Stove and rotary knob

A technology of knobs and stoves, which is applied in the field of stoves and knobs, and can solve the problems of plastic aging, melting, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

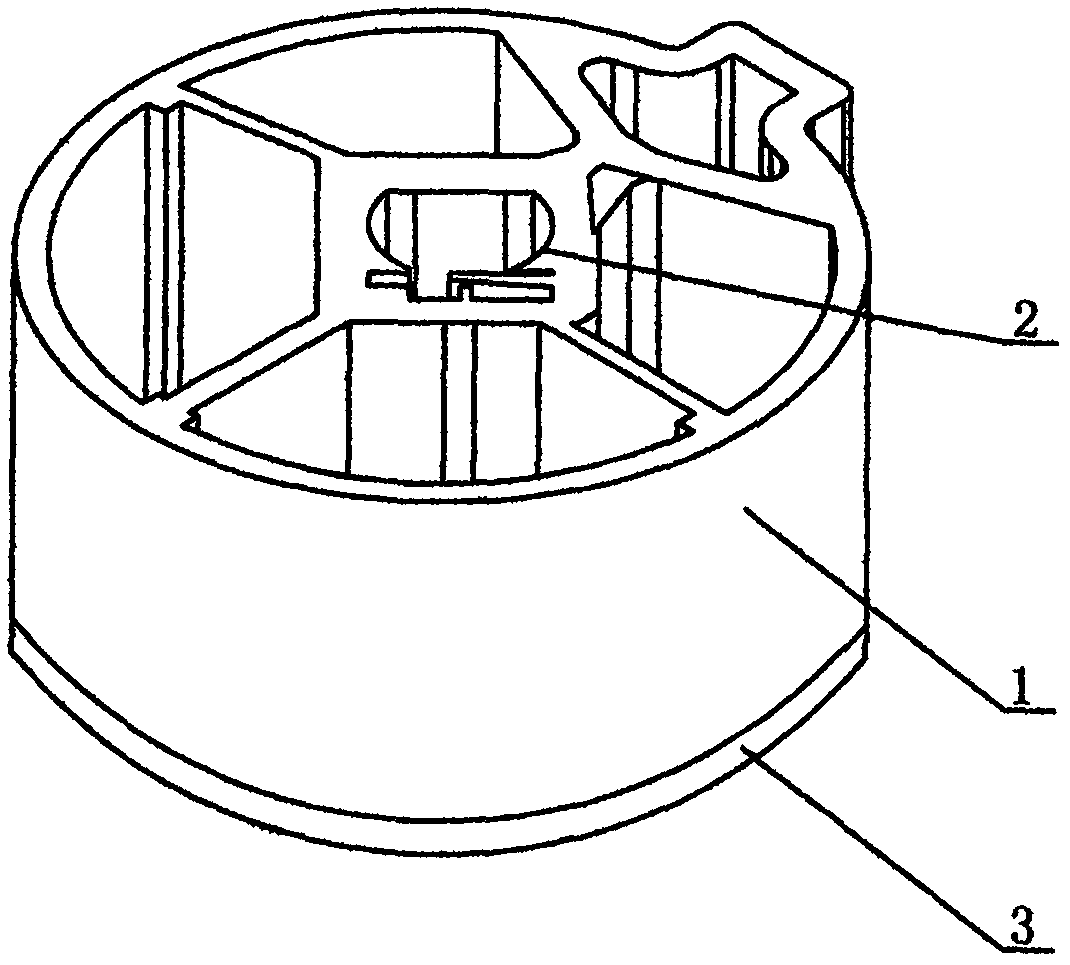

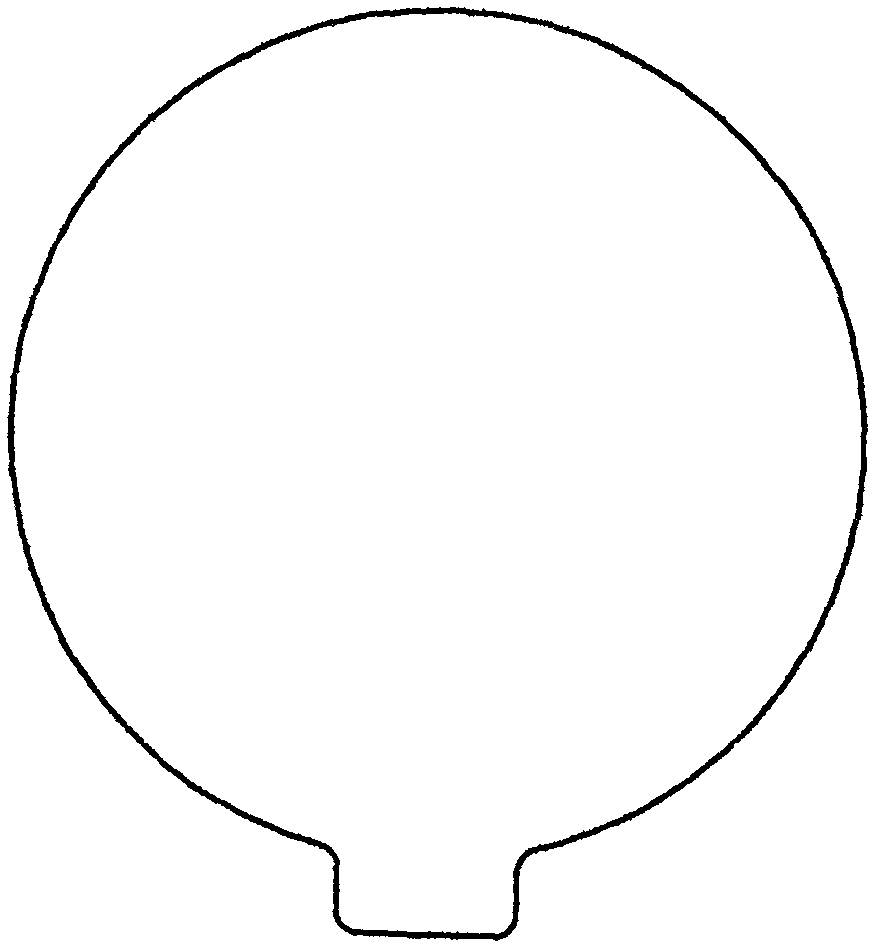

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , the knob includes a handle part (1), a connecting part (2) and a decorative part (3). The central part of the knob is the connecting part (2), and the connecting part (2) includes a "D"-shaped hole and a cantilever "\"-shaped protrusion (21) for interference fit, and the connecting part (2) It includes a protrusion (22) for preventing the protrusion (21) from being plastically deformed, and the holding part (1) and the connecting part (2) are connected through a reinforcing rib (23). The connecting part (2) of the knob of the present invention has a protrusion (21) which can be matched with an external connecting piece, and the protrusion (21) is more likely to produce elastic deformation under pressure than a smooth surface. Therefore, the external connecting piece with large tolerances in matching dimensions can be more easily assembled to the connecting portion (2) of the knob of the present invention through ...

Embodiment 2

[0025] Such as Figure 5 , the knob includes a gripping part (1) and a connecting part (2). The connecting part (2) is a shaft connected with the outside. The shaft has features to prevent it from coming out, such as grooves or radial holes or dimples.

Embodiment 3

[0027] Such as Image 6 , the present invention also proposes a cooker (1), which includes the knob (2) as described in Embodiment 1 above. The cooker may be a gas cooker, an electromagnetic cooker, an alcohol fuel cooker or other types of cooker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com