An assembly method of a miniature standard rolling bearing crown cage

A rolling bearing and assembly method technology, which is applied in the directions of shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems of sticking, poor rotation flexibility, unqualified rotation flexibility, etc., and achieves improved rotation flexibility and uniform force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

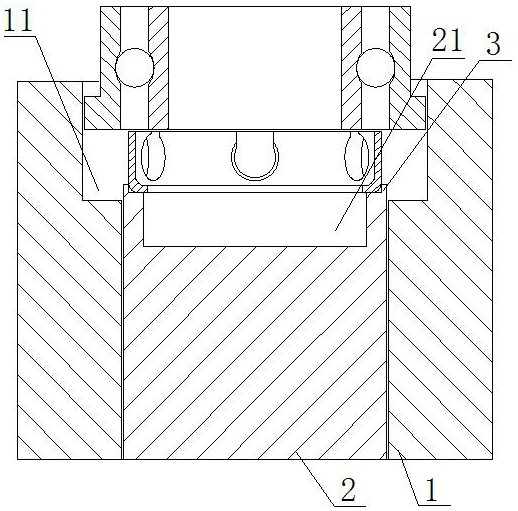

[0027] Terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit the scope of the present invention. The scope of implementation and the change or adjustment of its relative relationship shall also be regarded as the scope of implementation of the present invention without substantive changes in technical content.

[0028] The core of the invention is to provide a method for assembling the crown-shaped cage of the miniature standard rolling bearing, which ensures that the crown-shaped cage is evenly stressed and does not deform.

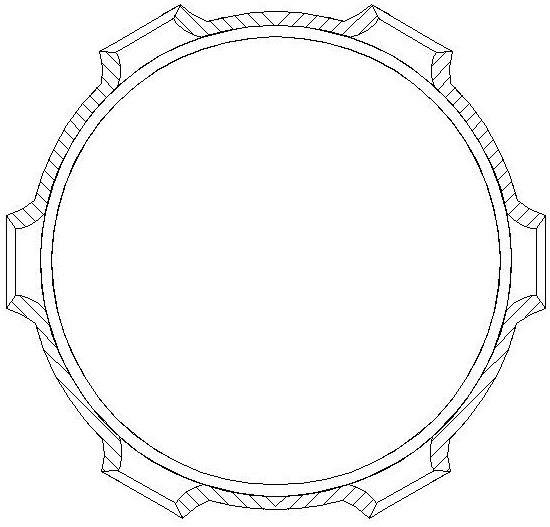

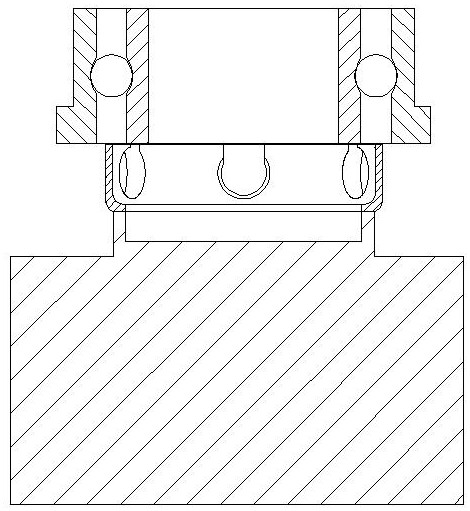

[0029] This measurement method is especially suitable for cases where the height of the crown cage is small and it is located in the middle of the bearing. For the miniature standard rolling bearings shown in the accompanying drawings, the total height of the crown cage is half of the total height of the bearing. Wherein, the groove bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com