A new process for in-situ generation of ammonia to synthesize oxime

A technology of in-situ generation and ammonia synthesis, applied in oxime preparation, organic chemistry and other directions, can solve the problems of affecting catalyst recycling, unavoidable side reactions, low utilization rate of raw material ammonia, etc., and achieve high product yield and post-processing technology. Simple, highly selective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

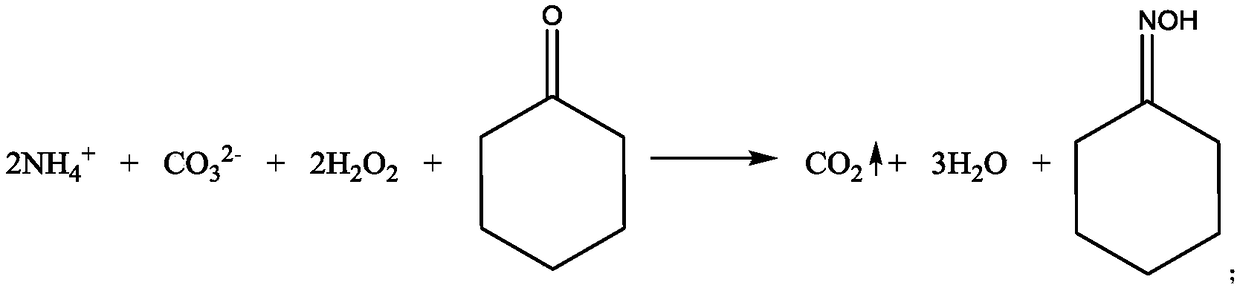

Method used

Image

Examples

Embodiment 1

[0031] Add 36g butanone (0.5mol), 535g mass concentration of 5% ammonium chloride aqueous solution (0.5mol), 2% catalyst TS-1 into the flask, start the stirrer, adjust to a suitable stirring rate. The temperature gradually rose to 60°C, and at the same time, 145.75g of 20% sodium carbonate (0.275mol) aqueous solution and 27.3% of hydrogen peroxide 65.4g (0.525mol) were added dropwise, and the dropwise addition time was 3h; after the dropwise addition, the reaction was continued for 2h, and the reaction ended After cooling to room temperature, the catalyst was filtered out, and 43.4 g of butanone oxime was obtained by gas chromatography analysis with a yield of 99.7%.

Embodiment 2~3

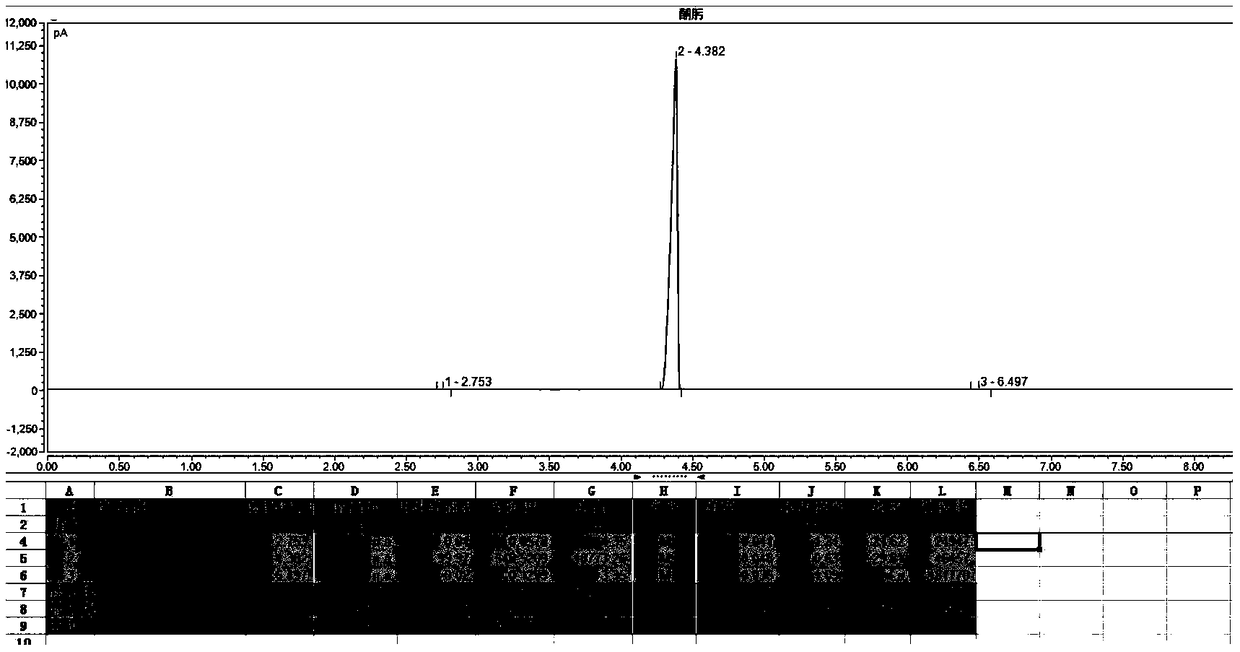

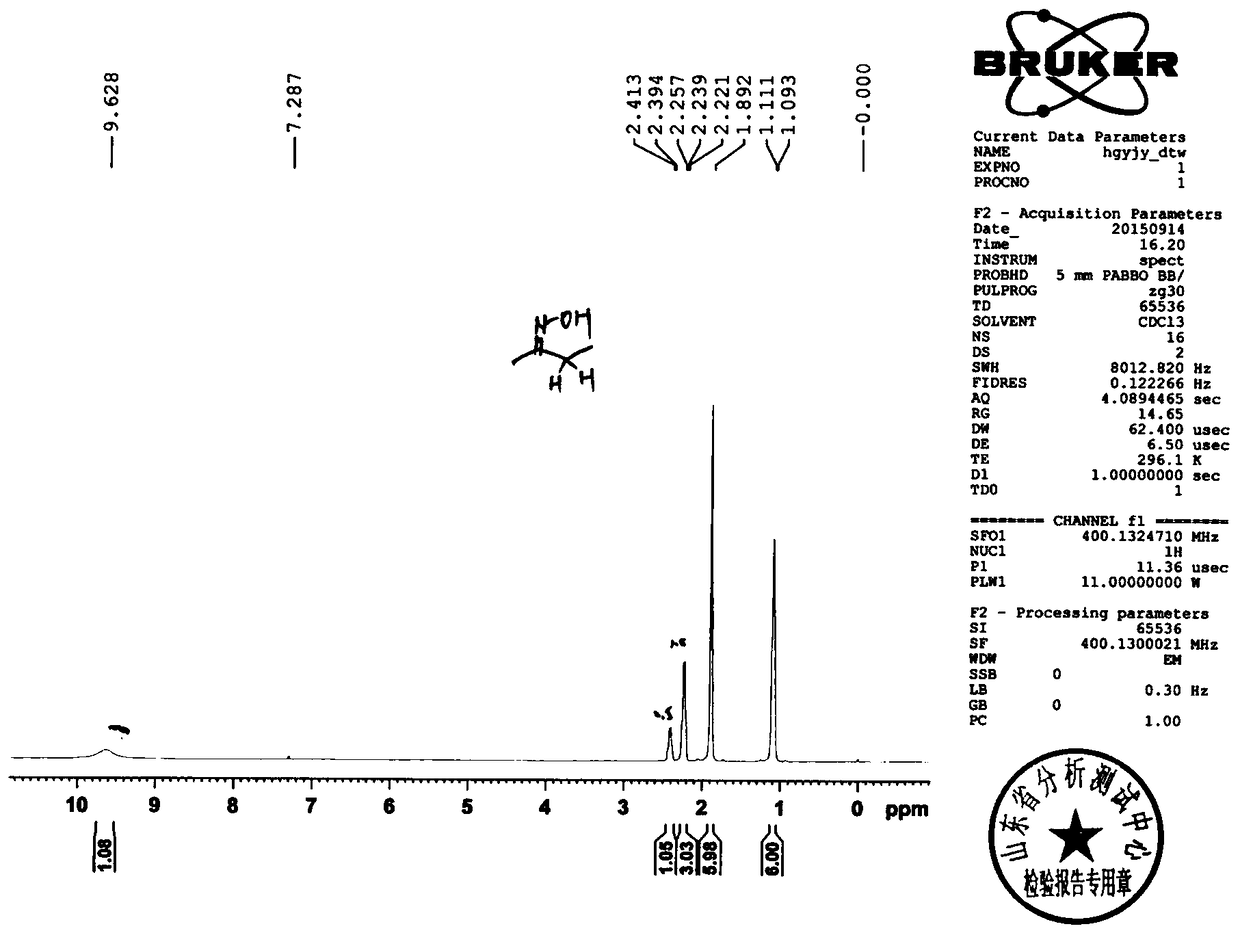

[0033] Butanone is replaced by acetone or cyclohexanone, and all the other are with embodiment 1. The yields of the products acetone oxime and cyclohexanone were determined by gas phase to be 99.6% and 99.9% respectively.

Embodiment 4~8

[0035] The operating steps and operating conditions for synthesizing butanone oxime in Example 1 are the same, except that the strong base and weak acid salt and the ammonium salt are different. Determined by gas phase analysis, the yield of butanone oxime is shown in Table 1.

[0036] The butanone oxime yield of table 1. embodiment 4~8

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com