Novel electrostatic rotating cup coating accumulation model of a spraying robot

A technology of spraying robots and electrostatic rotary cups, which is applied in the fields of instruments, electrical digital data processing, and special data processing applications, etc., to achieve the effect of rich expression forms and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

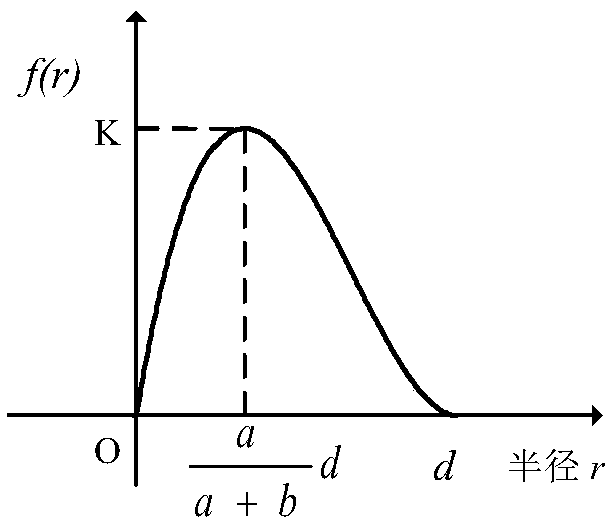

[0033] (1) The double-biased β model represents a non-circular model

[0034] The characteristic of the non-circular model is that the peak value is obtained at the zero point and the function value decreases from the center to both sides, such as Figure 4 As shown, when the non-circular model is represented by the double-biased β model, the offset distance D=0 and the shape parameter a=b=β are required at this time, and d=2D at this time 0 , resolve formula (2) to get formula (3).

[0035]

[0036] This expression is also the classic β distribution model, so the classic β distribution model is a special case of the double-biased β model.

[0037] (2) The double-biased β model represents the circular model

[0038] The characteristic o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com