Display device and manufacturing method thereof

A technology for a display device and a manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of short service life of display devices, and achieve the effect of solving short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

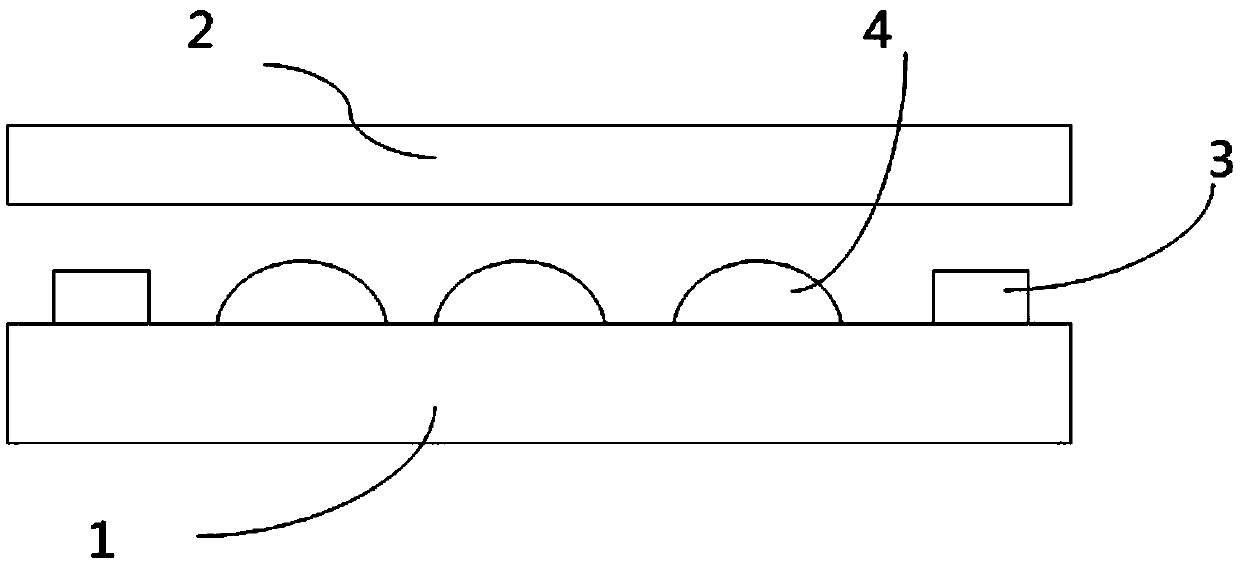

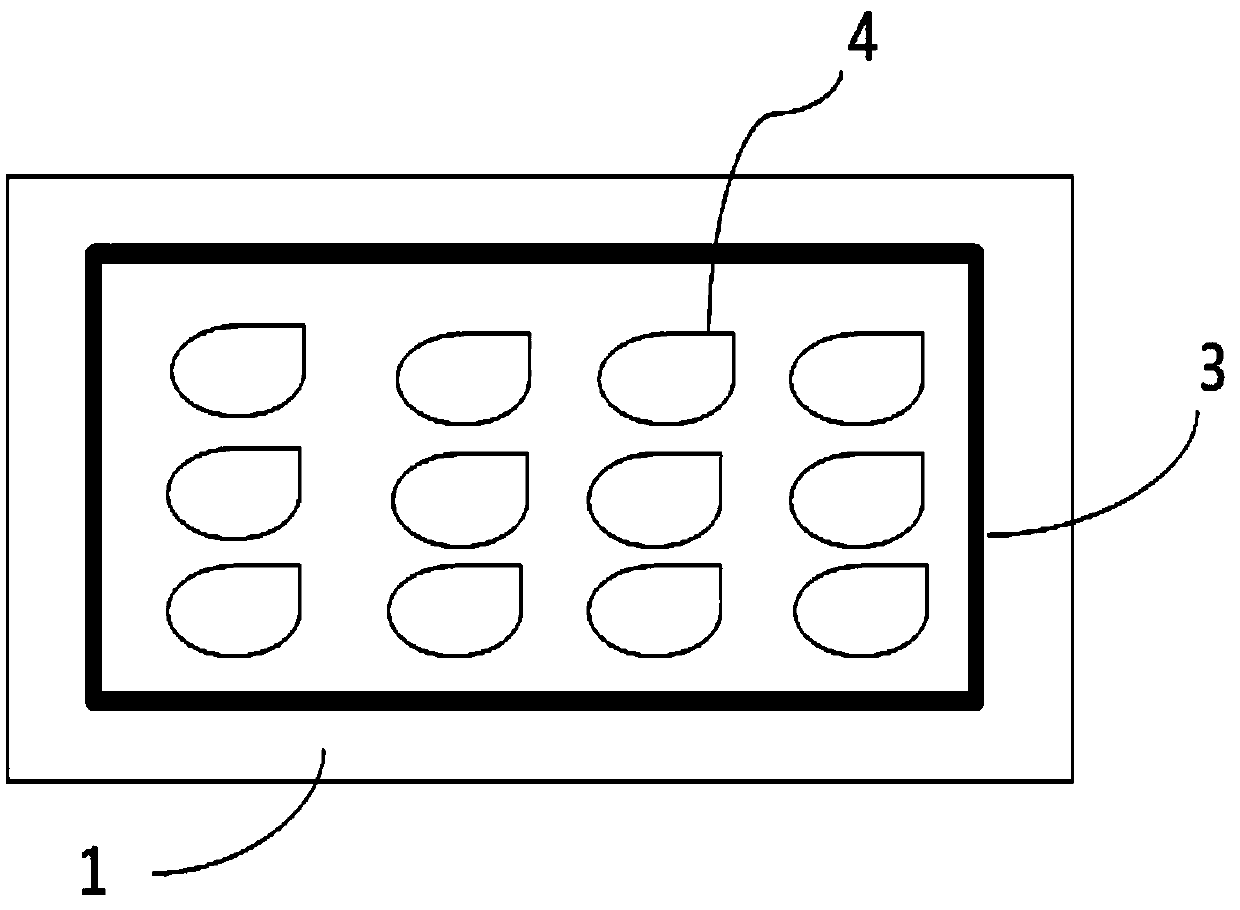

[0036] Figure 3 to Figure 5 It is a structural schematic diagram of the first embodiment of the present invention, a display device includes: a display panel 1 and a cover plate (not shown in the figure) arranged oppositely, and a liquid adhesive layer 4 arranged between the display panel 1 and the cover plate, the The display panel 1 and the cover plate are adhered by a frame glue 3 , the display panel 1 includes a display area and a non-display area surrounding the display area, and the glue frame 3 is arranged in the non-display area.

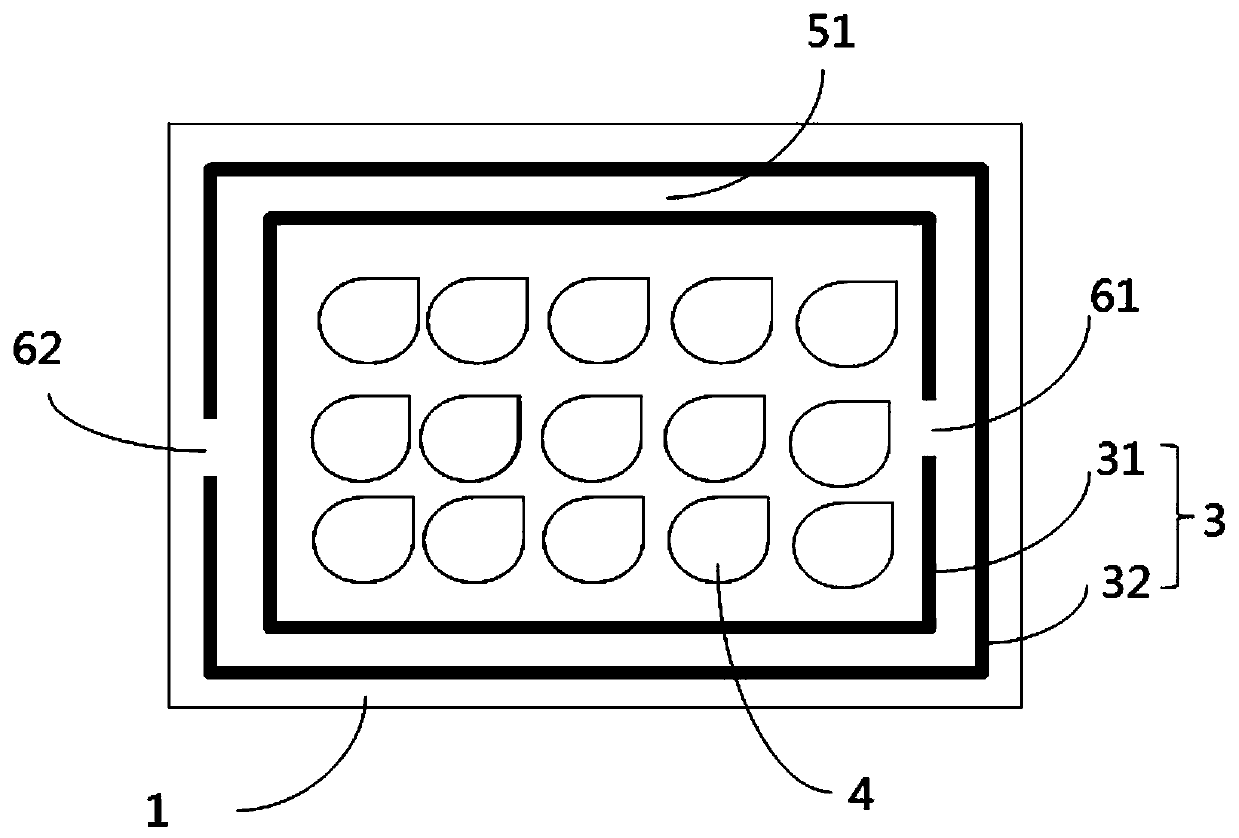

[0037] The plastic frame 3 includes a first plastic frame 31 and a second plastic frame 32, the first plastic frame 31 and the second plastic frame 32 are arranged concentrically, the second rubber frame 32 is arranged on the outside of the first rubber frame 31, and the first plastic frame A first slit 51 is formed between the frame 31 and the second rubber frame 32, a first gap 61 is provided on the first rubber frame 31, a second gap 62 ...

Embodiment 2

[0041] Figure 6 It is a structural schematic diagram of the second embodiment of the present invention, a display device includes: a display panel 1 and a cover plate (not shown in the figure) arranged oppositely, and a liquid adhesive layer 4 arranged between the display panel 1 and the cover plate, the The display panel 1 and the cover plate are adhered by a frame glue 3 , the display panel 1 includes a display area and a non-display area surrounding the display area, and the glue frame 3 is arranged in the non-display area.

[0042] The plastic frame 3 includes a first plastic frame 31 and a second plastic frame 32, the first plastic frame 31 and the second plastic frame 32 are arranged concentrically, the second rubber frame 32 is arranged on the outside of the first rubber frame 31, and the first plastic frame A first slit 51 is formed between the frame 31 and the second rubber frame 32, a first notch 61 is respectively arranged on the upper frame and the lower frame of th...

Embodiment 3

[0046] Figure 7 It is a structural schematic diagram of the third embodiment of the present invention, a display device includes: a display panel 1 and a cover plate (not shown in the figure) arranged oppositely, and a liquid adhesive layer 4 arranged between the display panel 1 and the cover plate, the The display panel 1 and the cover plate are adhered by a frame glue 3 , the display panel 1 includes a display area and a non-display area surrounding the display area, and the glue frame 3 is arranged in the non-display area.

[0047] The plastic frame 3 includes a first plastic frame 31 and a second plastic frame 32, the first plastic frame 31 and the second plastic frame 32 are arranged concentrically, the second rubber frame 32 is arranged on the outside of the first rubber frame 31, and the first plastic frame A first slit 51 is formed between the frame 31 and the second plastic frame 32 , and a first notch 61 is respectively provided on the upper frame and the lower fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com