lower feeder

A technology for feeding and feeding ammunition, which is applied in the direction of ammunition supply, offensive equipment, weapon accessories, etc., can solve the problems of infantry robot pan/tilt with variable parameters and difficult debugging, etc., to solve the problem of variable pan/tilt parameters, difficult The effect of loading ammunition and facilitating electronic control debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

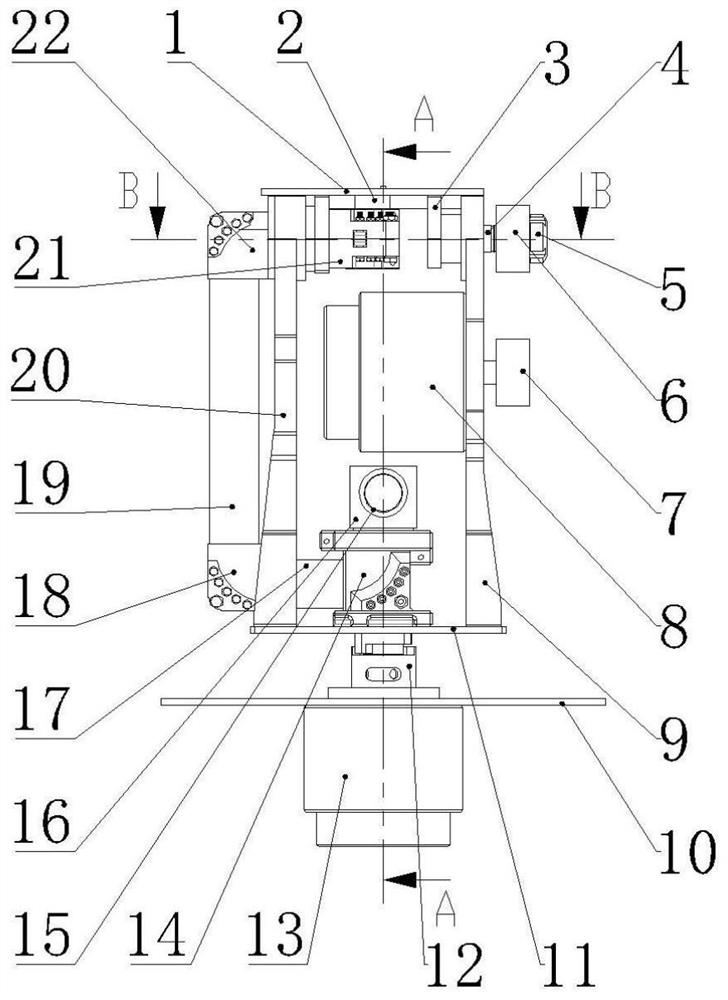

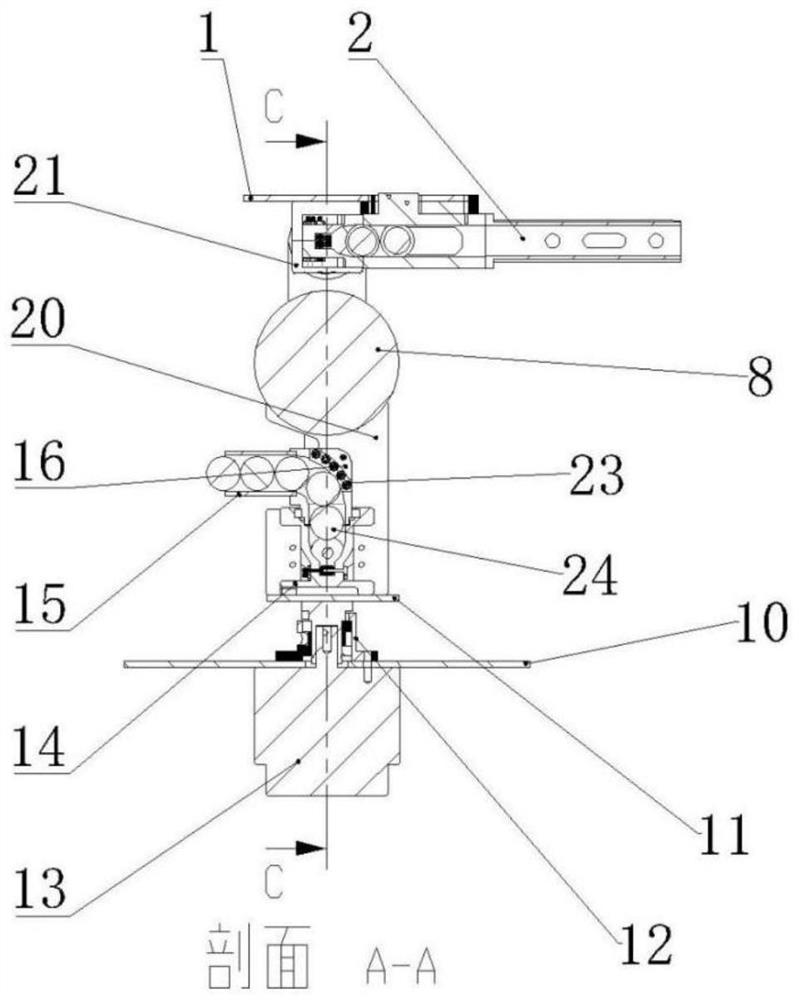

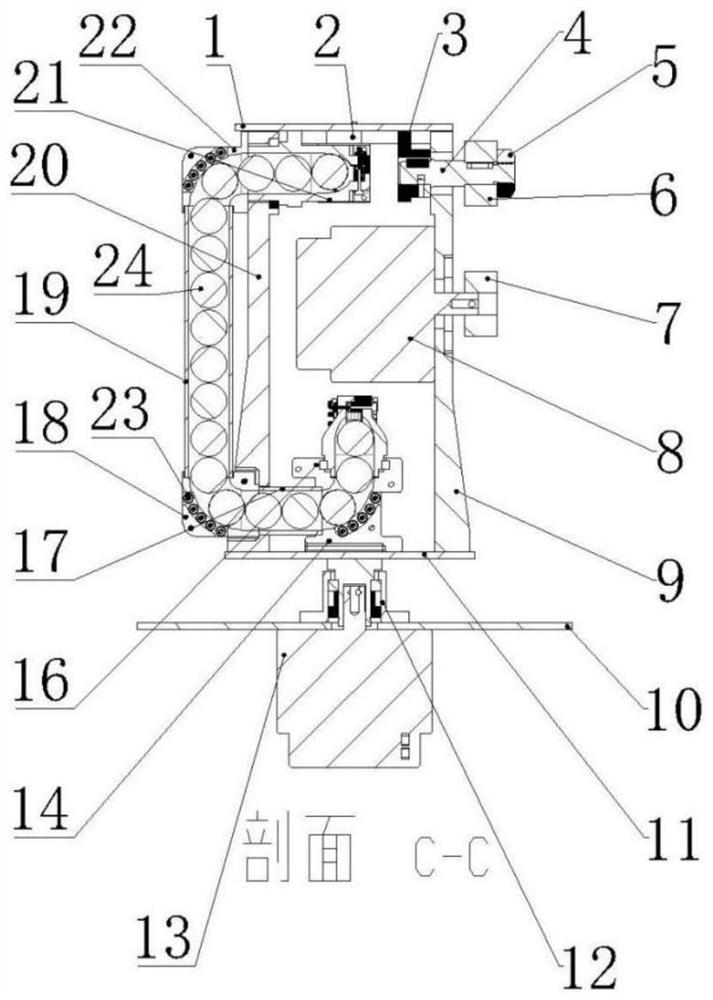

[0014] Such as figure 1 As shown, the present invention includes a pan-tilt upper plate 1, a gun barrel 2, a motor side coupling 3, a synchronous wheel shaft 4, a synchronous wheel stop nut 5, a driven synchronous wheel 6, a driving synchronous wheel 7, an X-axis motor 8, Motor side plate 9, gimbal support plate 10, gimbal lower plate 11, Y-axis coupling 12, Y-axis motor 13, elbow two 14, acrylic tube one 15, elbow one 16, acrylic tube two 17, bend Head 3 18, acrylic tube 3 19, non-motor side plate 20, elbow 5 21, elbow 4 22, elbow bearing 23, 17mm projectile 24 and elbow bolt 25.

[0015] In this embodiment, the Y-axis motor 13 is fixedly connected to the lower plate 11 of the pan-tilt through the Y-axis coupling 12 to realize the horizontal rotation of the pan-tilt. The active synchronous wheel 7 is fixed on the 8-axis of the X-axis motor, and the motor side coupling 3, the driven synchronous wheel 6, and the limit nut 5 of the synchronous wheel are fixed on the synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com