A shape memory alloy levitation device for micro-force measurement of superconducting magnetic levitation

A technology of memory alloy and memory alloy spring, which is applied in the field of shape memory alloy floating device, can solve the problems of operation error, precision measurement influence, permanent magnet movement interference, etc., and achieve the effect of easy processing, easy realization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

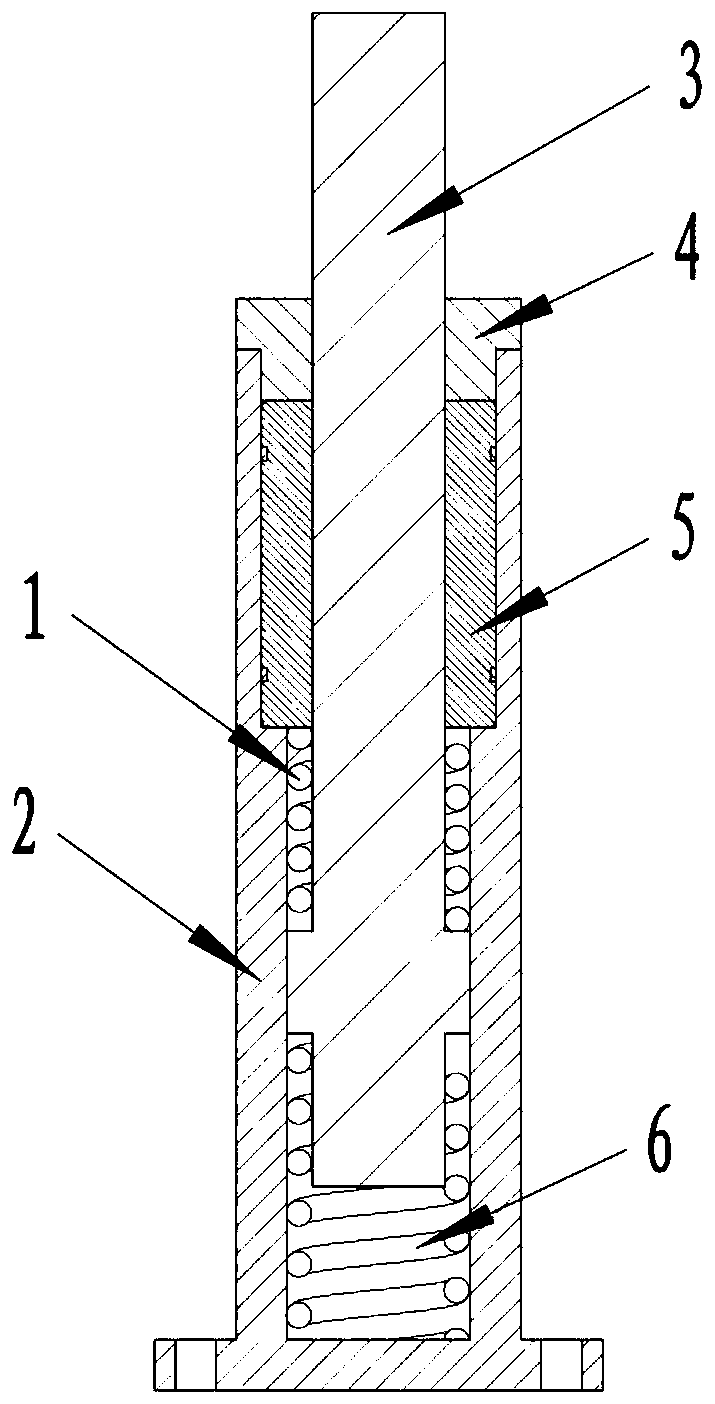

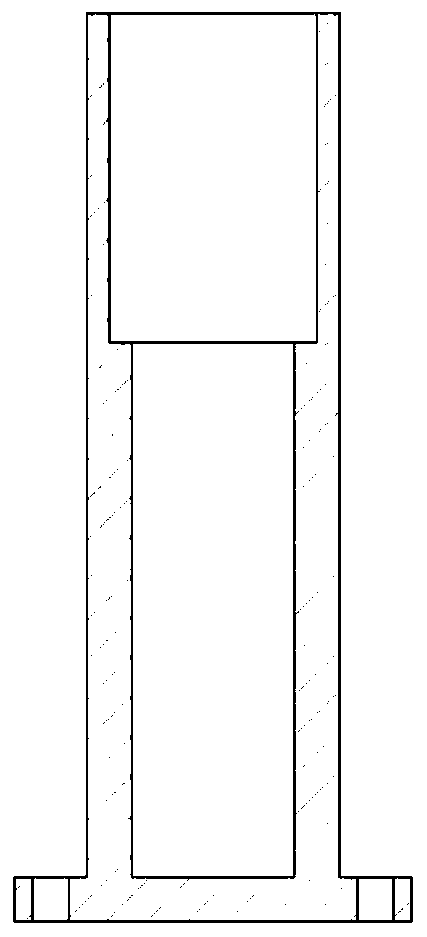

[0022] The present invention is a shape-memory alloy floating device used for superconducting magnetic levitation micro-force measurement. The change of two states is realized by changing the temperature: the lifting and floating of the floating object. The device has a simple structure, no electromagnetic interference, and the state is easy to control . Specifically, the floating device is fixed on a plane. Under the control of temperature, the support rod is driven to move up and down by the memory alloy spring, and the support rod is restrained by the cooperation between the linear bearing and the support rod to avoid the support rod from shaking left and right, thereby Drive the floating object to float smoothly and without magnetic field interference.

[0023] The floating device as described figure 1 As shown, it includes a sleeve 2 , a sleeve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com