A low water peak large-size optical fiber preform and its manufacturing method

A technology of optical fiber preform and manufacturing method, which is applied in the direction of manufacturing tools, glass manufacturing equipment, glass fiber products, etc., can solve the problems of increasing optical fiber attenuation, high hydroxyl content, limiting the use of optical fibers, etc., to reduce concentricity errors, reduce Effect of attenuation and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

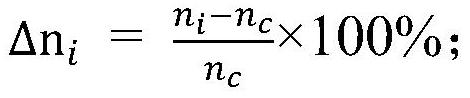

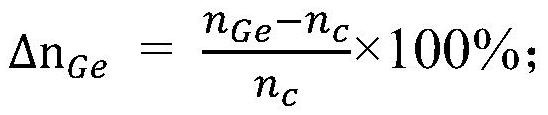

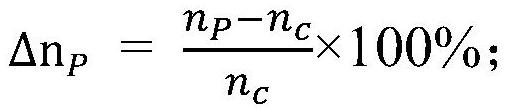

[0037] The solid prefabricated mandrel is prepared by MCVD process: firstly, the fluorine-doped quartz tube is heated to 600 ° C, and SF6 gas is introduced into the fluorine-doped quartz tube to chemically etch the inner surface of the base tube to remove impurities on the inner surface of the fluorine-doped quartz tube. The relative refractive index of the fluorine-doped quartz tube is Δn 1 =-0.32%; secondly, at 1950 ° C, deposit an inner cladding layer on the inner wall of the fluorine-doped quartz tube, and in the reaction gas silicon tetrachloride and oxygen, pass a fluorine-containing gas (SiF 4 ) and germanium tetrachloride to form a GeO2-F co-doped inner cladding, and the relative refractive index of the inner cladding is Δn 2 =0.01%, where the doping contribution of Ge is Δn Ge The core layer was deposited on the inner cladding layer at 1700°C, and fluorine-containing gas (SiF) was introduced into the reaction gas silicon tetrachloride and oxygen 4 ) and phosphorus o...

Embodiment 2

[0041] The solid prefabricated mandrel is prepared by MCVD process: first, the fluorine-doped quartz tube is heated to 700°C, and SF6 gas is introduced into the fluorine-doped quartz tube to chemically etch the inner surface of the substrate tube to remove impurities on the inner surface of the fluorine-doped quartz tube. The relative refractive index of the fluorine-doped quartz tube is Δn 1 =-0.45%; followed by depositing an inner cladding on the inner wall of the fluorine-doped quartz tube at 2000°C, and feeding a fluorine-containing gas (SiF 4 ) and germanium tetrachloride to form an inner cladding layer co-doped with GeO2-F, and the relative refractive index of the inner cladding layer is △n 2 =0.02%, where Ge doping contribution Δn Ge 0.05%; finally at 1800°C, deposit a core layer on the inner cladding layer, and in the reaction gas silicon tetrachloride and oxygen, pass a fluorine-containing gas (SiF 4 ) and phosphorus oxychloride to form P 2 O 5 -F co-doped core la...

Embodiment 3

[0045] The solid prefabricated mandrel is prepared by MCVD process: firstly, the fluorine-doped quartz tube is heated to 550°C, and SF6 gas is introduced into the fluorine-doped quartz tube to chemically etch the inner surface of the substrate tube to remove impurities on the inner surface of the fluorine-doped quartz tube. The relative refractive index of the fluorine-doped quartz tube is Δn 1 =-0.12%; Next, at 1850°C, the inner cladding is deposited on the inner wall of the fluorine-doped quartz tube, and the fluorine-containing gas (SiF 4 ) and germanium tetrachloride to form an inner cladding layer co-doped with GeO2-F, and the relative refractive index of the inner cladding layer is △n 2 =-0.02%, where Ge doping contribution Δn Ge 0.01%; Finally, at 1650°C, deposit a core layer on the inner cladding layer, and in the reaction gas silicon tetrachloride and oxygen, pass a fluorine-containing gas (SiF 4 ) and phosphorus oxychloride to form P 2 O 5 -F co-doped core layer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com