Acid resistant capsules

A technology of capsules and capsule shells, which can be used in capsule delivery, household components, applications, etc., and can solve problems affecting capsule dissolution curves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

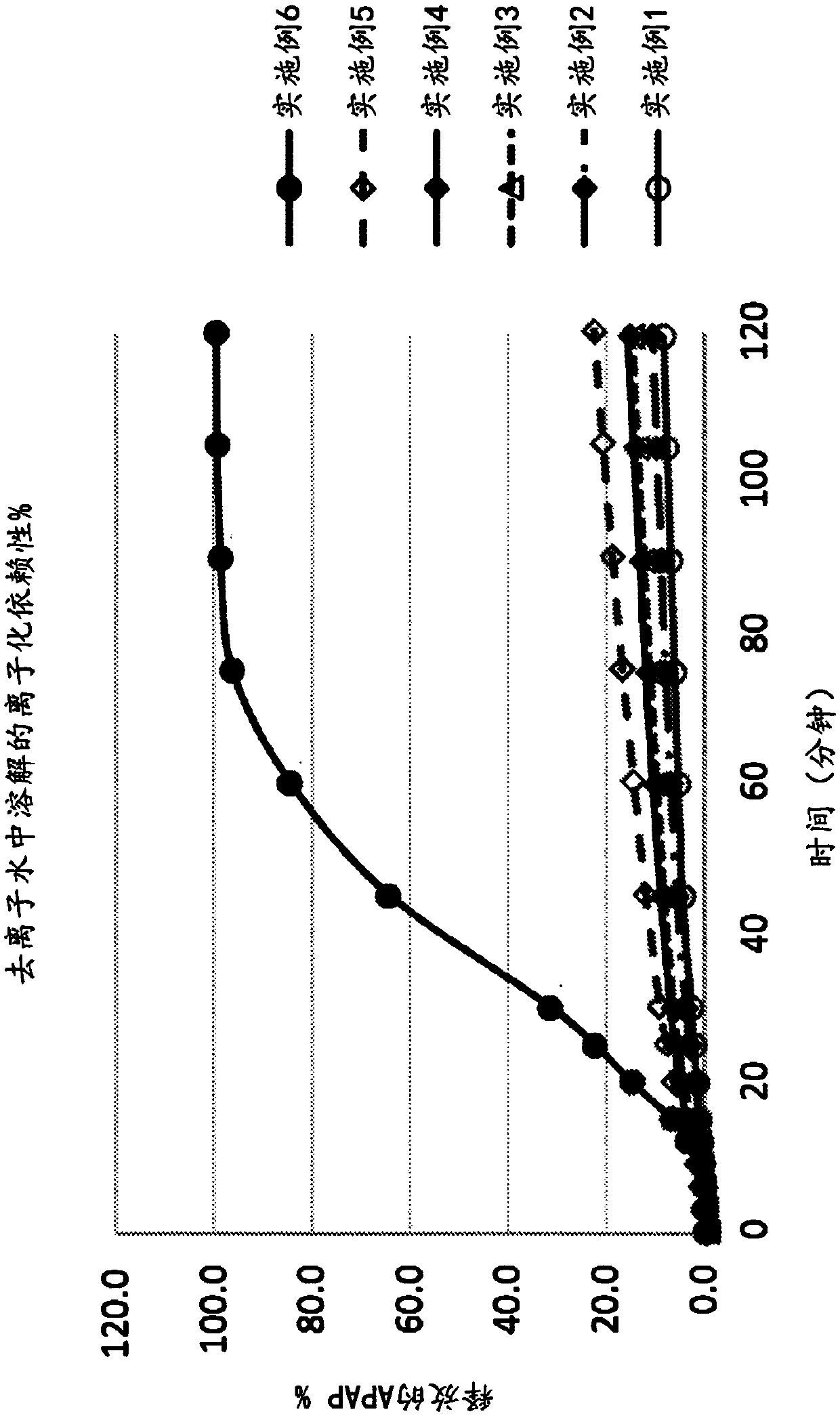

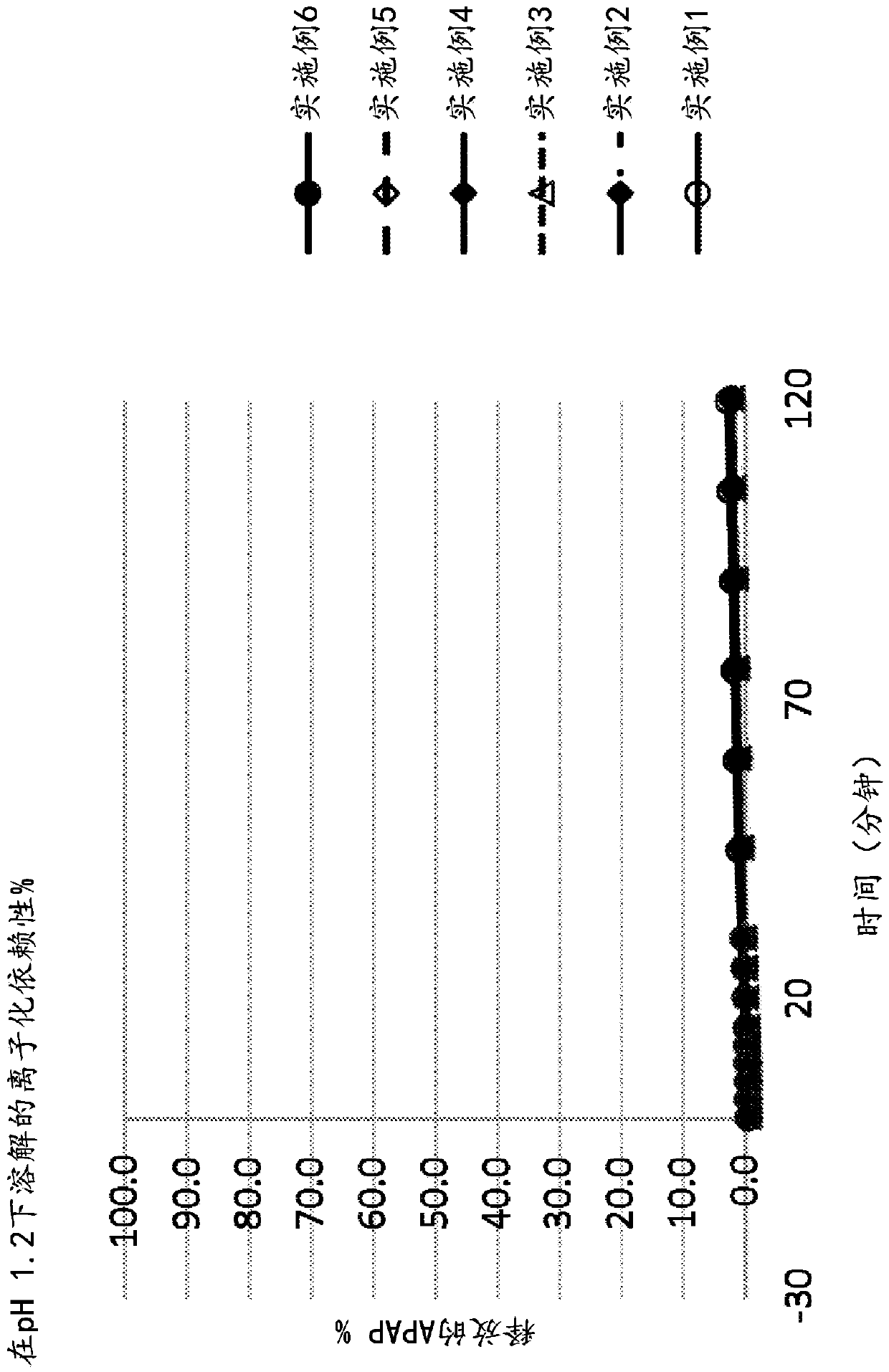

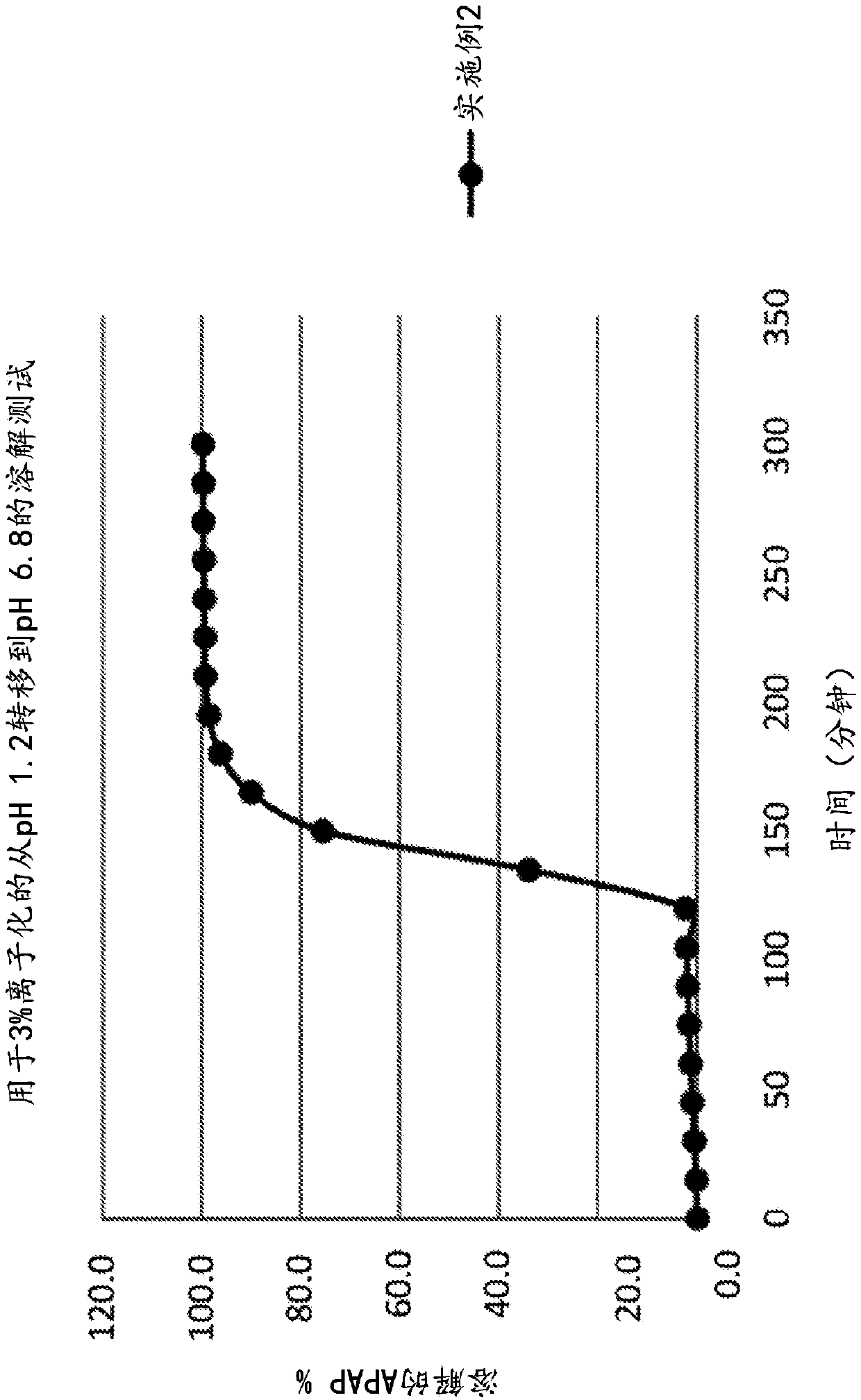

Examples

Embodiment 1 to 8

[0123] Acid-resistant capsules were prepared as follows. The dissolving solution was prepared by adding 153 L of water to a 250 L vessel equipped with a stirrer propeller and anchor at room temperature. While stirring, HPMCAS (32 kg) was dispersed in water. Achieve effective dispersion and avoid foaming by manually adjusting the impeller speed as needed. Ammonia solution from 35% by weight feedstock was added in small aliquots over 30 minutes to achieve an initial pH of 5.8 to 5.9. The solution was then stirred for 2 hours until visually all HPMCAS appeared to be dissolved. Additional ammonia solution was added in small aliquots at 30 minute intervals to achieve a target pH of 6.00 + / - 0.05. The total amount of ammonia solution added in these steps was 2.34 kg. After the pH stabilized, 59 L of a 21 wt% HPMC solution was added to the vessel at room temperature. The resulting solution was then stirred for 1 hour to homogenize. The solution was then kept at room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com