Wheel hub cutter management system and method

A tool management and hub technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve problems such as cumbersome installation and maintenance, save processing procedures, monitor tool life in real time, and prepare tools in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

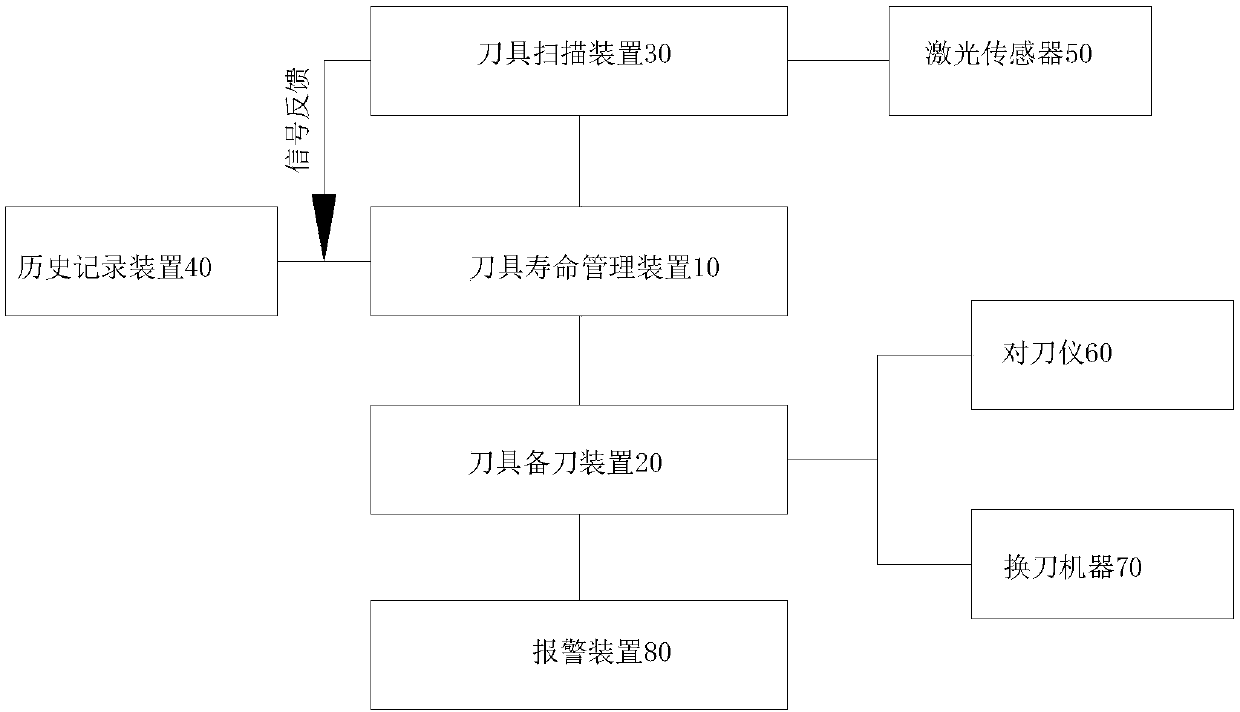

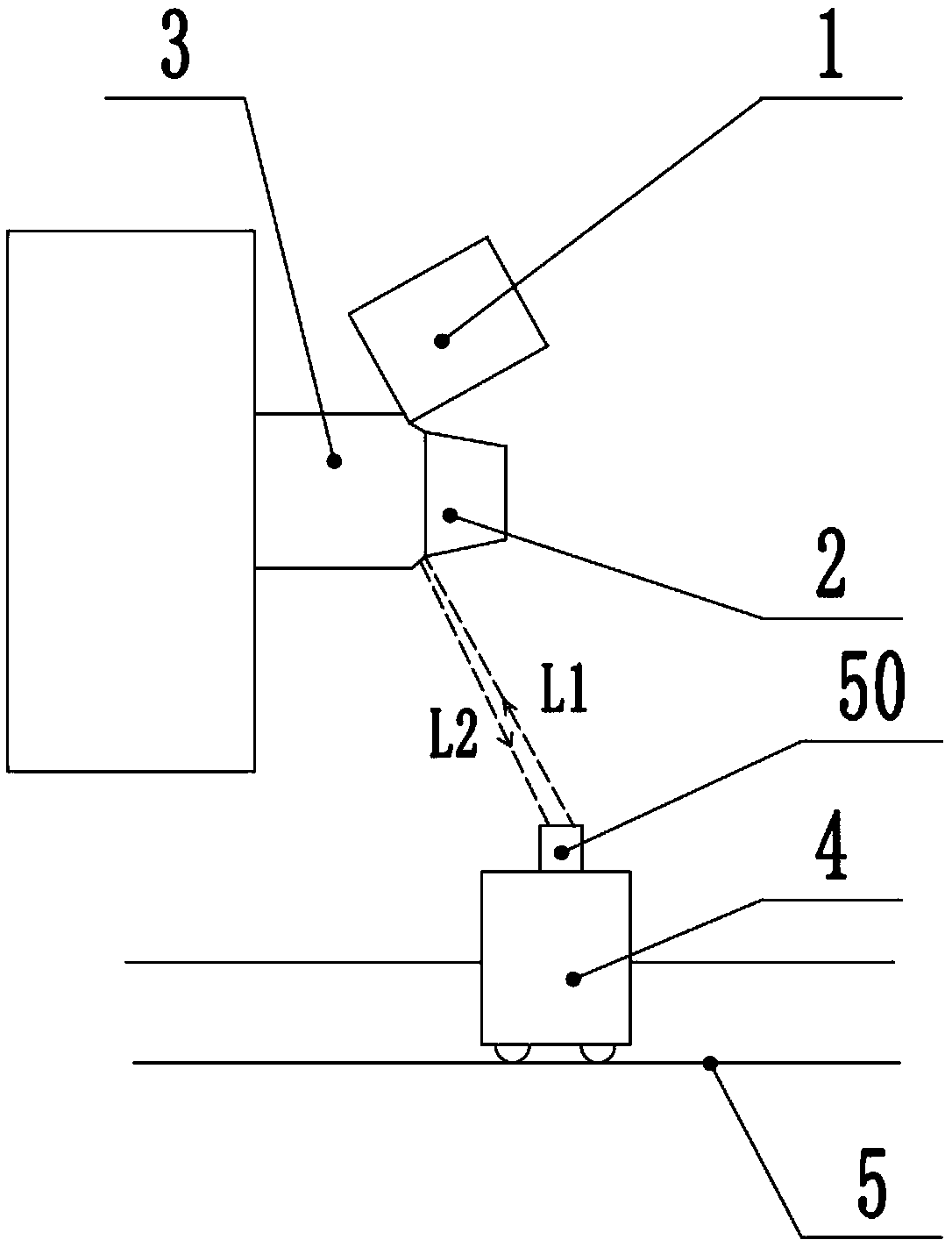

[0034] A hub tool management system provided by the present invention includes a tool life management device 10, and the tools respectively connected to the tool life management device 10 have a tool device 20 and a scanning device installed on the ground rail robot 4;

[0035] The scanning device is used to scan the processing size of the processed hub during the process of the robot clamping the hub, and then feed back the scanning signal to the tool life management device 10; the scanning device includes a laser sensor, and the laser sensor includes a laser, a laser Detector and measuring circuit, the laser emitted by the laser is detected by the laser detector through the surface variable reflection; the tip of the tool is worn during processing, and when the degree of wear reaches the limit value, the processing size becomes larger, and this change will be detected by the laser sensor detected, the laser sensor receives the signal and sends the detection result to the tool...

Embodiment 2

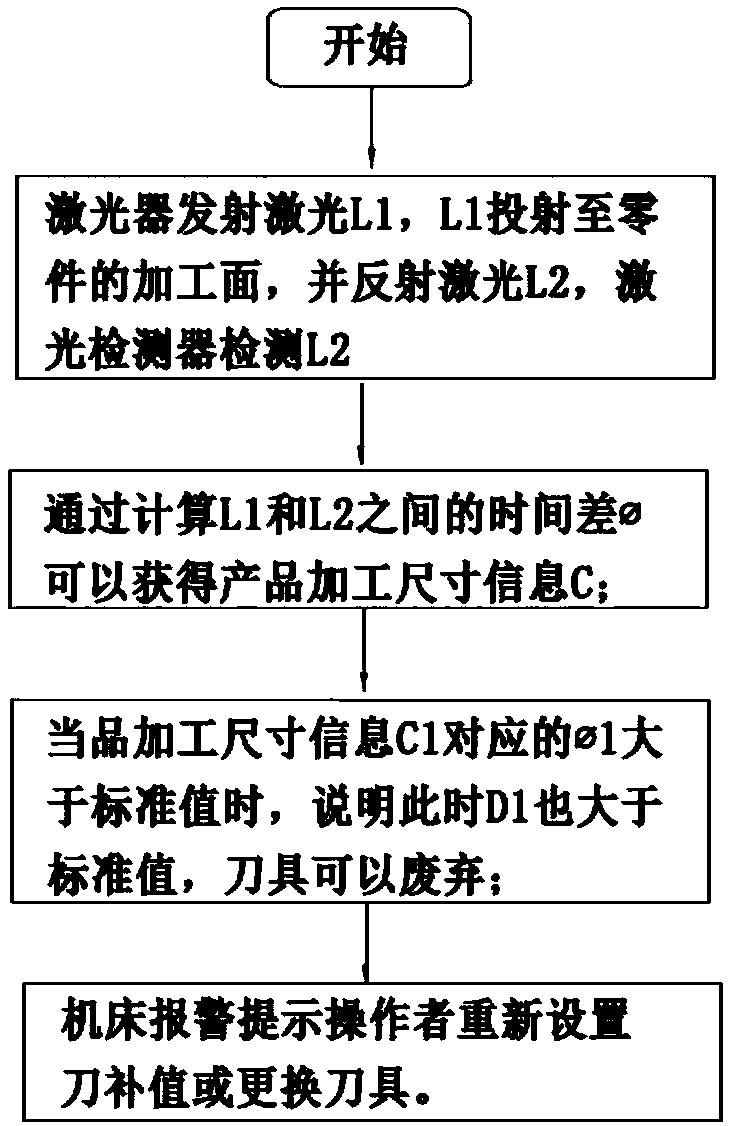

[0040] The present invention provides a hub tool management method, the method includes the following steps:

[0041] When the use state of the tool is a normal working state, judge whether the remaining life of the tool is less than or equal to a preset life according to the scanning detection information and past experience life information;

[0042] When the remaining life of the tool is less than or equal to the preset life, it is determined that tool preparation is required; when the remaining life of the tool is greater than the preset life, it is determined that tool preparation is not required;

[0043]When the wheel hub is processed in the production line, the ground rail robot 4 is installed on the guide rail, and the scanning device installed on the ground rail robot 4 gripper will scan the wheel hub processing size before the robot clamps the wheel hub from the processing machine tool; when the actual processing size becomes larger , but does not exceed the machini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com