Economical automatic tooth welding machine

A gear welding machine and an economical technology, which is applied in the field of gear welding machines, can solve the problems that the welding work of the alloy cutter head cannot be satisfied, and the automatic gear welding machine cannot provide welding wires and welding pieces at the same time, so as to achieve convenient and fast loading and unloading of pieces. , Simple structure, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

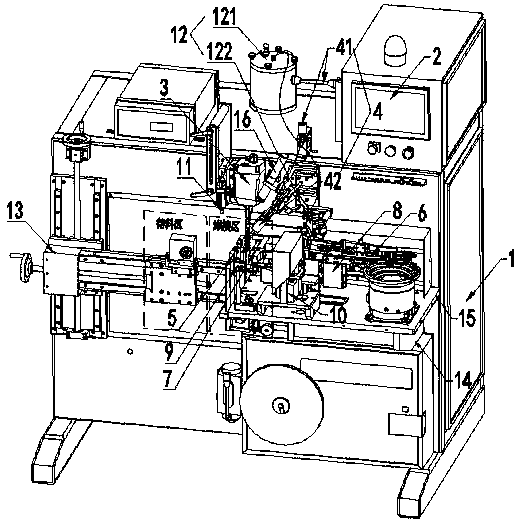

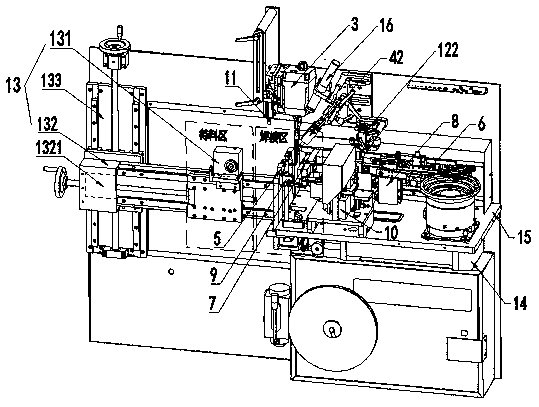

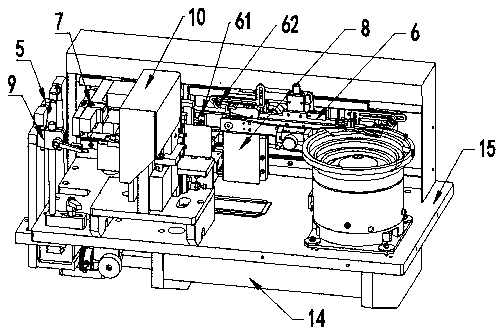

[0025] Depend on figure 1 , figure 2 , image 3It is known that an economical automatic gear welding machine includes a chassis 1, the chassis 1 is provided with a touch screen 2, and an electrical control system is provided in the chassis 1, and the electrical control system is connected to the touch screen 2; the chassis 1 There are also welding mechanism 3 connected to the electrical control system, welding wire feeding mechanism 4, saw blade clamping mechanism 5, knife grain screening and conveying mechanism 6, knife grain support mechanism 7, knife grain clamping mechanism 8, saw blade tooth position Position the photoelectric switch 9, the solder sheet conveying mechanism 10, the saw blade tooth pressing mechanism 11, the solder glue adding mechanism 12 and the saw blade disk mechanism 13; 122, the glue storage tank 121 provides solder glue to the glue adding assembly 122 through the pipeline; the welding wire feeding mechanism 4 is composed of the welding wire source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com