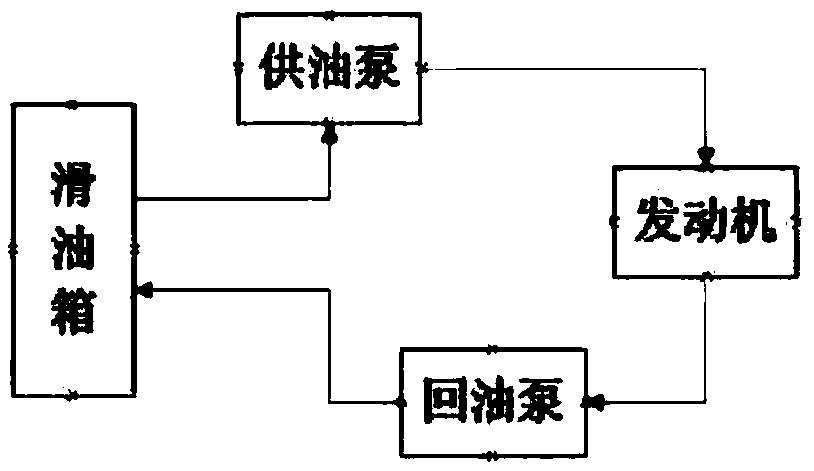

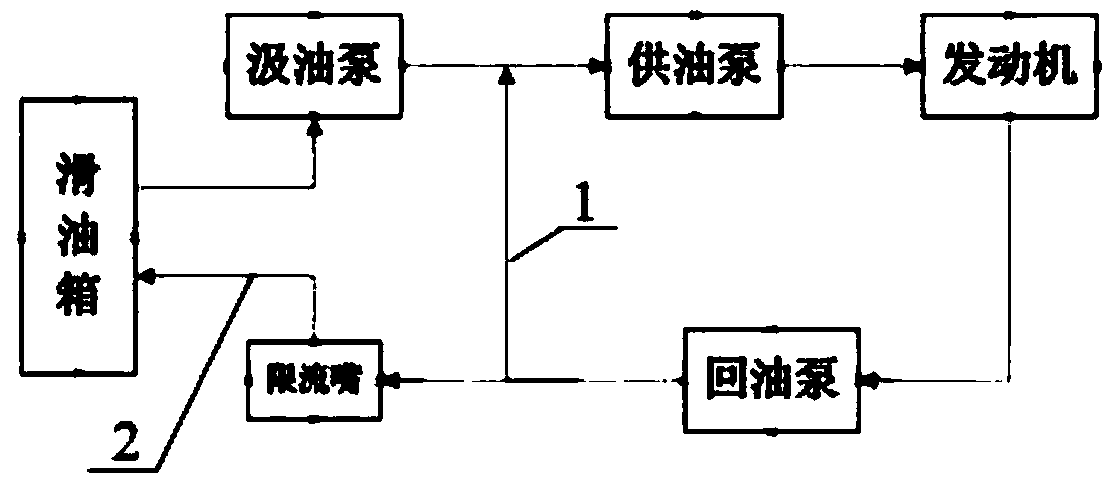

[0015] Such as figure 2 As shown, an engine lubricating oil supply system of the present invention is characterized in that it includes a lubricating oil tank, an oil supply pump and an oil return pump, and is characterized in that it also includes an oil pump, which is arranged in front of the oil supply pump. The flow rate of the oil pump is 50% of the oil supply pump, the lubricating oil in the lubricating oil tank is supplied to the engine after being pressurized by the oil pump and the oil supply pump. After lubricating and cooling the gears and bearings, it is pumped back by the oil return pump. Part of the return oil of the engine enters the oil supply pump along the first flow path 1 and continues to circulate, and part of it flows back to the lubricating oil tank along the second flow path 2. Adjust the restrictor on the top to ensure that the flow of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com