Adaptor for transporting transported goods and method for cleaning adaptor

A technology for conveying materials and adapters, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc. It can solve problems such as error-prone, and achieve the effect of reducing the risk of hole forming and reducing the risk of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

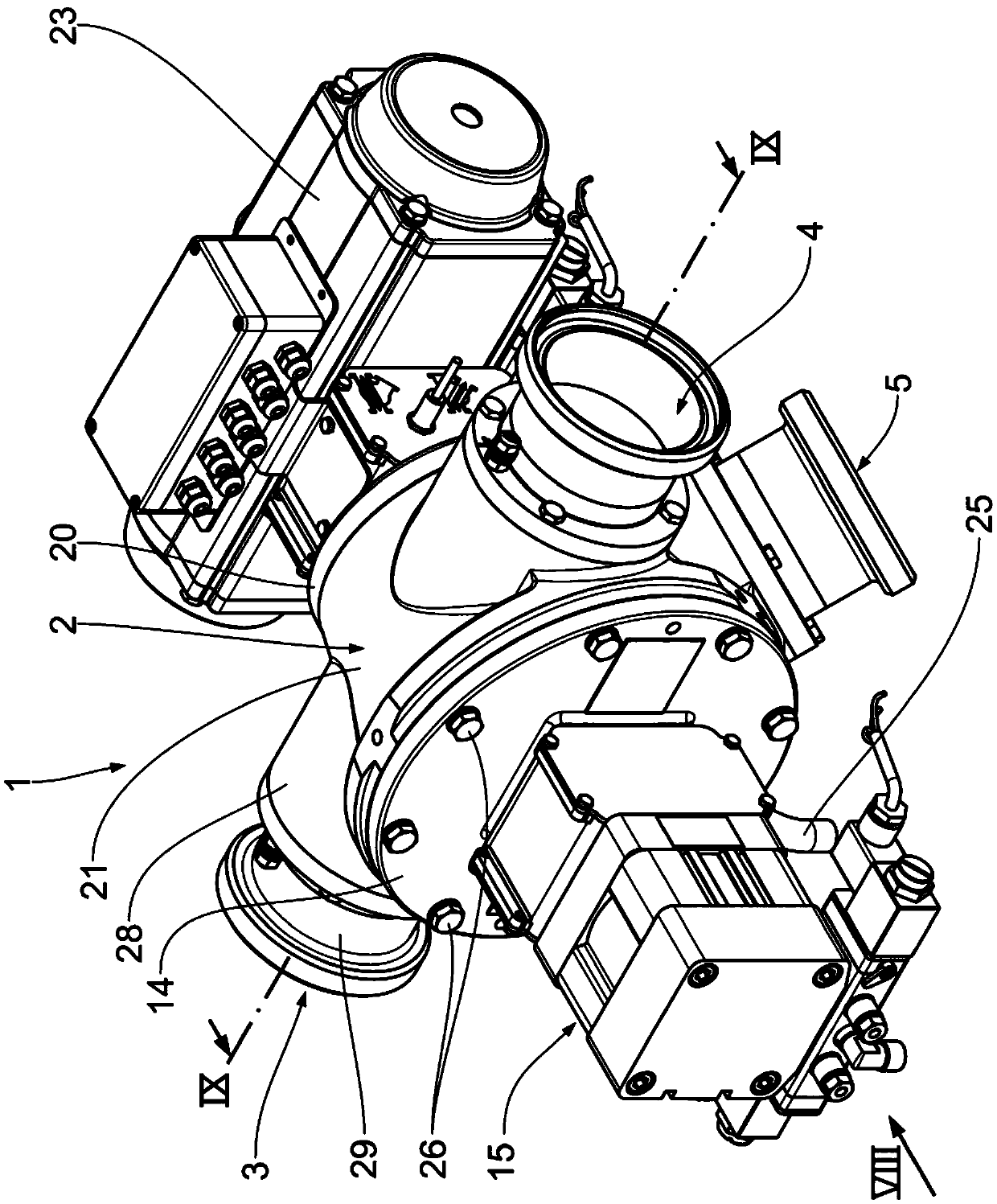

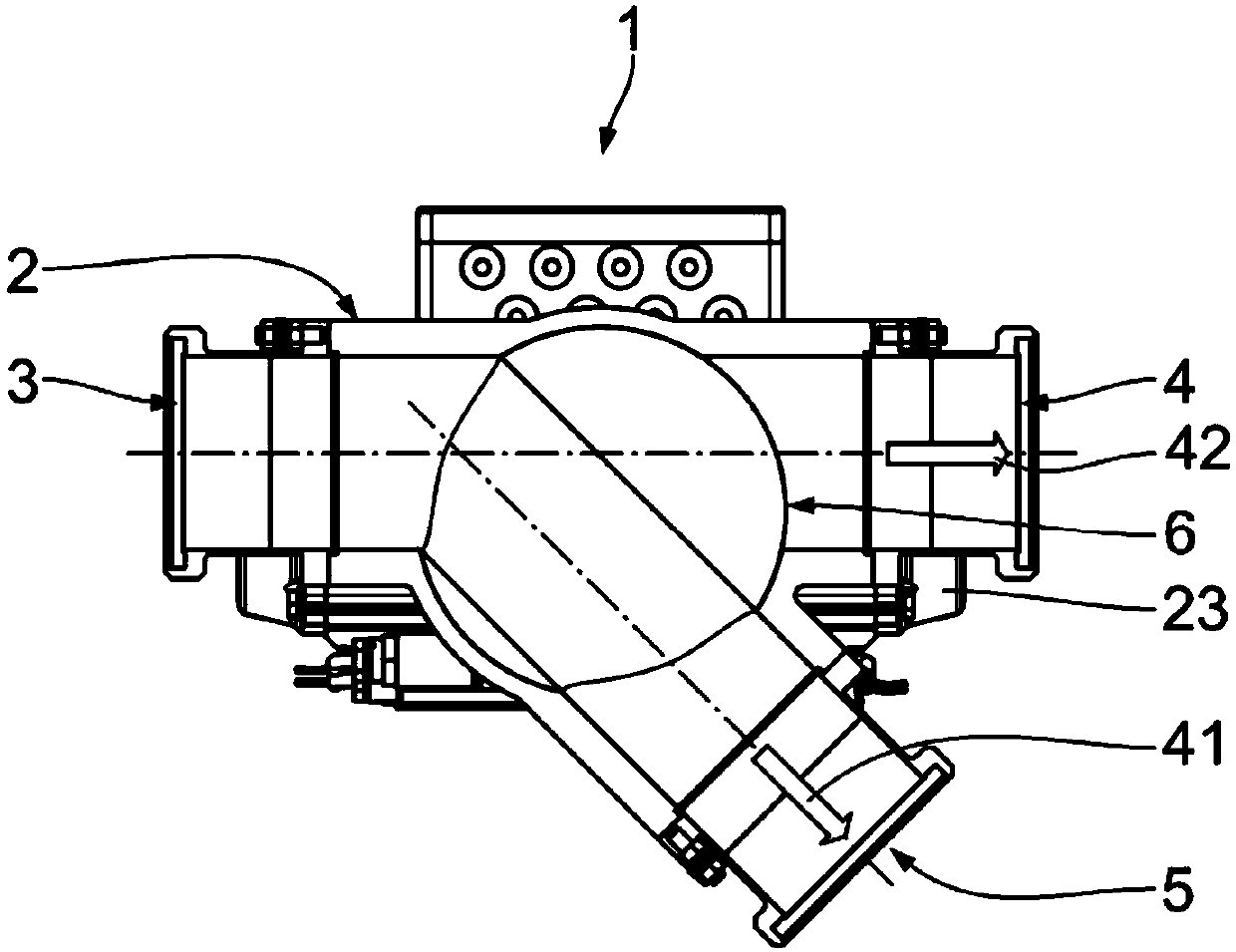

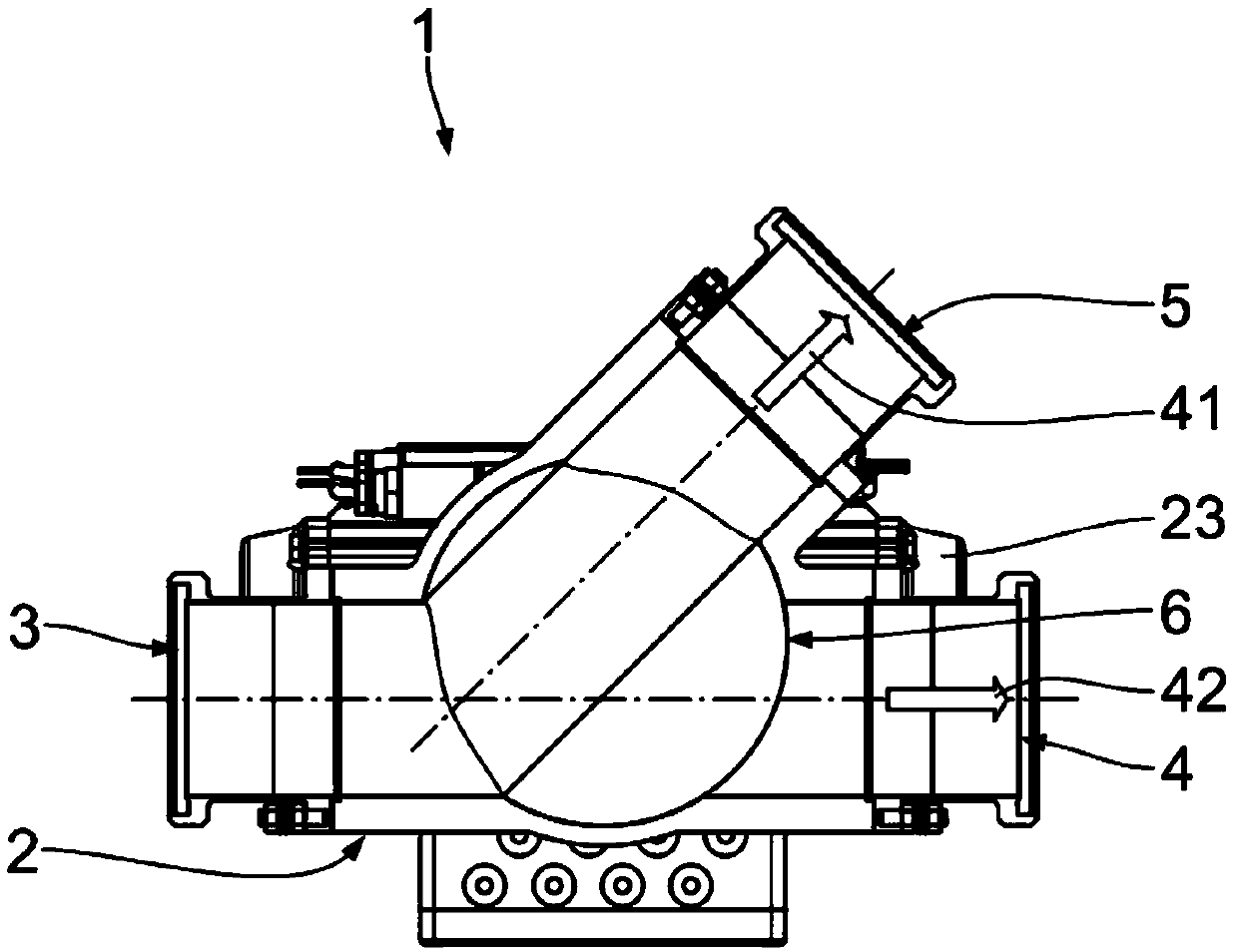

[0083] Figure 1 to Figure 12 The adapter 1 shown in is used for conveying the conveyed material. The conveyed material is, for example, bulk material, in particular granular and / or powdery material, such as plastic granules or granular and / or powdery food. Especially for the pneumatic conveying of bulk materials. The conveyed material can also be pasty substances and / or liquids, ie fluids.

[0084] The adapter 1 is embodied as a three-way adapter. The adapter 1 has a housing 2 on which a first through-opening 3 , a second through-opening 4 and a third through-opening 5 are arranged. Through openings 3 , 4 , 5 are used for supplying and / or discharging conveyed material. The through openings 3 , 4 , 5 , in particular the center lines of the through openings 3 , 4 , 5 define the conveying plane.

[0085] A rotary part 6 is arranged in the housing 2 . The rotary part 6 has an axis of rotation 7 , which is oriented perpendicular to the conveying plane. The rotary part 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com