Electrostatic purifying device and kitchen ventilator with same

A purification device and electrostatic technology, which is applied in the field of range hoods, can solve the problems of easy conduction of positive and negative plates, failure of electrostatic purification devices, and inability to operate, so as to achieve convenient after-sales maintenance, maintain long-term cleanliness, and reduce oil fume emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

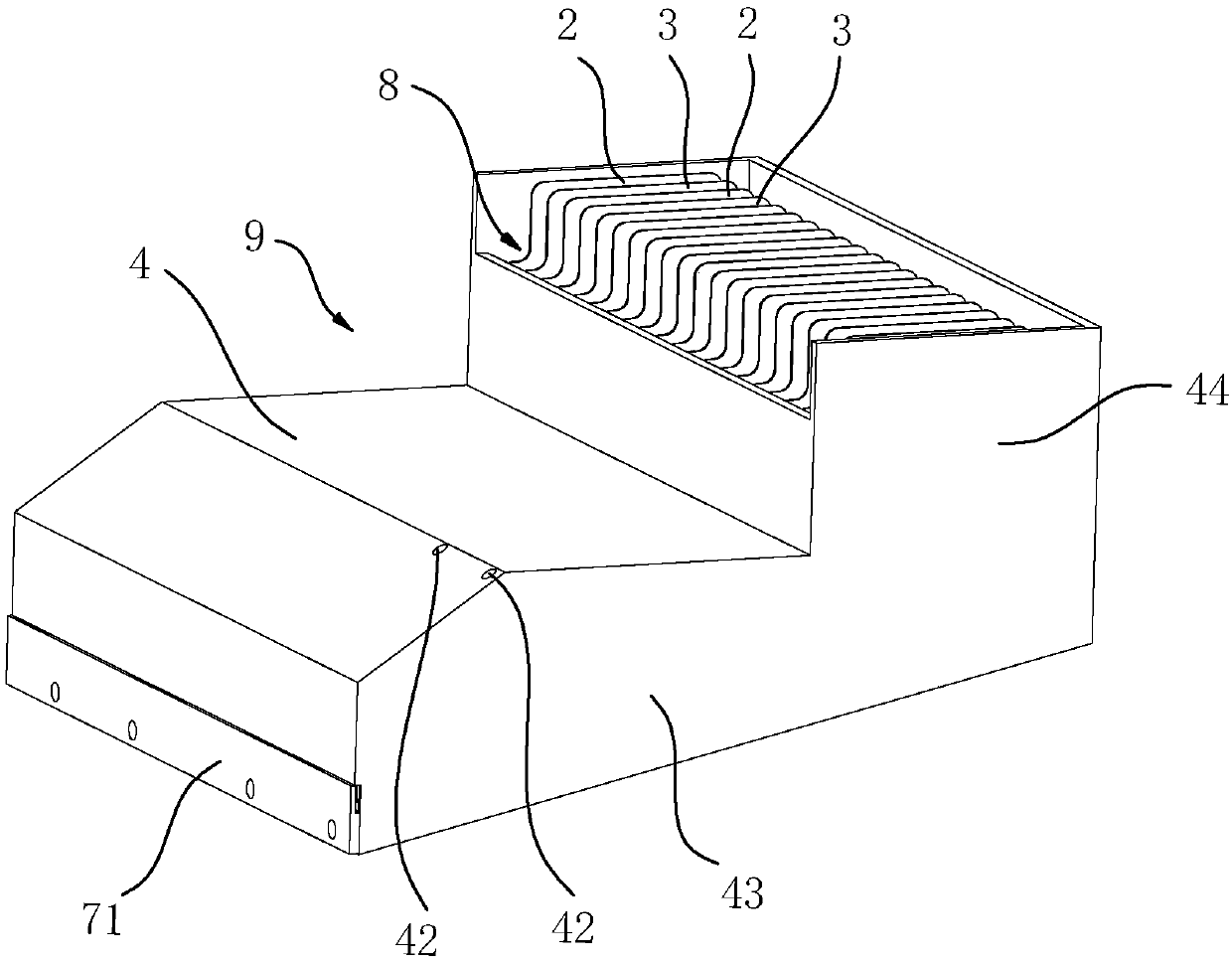

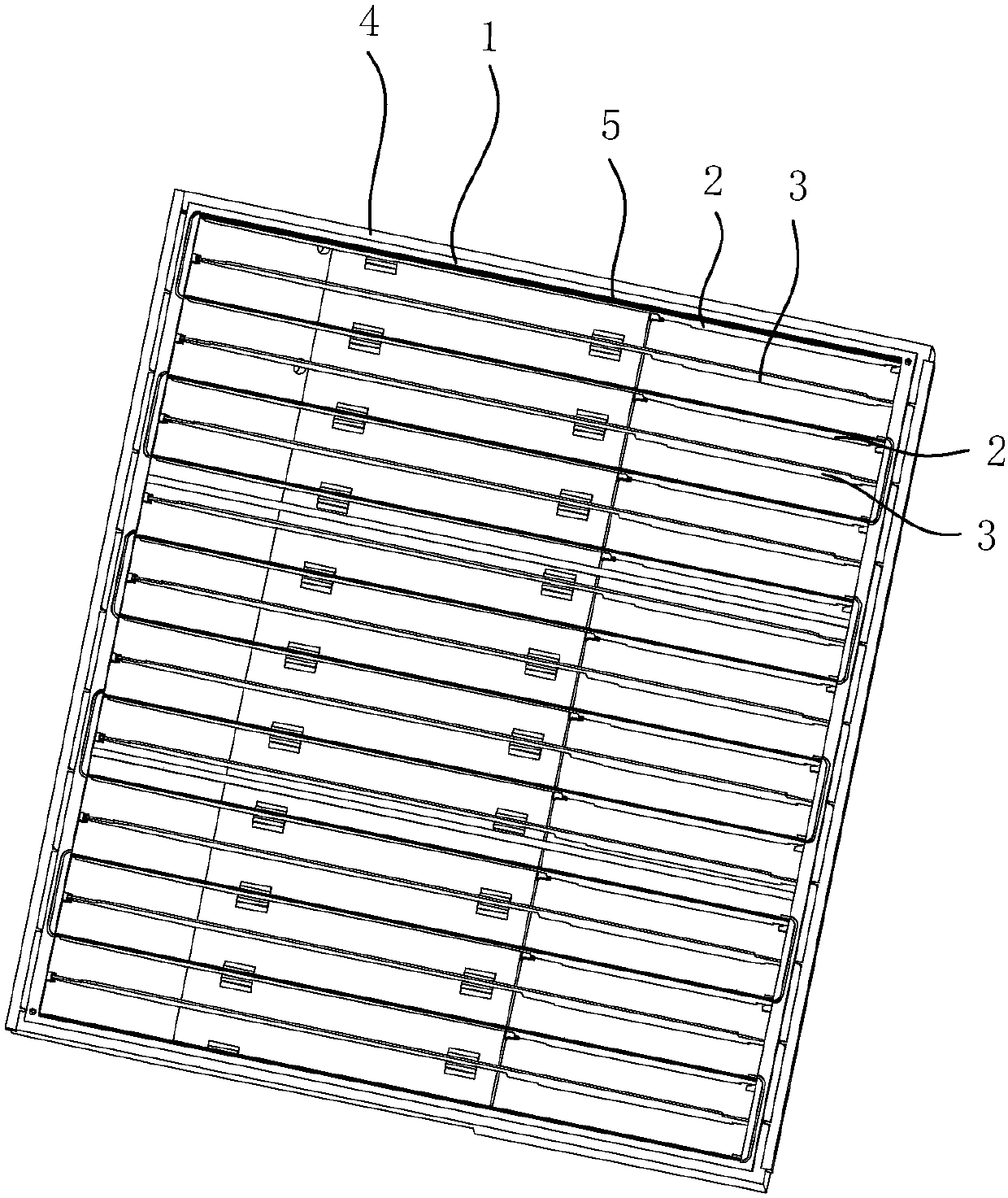

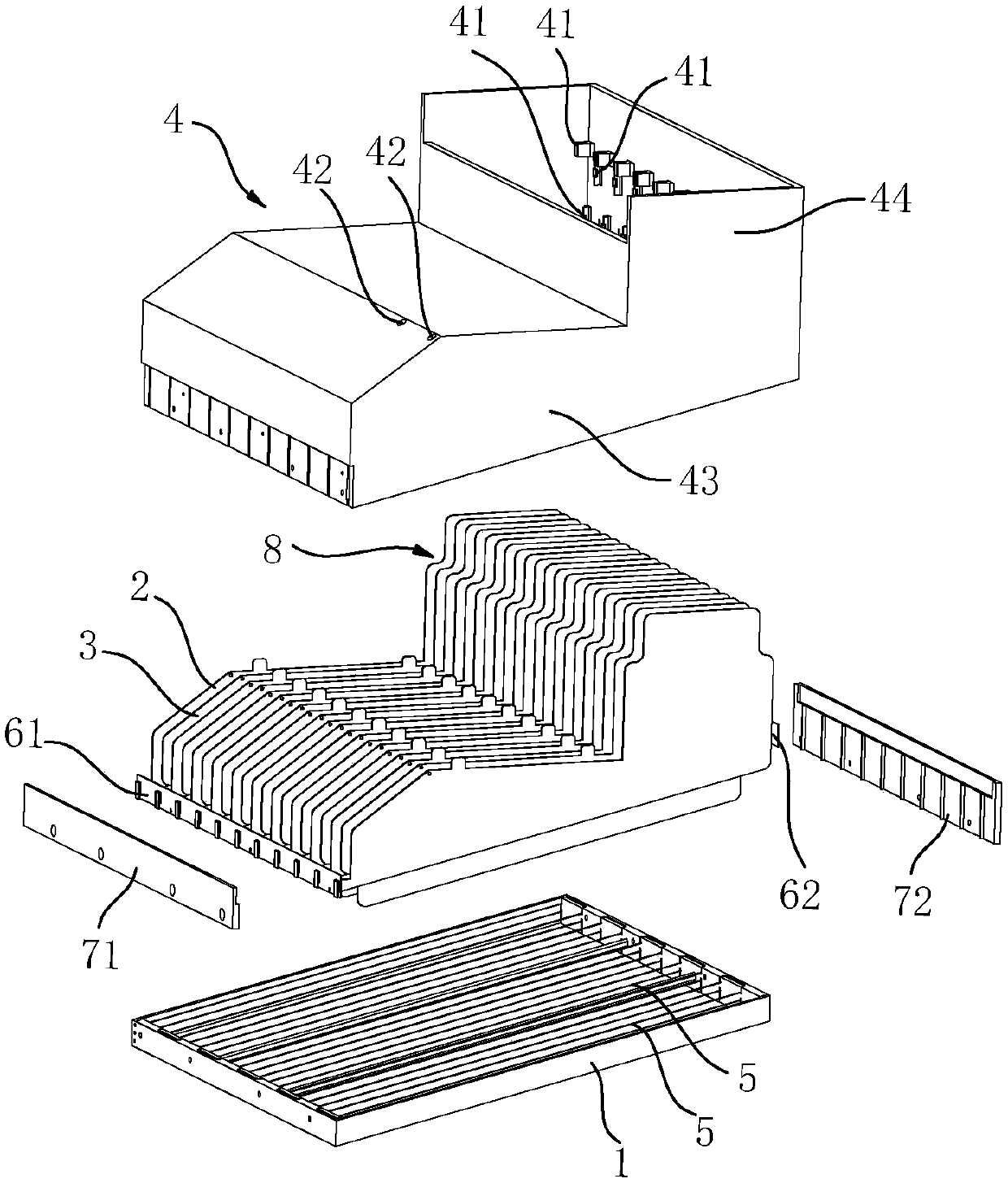

[0024] Such as Figure 1 to Figure 4 As shown, the electrostatic purification device 9 in this embodiment includes main components such as an electrode wire frame 1 , a positive plate 2 , a negative plate 3 , an outer cover 4 , and an electrode wire 5 . Wherein, the electrode wire frame 1 is installed on the bottom of the outer cover 4 , the electrode wire 5 has at least three layers and is installed on the electrode wire frame 1 , and the electrode wire 5 and the positive plate 2 are connected to each other.

[0025] The outer cover 4 has an air inlet portion 43 and an air outlet portion 44 located on one side of the air inlet portion, the air inlet of the outer cover 4 faces downward, the air outlet of the outer cover 4 faces upward, and the positive electrode plate 2 and the negative electrode plate 3 are installed inside the outer cover 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com