Method for calculating design pressure of a pipe fitting and a method for determining wall thickness of the pipe fitting

A design pressure and calculation method technology, which is applied to the calculation of the design pressure of pipe fittings and the field of determining the wall thickness of pipe fittings, can solve the problems that the design pressure of pipe fittings cannot be determined, the wall thickness of pipe fittings cannot be calculated, and the wall thickness of elbows cannot be obtained, etc., to achieve Guarantee design life and safety, avoid too thick waste, avoid one-sided effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

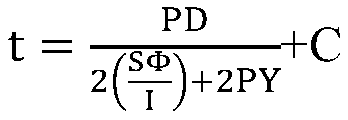

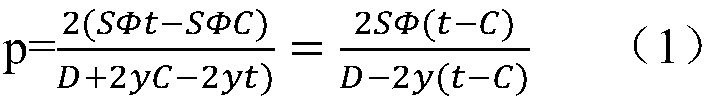

[0083] A method for calculating the design pressure of a pipe fitting, the method comprising:

[0084] (1) Welding elbows are selected for pipe fittings, and the external pipes are connected by butt welding. The elbow code in the order list is: 90o elbow 28”R=1.5DN ASTM A403-WP304 / 304L-WX BW ASME B16.9(RT : 100%) Sch10, from which it can be determined that the external pipe material connected with the pipe fittings is WP304 / 304L and the pipe table number is Sch10;

[0085] (2) Check ASME B36.10M according to the pipe table number, and obtain the nominal thickness of the connected steel pipe: 7.92mm

[0086] (3) Apply the design pressure calculation formula of the pipe fittings

[0087] Among them, the allowable stress of S-pipe at room temperature can be obtained from Table A.1 in GB / T20801.2: S=138MPa

[0088] Φ—weld coefficient, take Φ=1.

[0089] t—nominal thickness of steel pipe, 7.92mm

[0090] C—the additional amount of wall thickness of the steel pipe, C=C1+C2, C1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com