Variational Nonlinear Mode Decomposition Method for Fault Diagnosis of Variable Speed Bearings

A mode decomposition and fault diagnosis technology, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve problems such as inaccurate ridge frequency information, poor aggregation of time-frequency diagrams, and poor timeliness. Achieve the effect of reducing the amount of calculation, improving accuracy and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

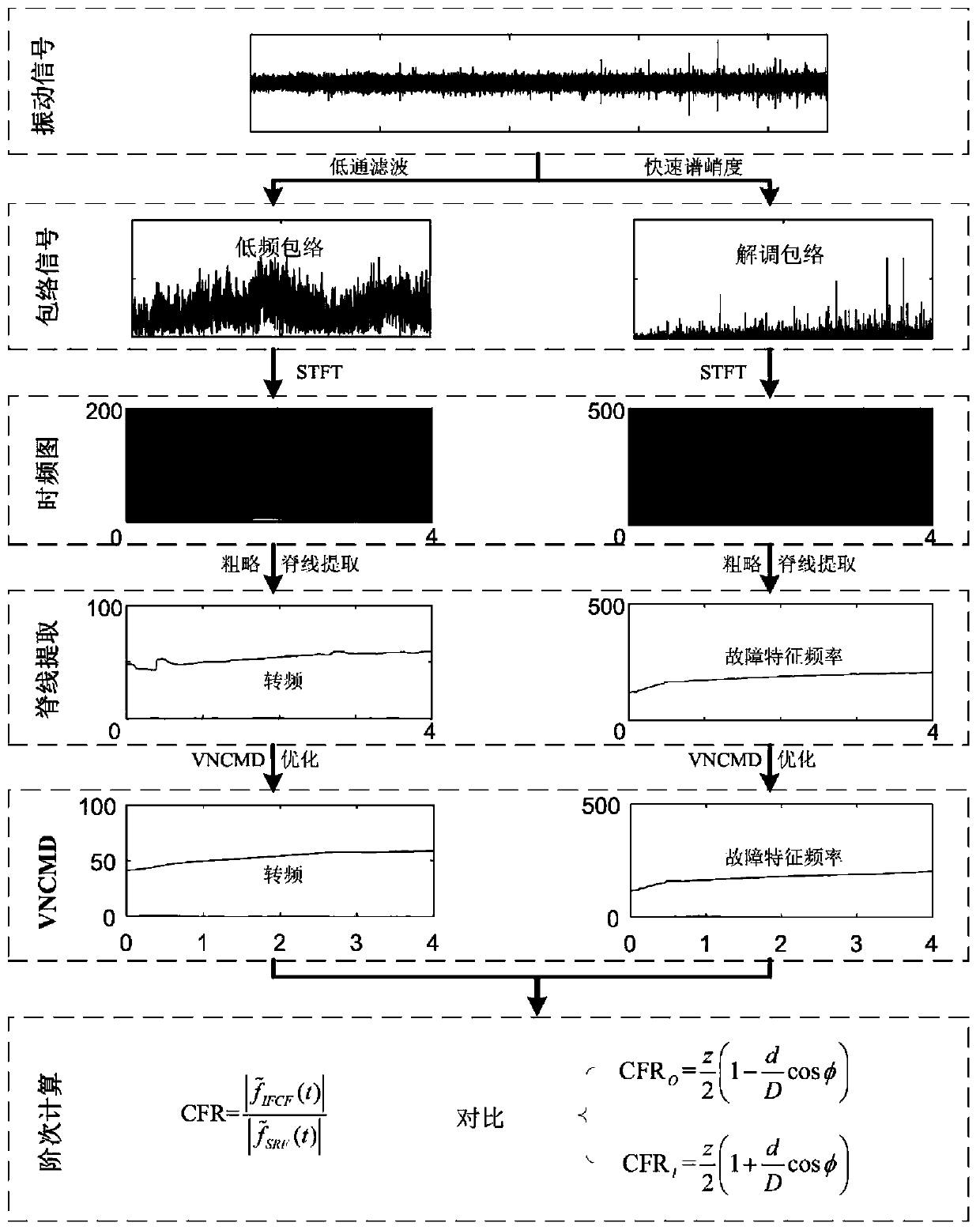

[0048] The invention provides a method for diagnosing faults of variable-speed bearings with variational nonlinear mode decomposition of feature information separation. Based on the ridge pre-extraction method, the method adopts the variational nonlinear mode decomposition method to adaptively realize the accurate estimation of the frequency ridge, which overcomes the difficulties existing in the traditional time-frequency analysis method.

[0049] The object of the present invention is achieved like this, and the present invention comprises the steps:

[0050] (1) Use the vibration signal sensor to collect the dynamic signal of the rolling bearing.

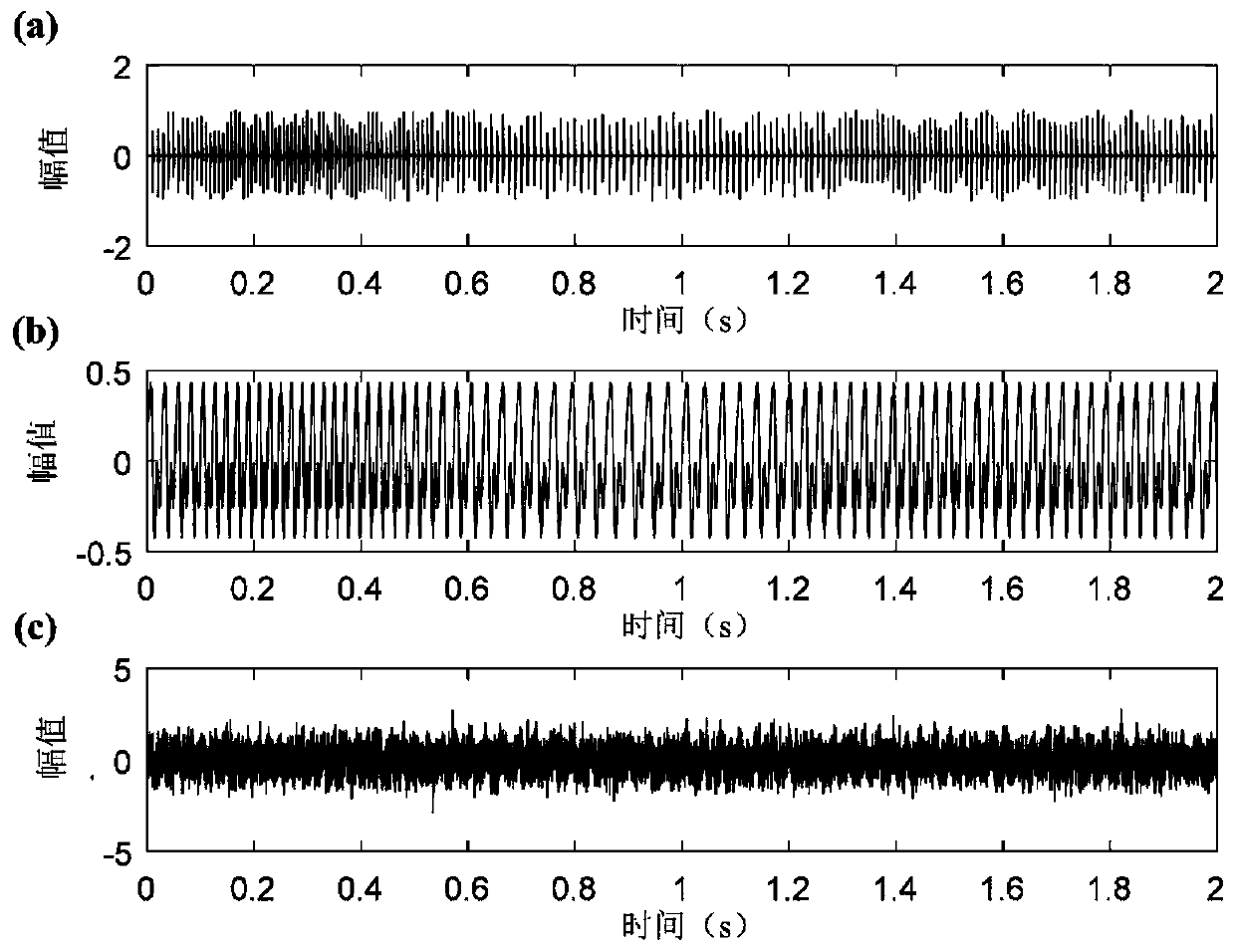

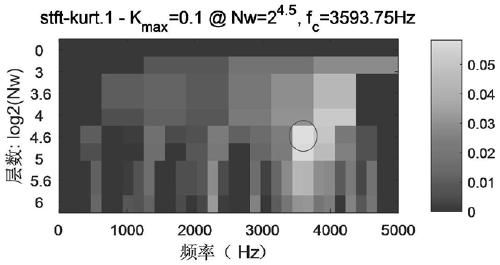

[0051] (2) Separate the low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com