Wind power generator set

A technology for wind turbines and fans, which is applied to wind turbines, wind energy power generation, engines, etc., can solve the problems of high construction requirements for installing water-cooling pipes and leakage of coolant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

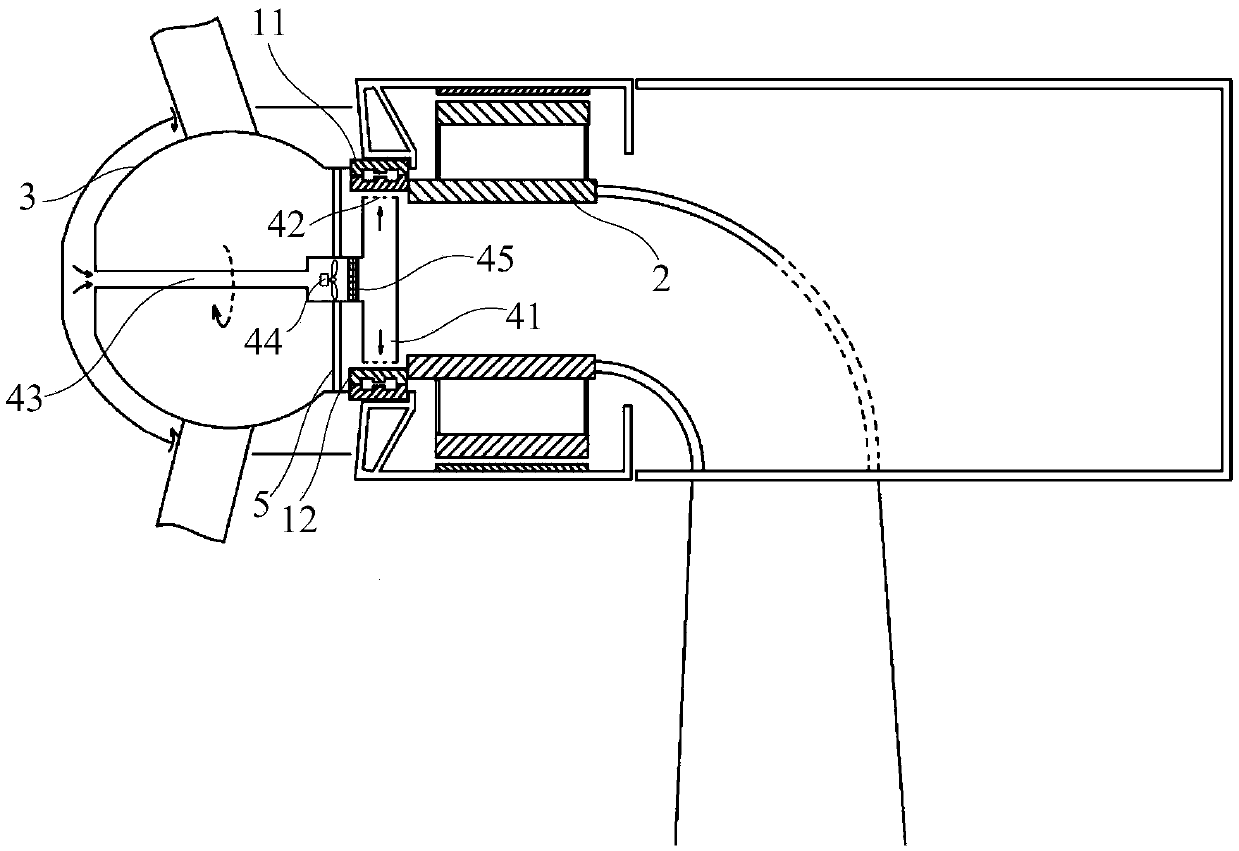

[0045] Such as figure 1 As shown, the present invention provides a wind power generating set, which includes a bearing system, and the bearing system includes a bearing outer ring 11 and a bearing inner ring 12 . The wind power generating set also includes a fixed shaft 2 and a hub 3, the fixed shaft 2 is fixed to the bearing inner ring 12, and the hub 3 is fixed to the bearing outer ring 11. The wind power generating set also includes an air cooling system, which includes an air outlet pipeline 41 and an air inlet pipeline 43, the air outlet pipeline 41 is located in a radial direction of the bearing inner ring 12, and one end thereof is aligned with the bearing inner ring 12 The inner side surface of the bearing inner ring 12 has a partial gap. The air outlet pipeline 41 can rotate around the central point of the bearing inner ring 12 . Preferably, the wind power generating set is provided with two air outlet pipelines 41, one end of the two air outlet pipelines 41 is loca...

Embodiment 2

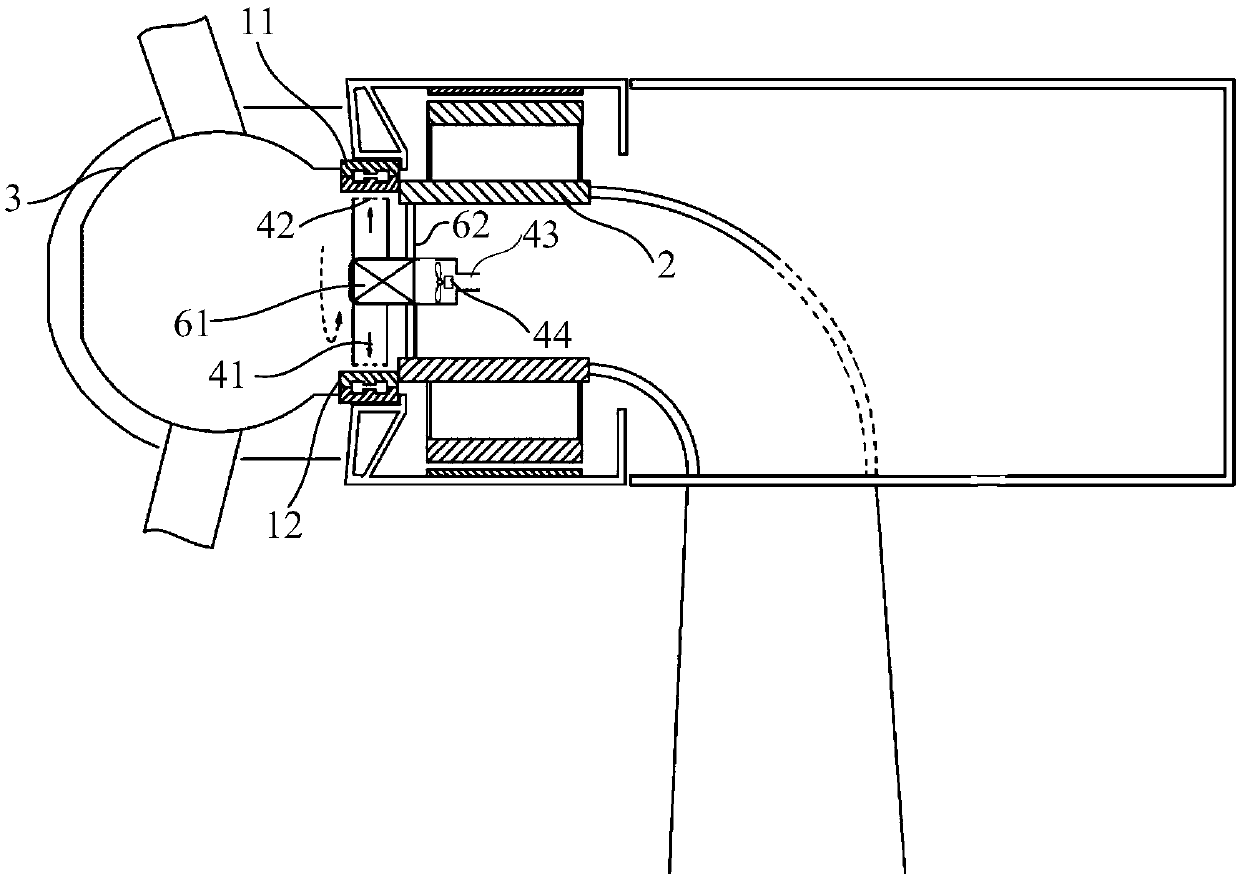

[0051] Such as figure 2 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, and the difference is that the air cooling system also includes a driving device, which includes two support rods 62 and a drive bearing 61, and one end of the support rod 62 is welded On the fixed shaft 2, the other end is connected with a drive bearing 61. The driving device also includes a motor connected inside the driving bearing 61 for driving the driving bearing 61 to rotate. The drive bearing 61 is located at the center point of the bearing inner ring 12 and can rotate around the center point. One end of the air inlet pipeline 43 is connected and fixed to the drive bearing 61 , and the other end is located at the inner space of the nacelle of the wind power generating set.

[0052] An electric control device is also installed on the driving bearing 61, and the rotating speed of the driving bearing 61 is controlled by controlling the motor. During use, t...

Embodiment 3

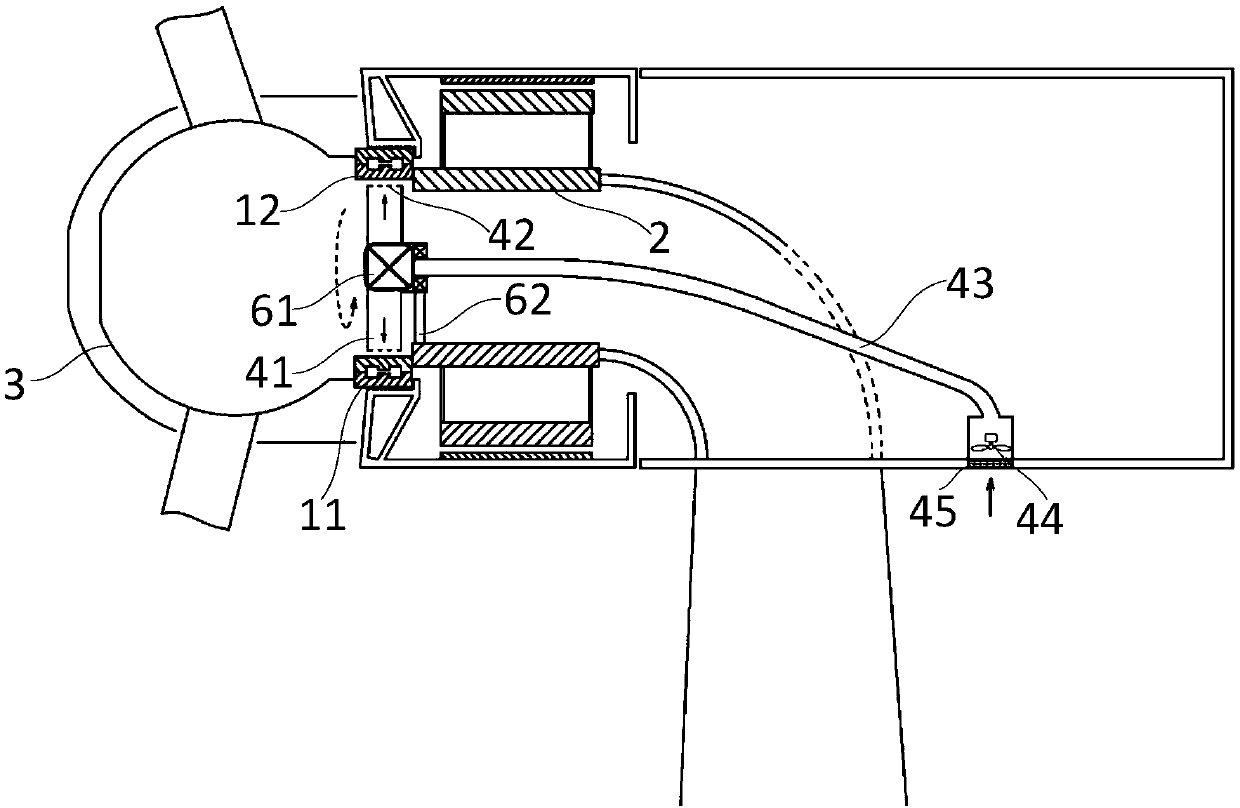

[0056] Such as image 3 As shown, the structure of this embodiment is basically the same as that of Embodiment 2, the difference is that one end of the air inlet pipeline 43 is connected and fixed to the drive bearing 61, and the other end of the air inlet pipeline 43 is welded to the wind power generating set cabin wall.

[0057] When the system of the wind power generating set starts to run, after the surface temperature of the bearing inner ring 12 rises to a certain level, the driving device is turned on, so that the air cooling system starts to rotate around the center point of the bearing inner ring 12, and then drives the air outlet pipe The circuit 41 rotates, and then the fan device 44 is turned on, and the external cooling air is extracted through the air inlet pipe 43, and then sprayed on the surface of the bearing inner ring 12 to achieve the effect of cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com