Differential reduction gear, drive mechanism for crane, and shoreside container crane

A technology of differential deceleration and transmission shaft, which is applied in the direction of traveling mechanism, heavy-duty pulley, transportation and packaging, etc., can solve problems such as multiple sets of deceleration devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

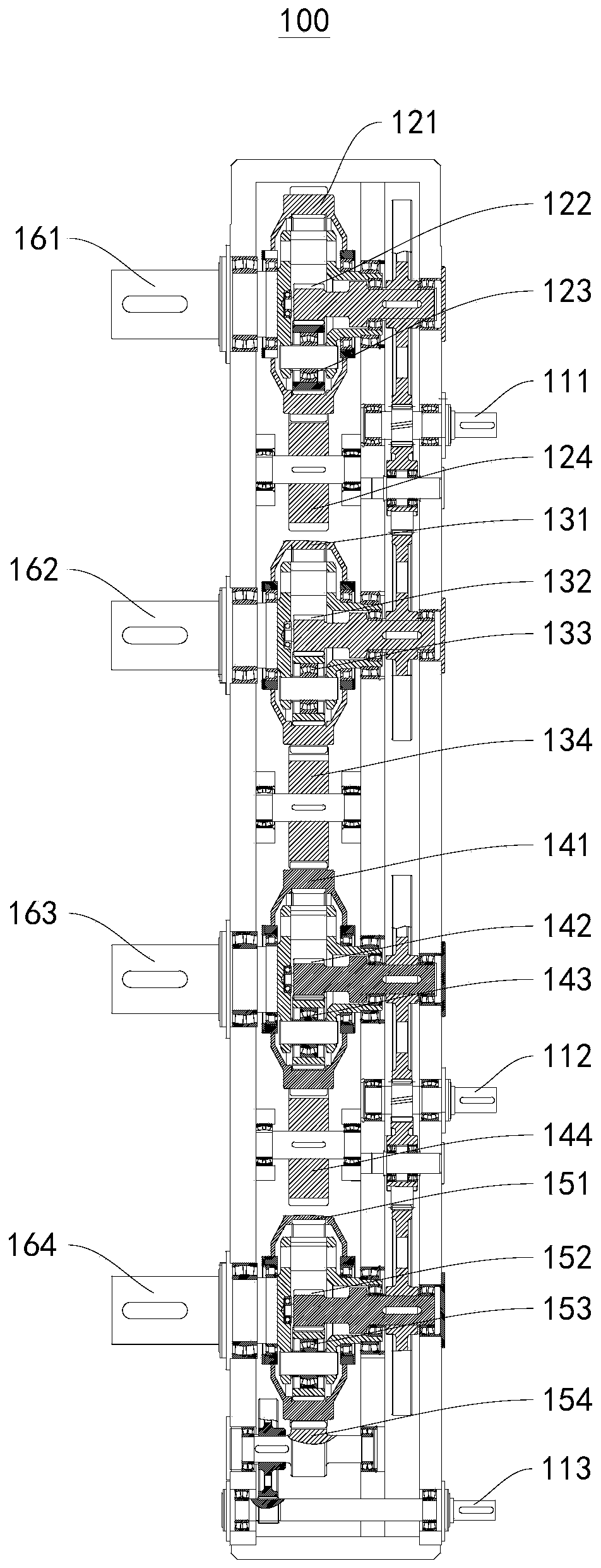

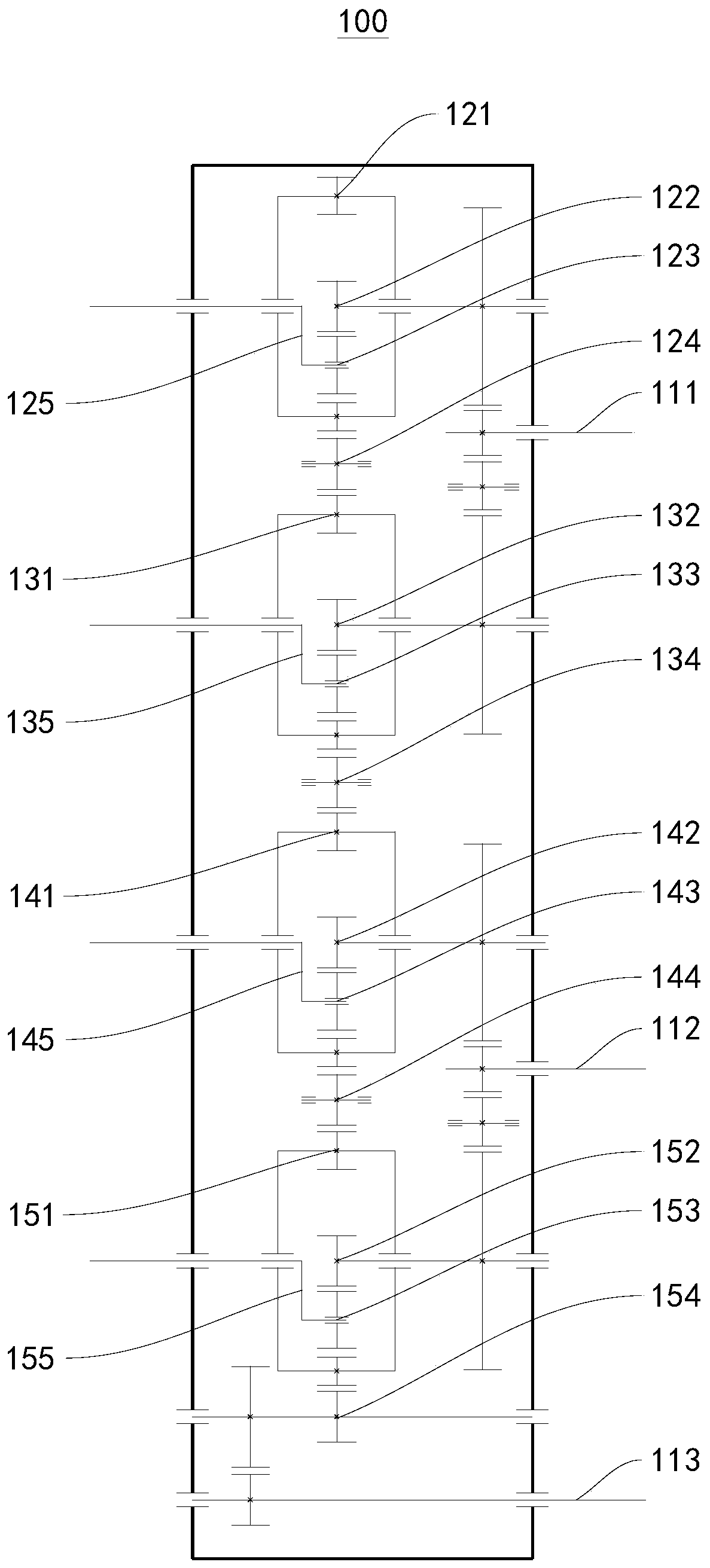

[0075] This embodiment provides a differential reduction device 100, please refer to figure 1 and figure 2 ,

[0076] This differential reduction device 100 includes:

[0077] The first planetary gear 123 series, the first planetary gear 123 series includes the first ring gear 121, the first sun gear 122, the first planetary gear and the first planet carrier 125, the first planetary gear and the first ring gear 121 and the first planetary carrier 125 respectively A sun gear 122 meshes, and the first planet carrier 125 is connected to the first sun gear 122;

[0078] The second planetary gear 133 series, the second planetary gear 133 series includes the second ring gear 131, the second sun gear 132, the second planetary gear and the second planetary carrier 135, the second planetary gear and the second ring gear 131 and the second planetary carrier 135 respectively. The second sun gear 132 meshes, and the second planet carrier 135 is connected to the second sun gear 132;

...

Embodiment 2

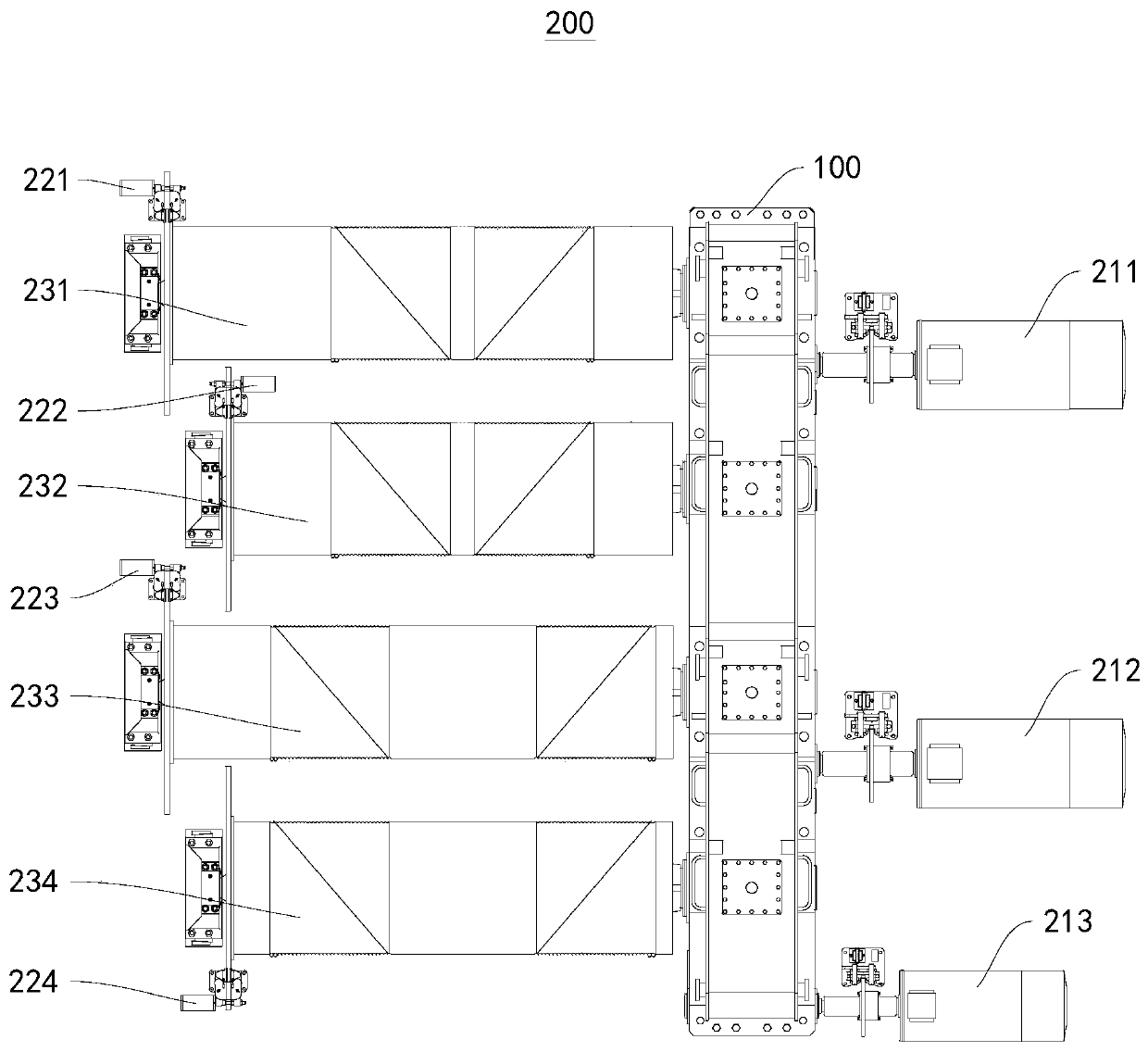

[0110] This embodiment provides a driving mechanism 200 for a crane, please refer to image 3 ,

[0111] The driving mechanism 200 for a crane includes: the differential speed reduction device 100 provided in the first embodiment and,

[0112] The first driving member 211, the first driving member 211 and the first transmission shaft 111 are connected in transmission;

[0113] The second driving member 212, the second driving member 212 and the second transmission shaft 112 are connected in transmission;

[0114] The third driving member 213, the third driving member 213 and the third transmission shaft 113 are connected in transmission;

[0115] The first reel 231, the first reel 231 and the first planet carrier 125 are connected by transmission;

[0116] The second reel 232, the second reel 232 and the second planet carrier 135 are connected by transmission;

[0117] The third reel 233, the third reel 233 and the third planet carrier 145 are connected by transmission;

...

Embodiment 3

[0124] This embodiment provides a shoreside container crane 300, please refer to Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 as well as Figure 9 ,

[0125] This shoreside container crane 300 includes the crane driving mechanism 200 provided in the first embodiment and,

[0126] The first hanger upper frame 320 has a first connection assembly and a second connection assembly on the first spreader upper frame 320. The first connection assembly is connected to the first reel 231 through the first connection group line, and the second connection assembly is connected through the second connection assembly. The connecting group wire is connected to the second reel 232;

[0127] The second hanger upper frame 340, the second hanger upper frame 340 has a third connection assembly and a fourth connection assembly, the third connection assembly is connected with the third reel 233 through the third connection group line, and the fourth connection assembly is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com