A construction method of head car shrink model based on force and stiffness equivalent and head car shrink model

A head car and stiffness technology, which is applied in the field of head car reduction, can solve problems such as difficult to accurately simulate, change the center of gravity of the train, and cannot guarantee the similar stiffness of the car body, and achieve the effect of satisfying structural similarity and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present invention will be further described below in conjunction with examples.

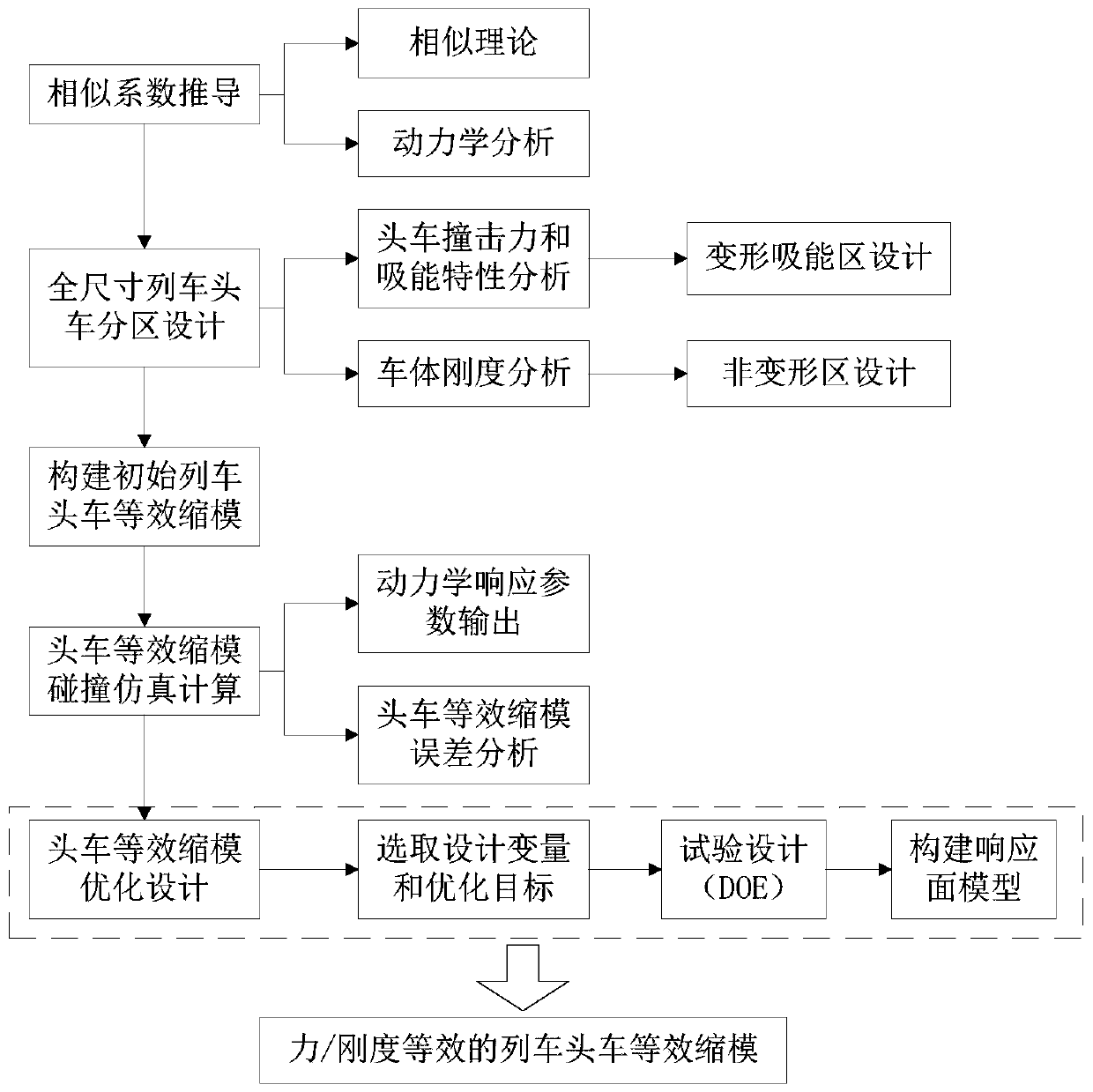

[0088] Such as figure 1 As shown, a kind of locomotive shrinkage model construction method based on force and stiffness equivalent provided by the present invention mainly includes the following four aspects:

[0089] 1. Similarity factor derivation of kinetic parameters;

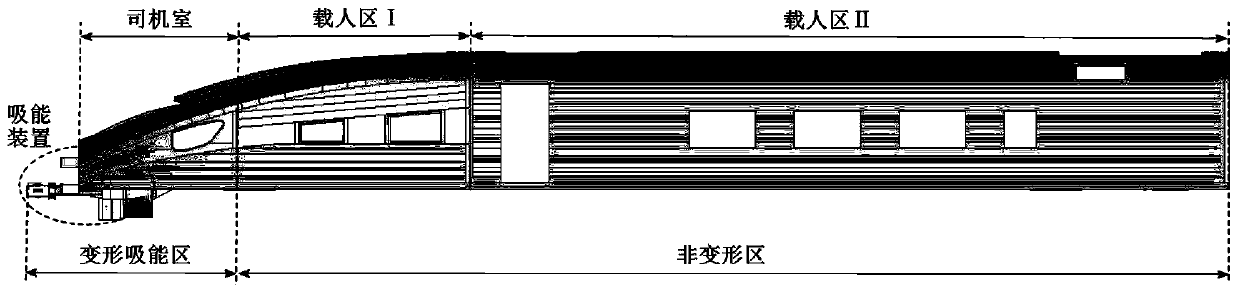

[0090] 2. Partition design of the first car;

[0091] 3. Build the initial reduced model of the head car;

[0092] 4. The collision simulation calculation of the shrinking mold of the head car and the optimization of the shrinking mold of the head car.

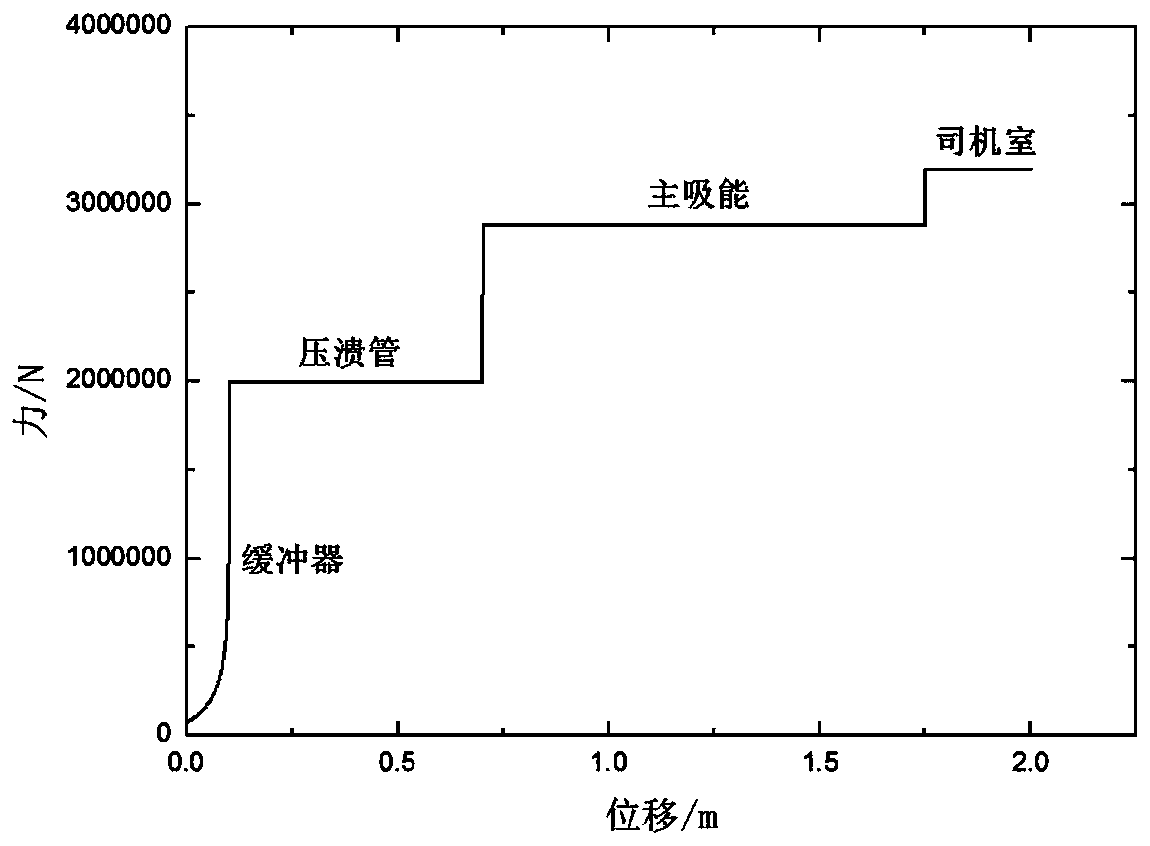

[0093] 1. The similarity factor derivation about the dynamic parameters: the present invention considers that the train is a thin-walled aluminum alloy structure, so the similarity relationship of its dynamic characteristics is analyzed for the thin-walled plate shell, that is, the dynamic balance equation based on the thin-walled plate shell adopts similarity T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com