Detector for detecting outline cross section shape of bridge cable

A cross-sectional shape and bridge cable technology, which is applied in the field of detectors for detecting the cross-sectional shape of bridge cables, can solve problems such as complex electromagnetic systems and mechanical devices, and are prone to misjudgments, and achieve simple data processing, great application value, and The effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The working process of a detector for detecting the cross-sectional shape of a bridge cable is as follows:

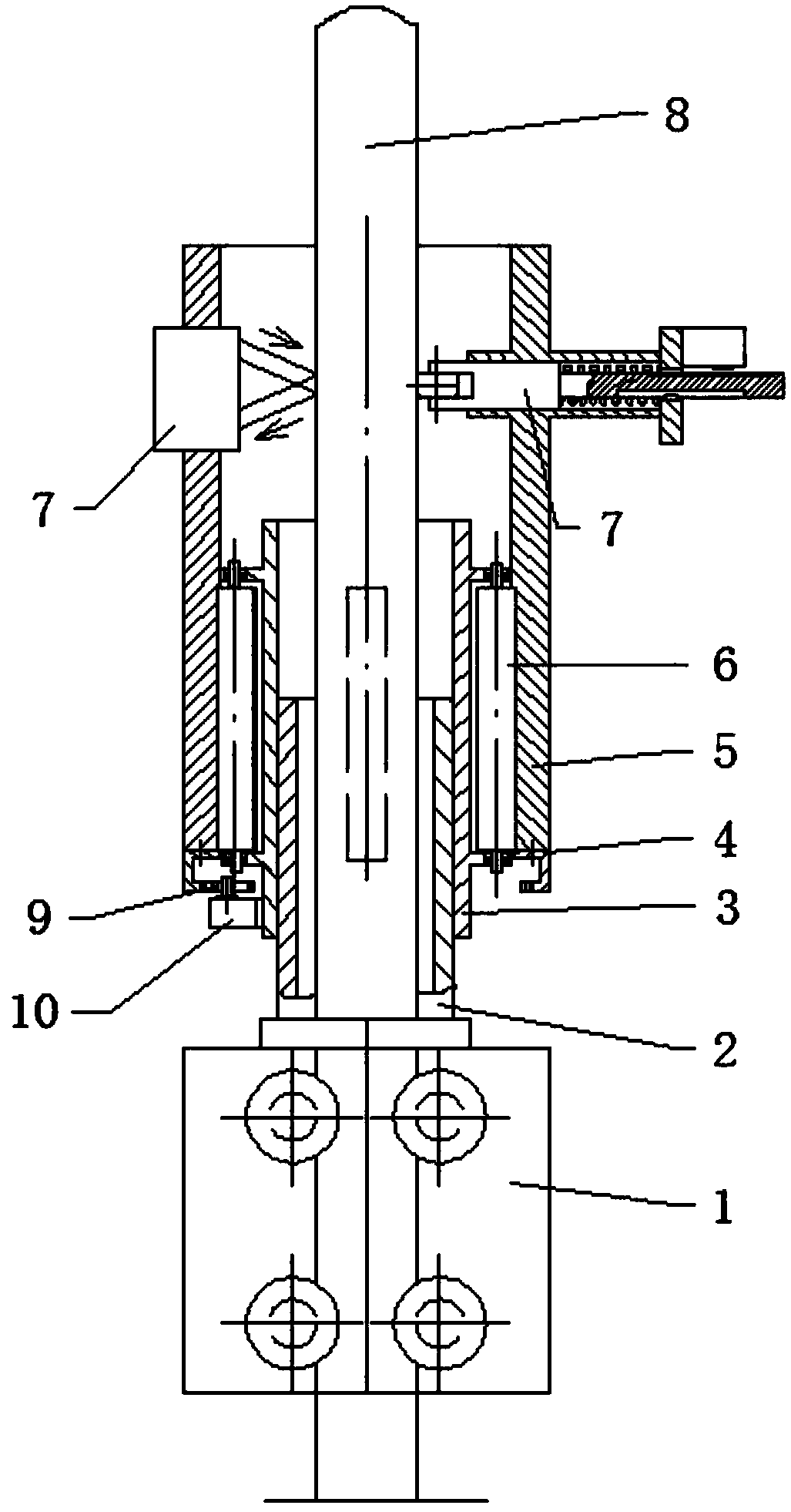

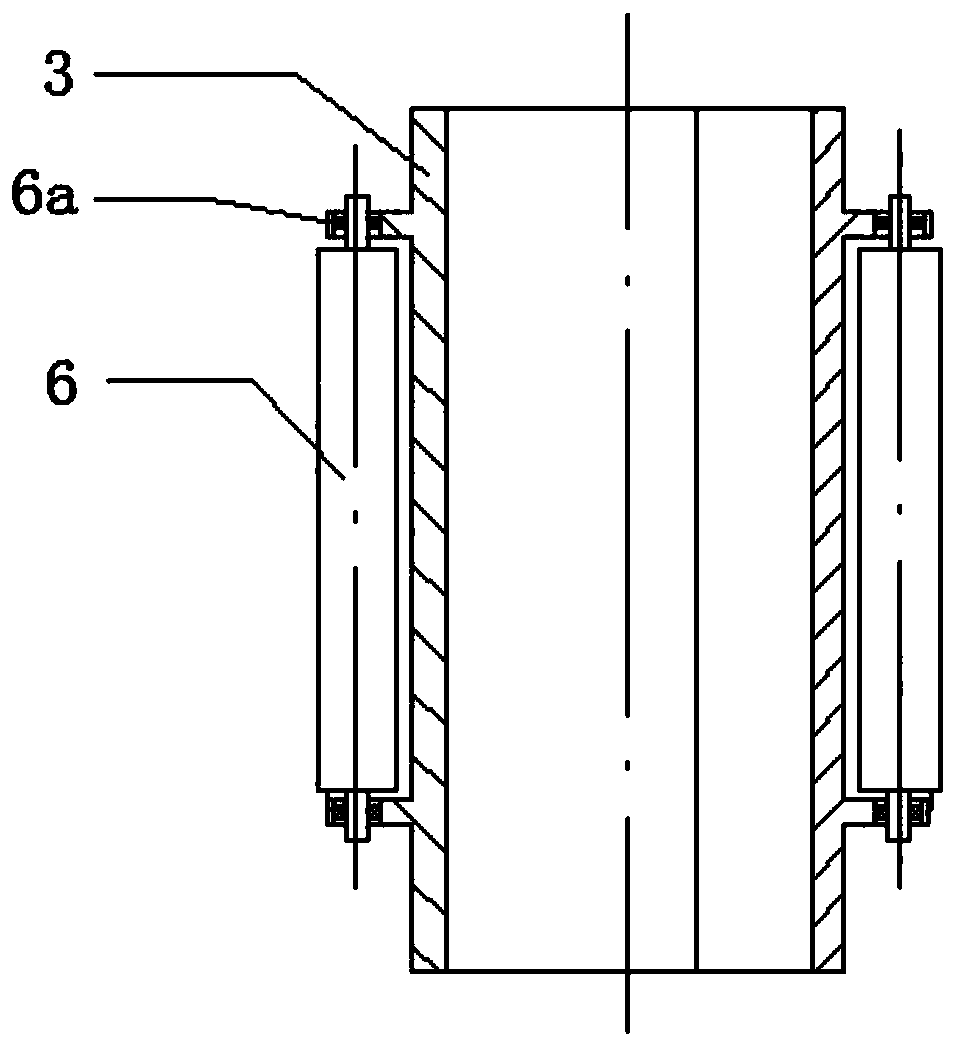

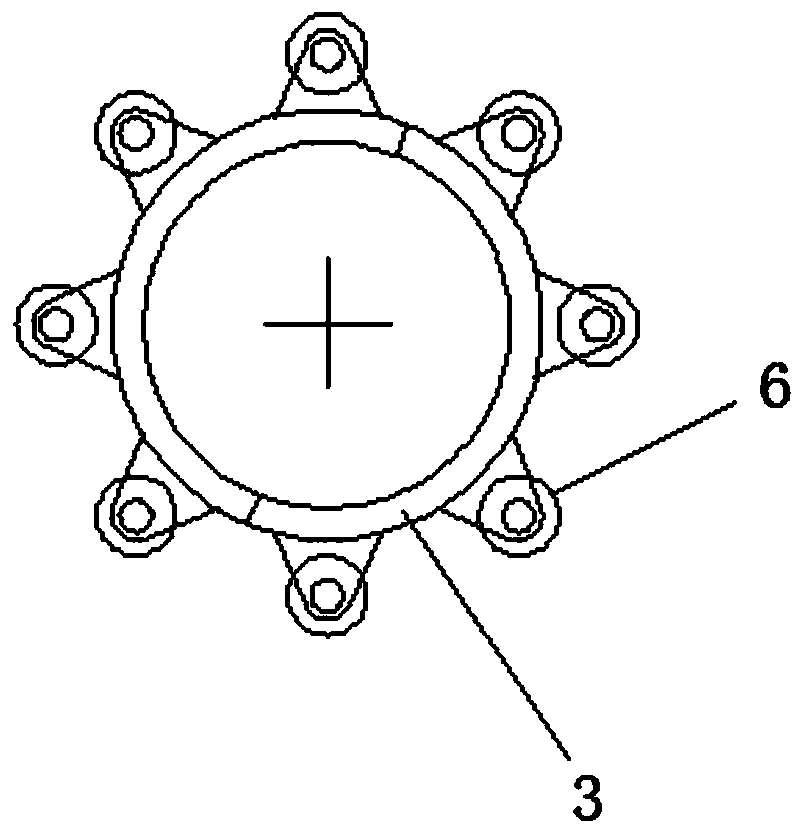

[0035] Install the professional crawling robot 1 on the tested cable cylinder 8, design a transition sleeve 2 to be coaxially mounted on the crawling robot 1 in two semicircles of the same diameter, and the slewing support 3 in two semicircles of the same diameter It is fixedly connected with the transition sleeve 2, and several rollers 6 are installed on the slewing support 3, and several rollers 6 are distributed around the outer circumference of the slewing support 3, and the slewing sleeve 5 is mounted on the rollers 6 in two semicircles with the same diameter The rotary sleeve 5 is connected with two coaxial semicircular passive transmission gears 4 and the driving gear 9 with the same diameter. Driven by the motor 10, it rotates forward and backward around the cable drum 8, and the distance measuring sensor 7 of the cable section installed on the rotary sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com