Piston temperature field simulation test device and test method

A technology of simulating test and piston temperature, applied in the direction of internal combustion engine testing, etc., can solve the problems of difficult heat distribution control and short fuel replacement cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

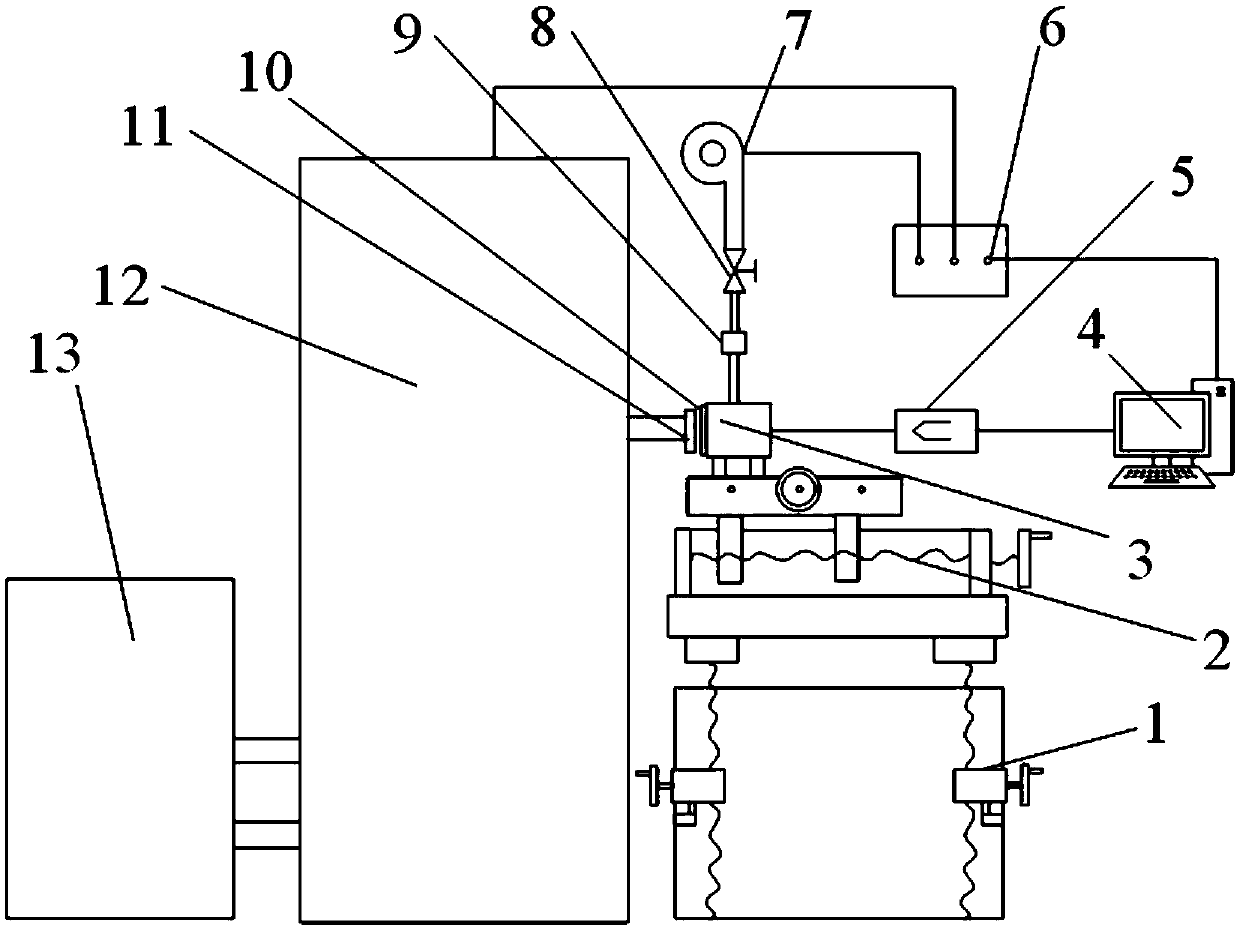

[0039] like figure 1 As shown, a piston temperature field simulation test device includes: worm gear screw lifting device 1, vertical and horizontal moving platform 2, cooling tooling 3, computer 4, thermocouple temperature acquisition instrument 5, controller 6, and a 2.2KW centrifugal blower 7. Electric air volume control valve 8, thermal anemometer 9, piston 10, induction heater 11, GP100KW high frequency induction heating equipment 12 and water cooling system 13;

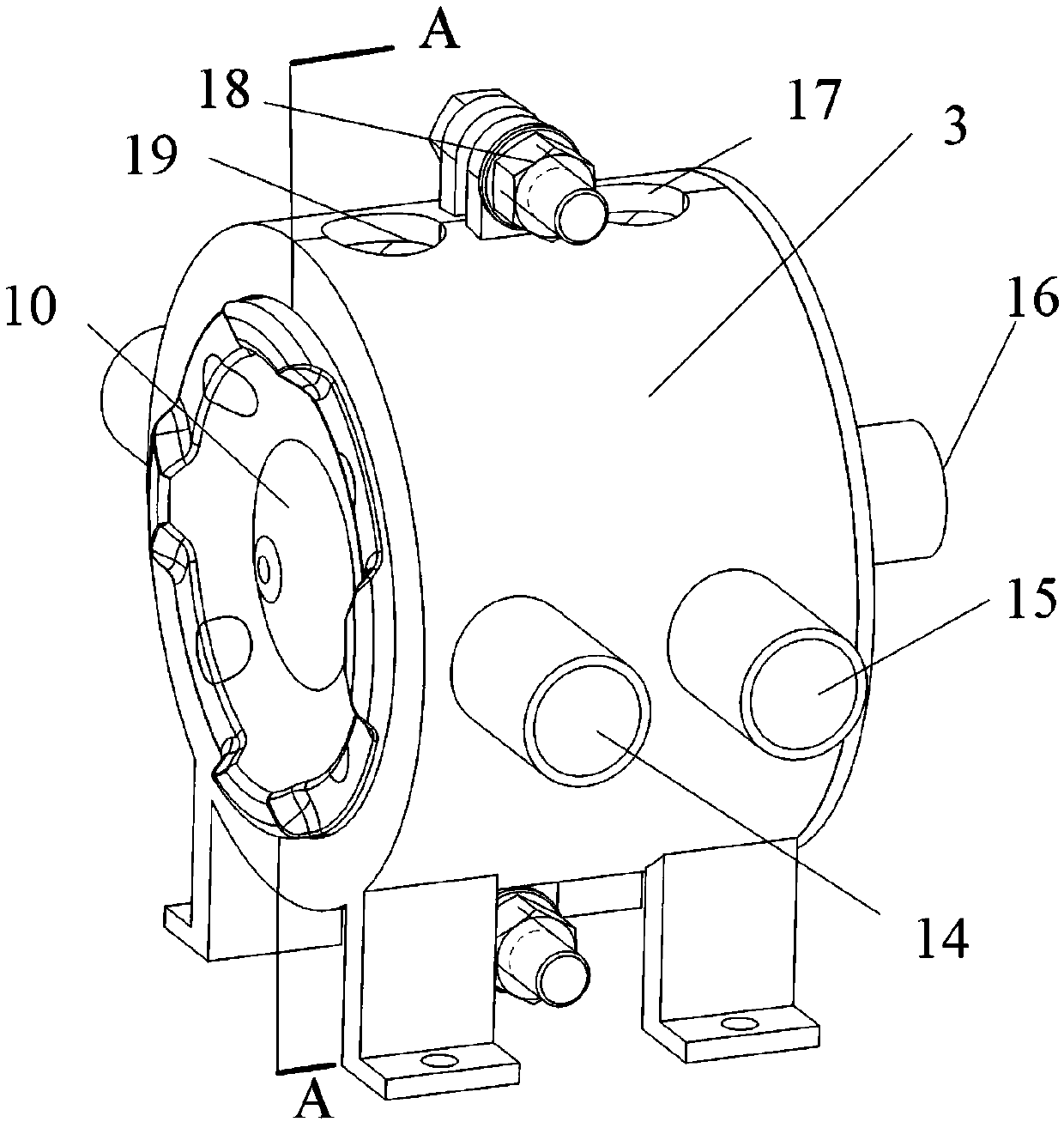

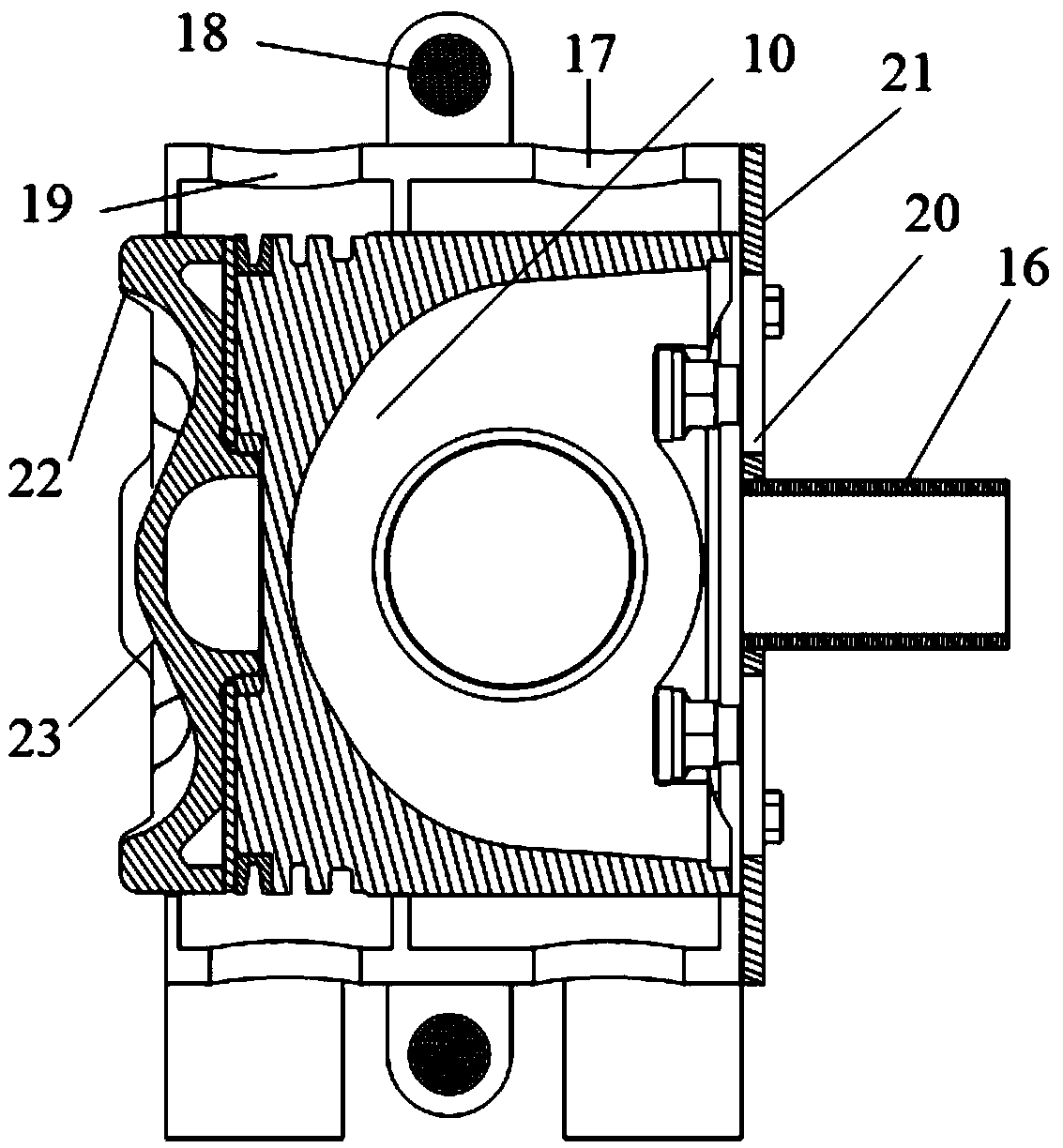

[0040] The vertical and horizontal moving platform 2 is installed on the described worm gear and screw type lifting device 1, and the cooling tool 3 is installed on the vertical and horizontal moving platform 2. The tooling 3 moves left and right; the cooling tooling 3 is used to fix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com