Micro light-emitting element and display device

A technology for light-emitting components and display devices, which is applied to electrical components, semiconductor devices, electric solid-state devices, etc., can solve the problems of reducing the alignment accuracy of light-emitting diode chips and external circuits, and not having enough alignment margin, and achieves large alignment. Bit margin, the effect of improving alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

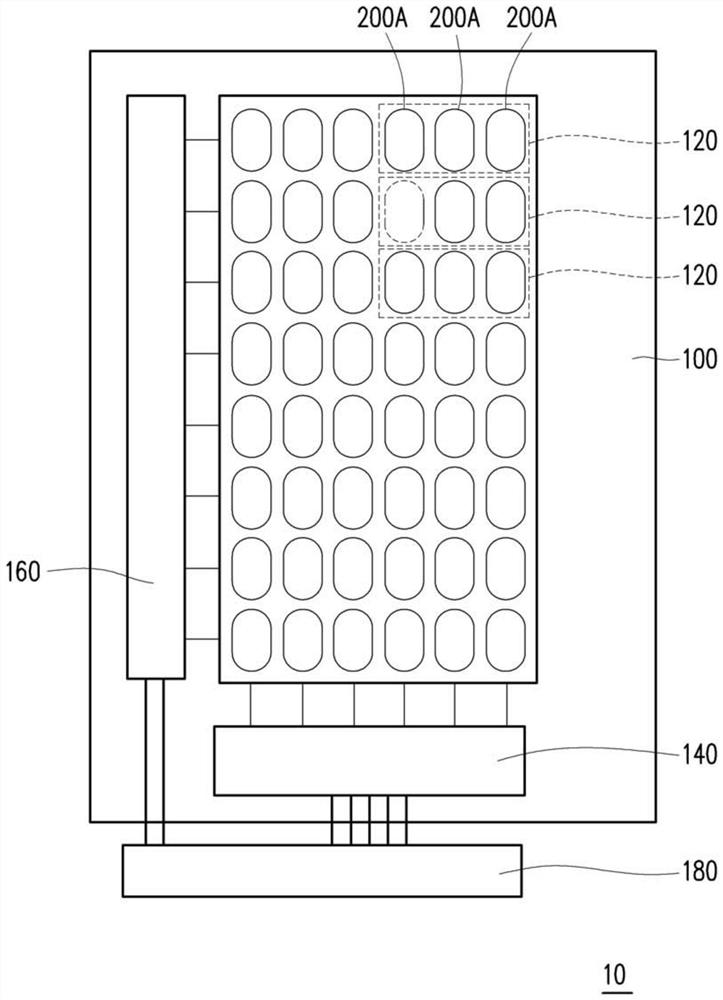

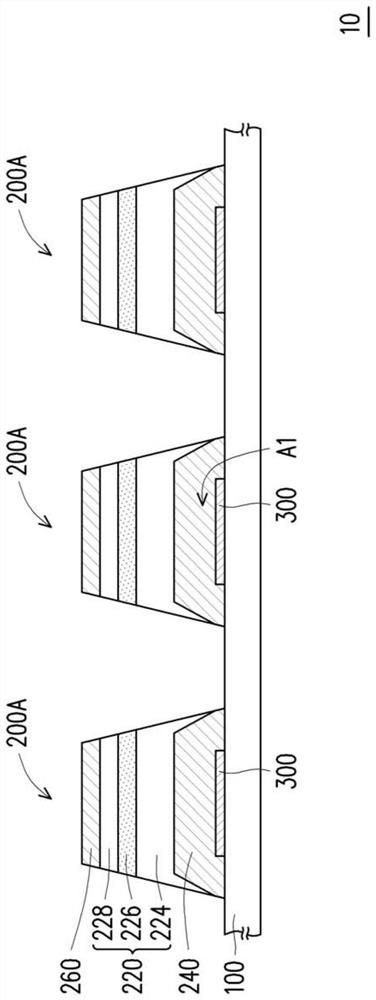

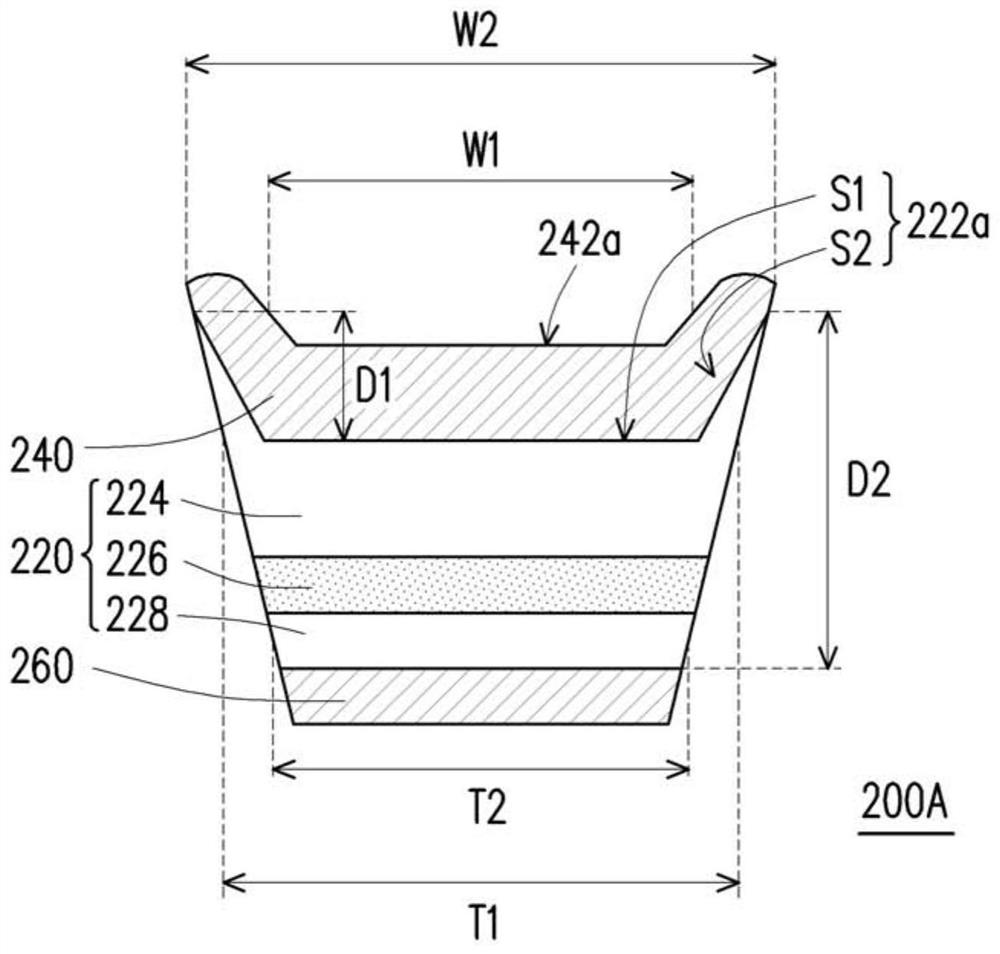

[0060] Figure 1A A schematic top view of a display device according to an embodiment of the present invention is shown. Figure 1B shown as Figure 1A A partial cross-sectional schematic diagram of the display device. Figure 1C A schematic diagram of a micro light-emitting element as an embodiment of the present invention is shown. Please also see Figure 1A , Figure 1B and Figure 1C, the display device 10 of this embodiment includes a driving substrate 100 , a plurality of micro light emitting elements 200A and a plurality of bonding pads 300 . The micro-light emitting elements 200A and the bonding pads 300 are dispersedly disposed on the driving substrate 100 , and the micro-light-emitting elements 200A correspond to the bonding pads 300 respectively. Each micro-light emitting device 200A includes an epitaxial structure layer 220 , a first-type electrode 240 and a second-type electrode 260 . The epitaxial structure layer 220 has a first receiving groove 222a. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com