Icing sensor

An icing sensor and heater technology, applied in the sensor field, can solve the problems of loss of controllability, asymmetry of lift and tension, poor reliability, etc., and achieve the effects of reducing mental burden, not easy to fatigue and cracking, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

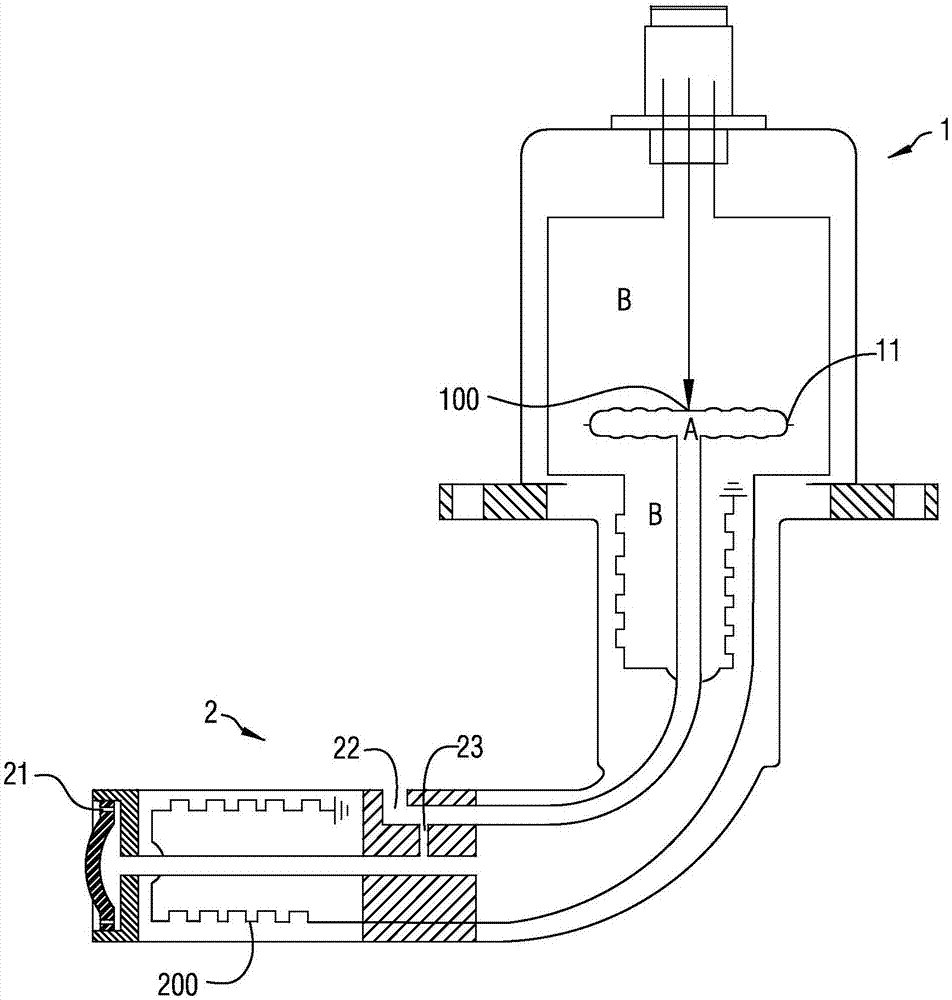

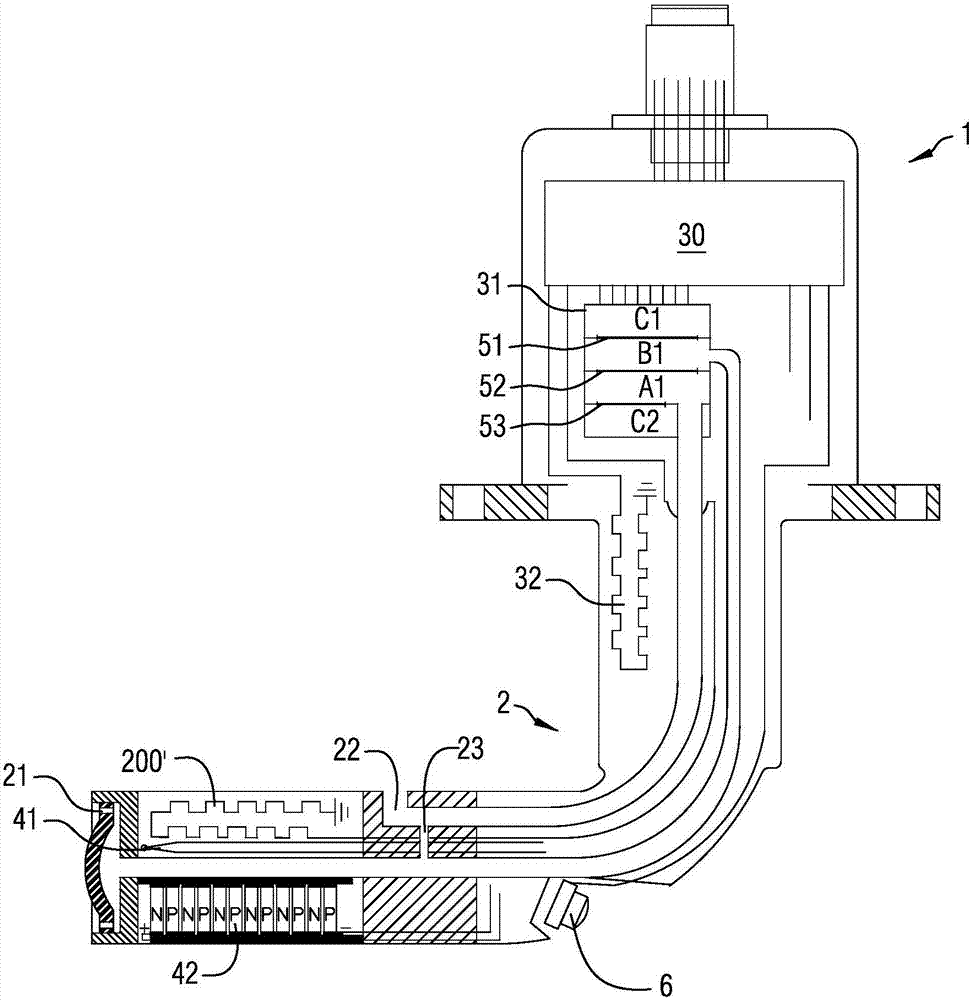

[0017] figure 2 It is a schematic diagram of the structure and principle of the icing sensor according to a specific embodiment of the present invention; see figure 2 As shown, the present invention provides a kind of icing sensor, which includes a base 1 and an elbow 2 connected to each other, and the end of the elbow 2 is provided with 20 air inlet holes 21 with a diameter of 0.7mm. The side wall of the elbow 2 is provided with 8 static pressure holes 22 with a diameter of 2.5mm. The base 1 is provided with a controller 30, a pressure chamber 31, and a tube root heater 32. The inside of the elbow 2 is provided with The thermal resistance temperature measuring elemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com