Electric automobile starting-stopping device shell stamping die and technology

A technology for electric vehicles and stamping dies, which is applied in the field of stamping production of auto parts, can solve problems such as uneven thickness, prone to cracking, and difficult stretching, so as to achieve improved dimensional accuracy, high dimensional accuracy, and avoid pressure that is not easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

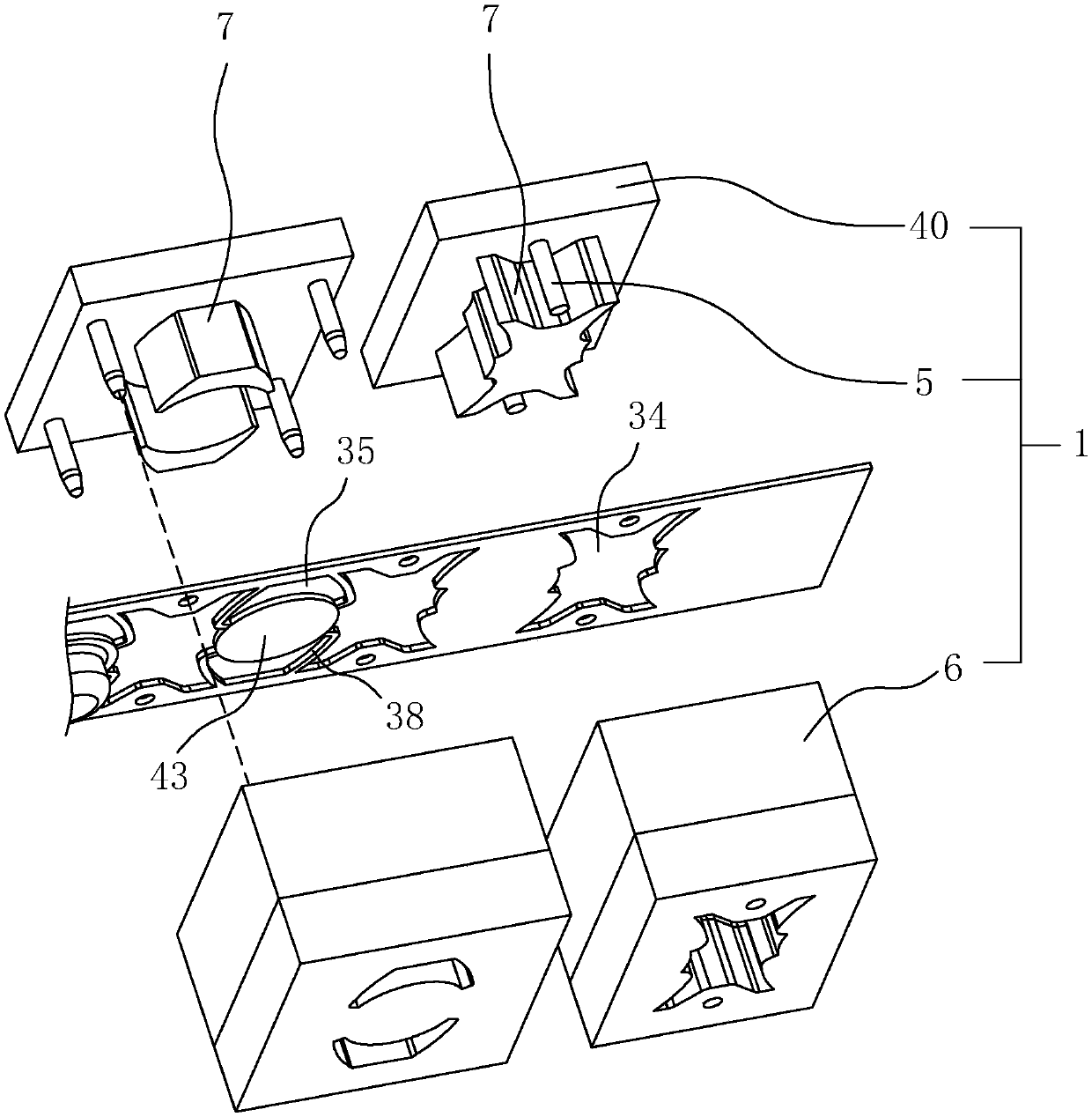

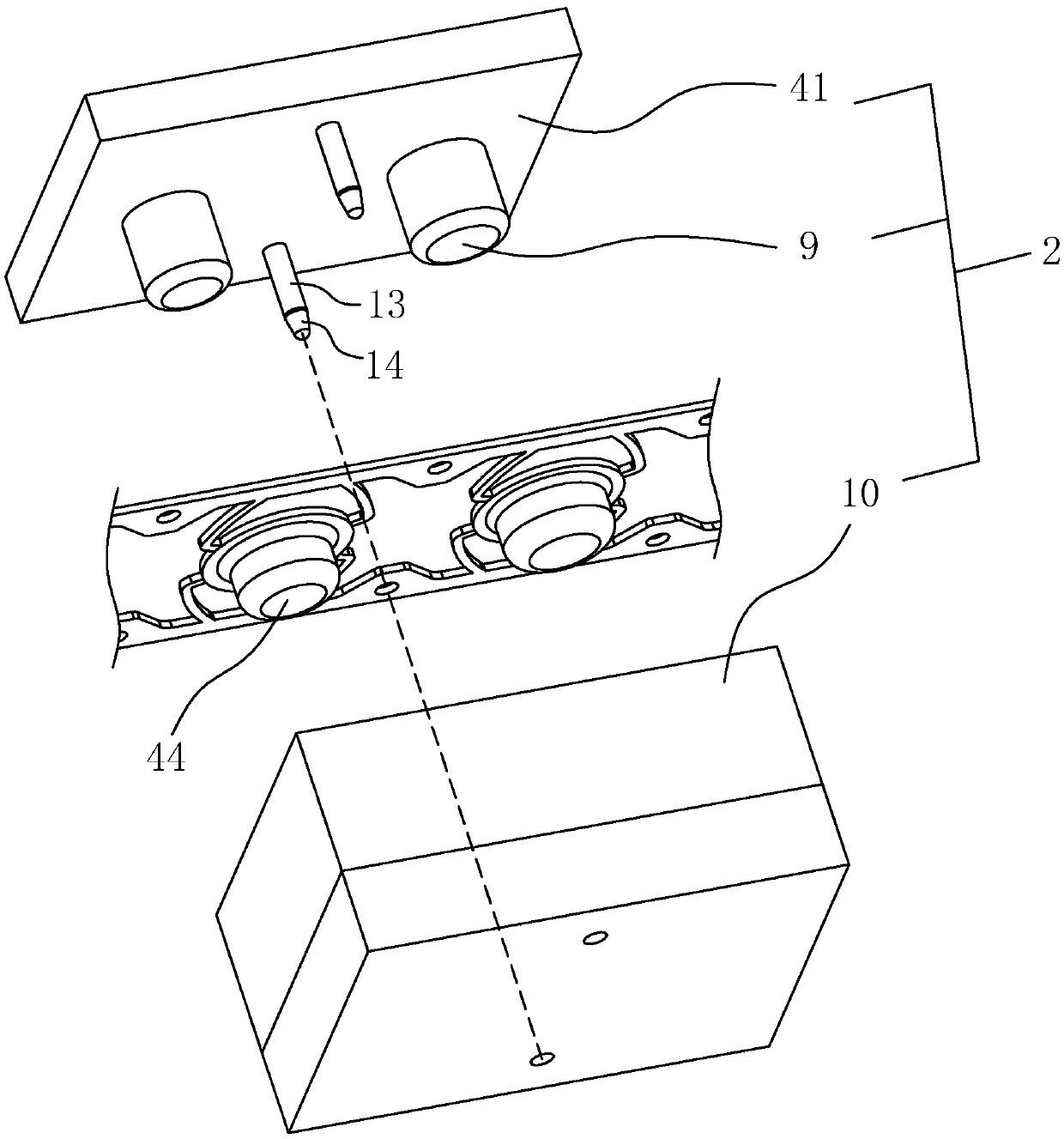

[0048] refer to figure 1 , a stamping mold for the start-stop device shell of an electric vehicle, comprising an upper mold base 59 and a lower mold base 60, the upper mold base 59 is fixedly connected with the punch part of the punching machine, and the lower mold base 60 is fixedly connected with the working platform of the punching machine; It also includes a preprocessing mold 1 for preprocessing the strip, a stretching mold 2 for stretching the gap between the process parts, a shrinking die 3 for shrinking and stamping the process parts, and a trimming process part transition The shaping mold 21 with a relatively circular arc, the rotary cutting mold 31 for rotary cutting the process parts, and the blanking mold 4 for final blanking. The preprocessing mold 1, stretching mold 2, necking mold 3, shaping mold 21, rotary cutting mold 31 and blanking mold 4 are arranged in sequence along the length direction of the strip.

[0049] refer to figure 1 and figure 2 , the pre...

Embodiment 2

[0058] refer to figure 1 , a shell stamping process for an electric vehicle start-stop device, comprising the following steps:

[0059] Before stamping, first install the material strip on the feeding turntable, the material strip is made of 1.6mm cold-rolled steel plate; the stamping machine is fixed with a liquid storage bottle for storing stamping oil, and the liquid storage bottle is provided with a drip tube, a drip tube Input the stamping oil to the material belt, so that the punching machine can better stamp the material belt;

[0060] Step 1, first feed the strip into the mold cavity; when stamping starts, the upper mold and the lower mold of the mold are separated, and the strip is inserted from the mold cavity formed between the upper mold and the lower mold;

[0061] refer to figure 2 , step 2, then punch out the positioning holes, and the positioning holes are equidistantly arranged along the length direction of the material strip; the punching punch 5 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com