A pressure release mechanism and a vacuum adsorption and dust collection device with the pressure release mechanism

A technology of pressure relief and vacuum pipelines, applied in the direction of manufacturing tools, maintenance and safety accessories, metal processing machinery parts, etc., to achieve the effect of high-efficiency long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

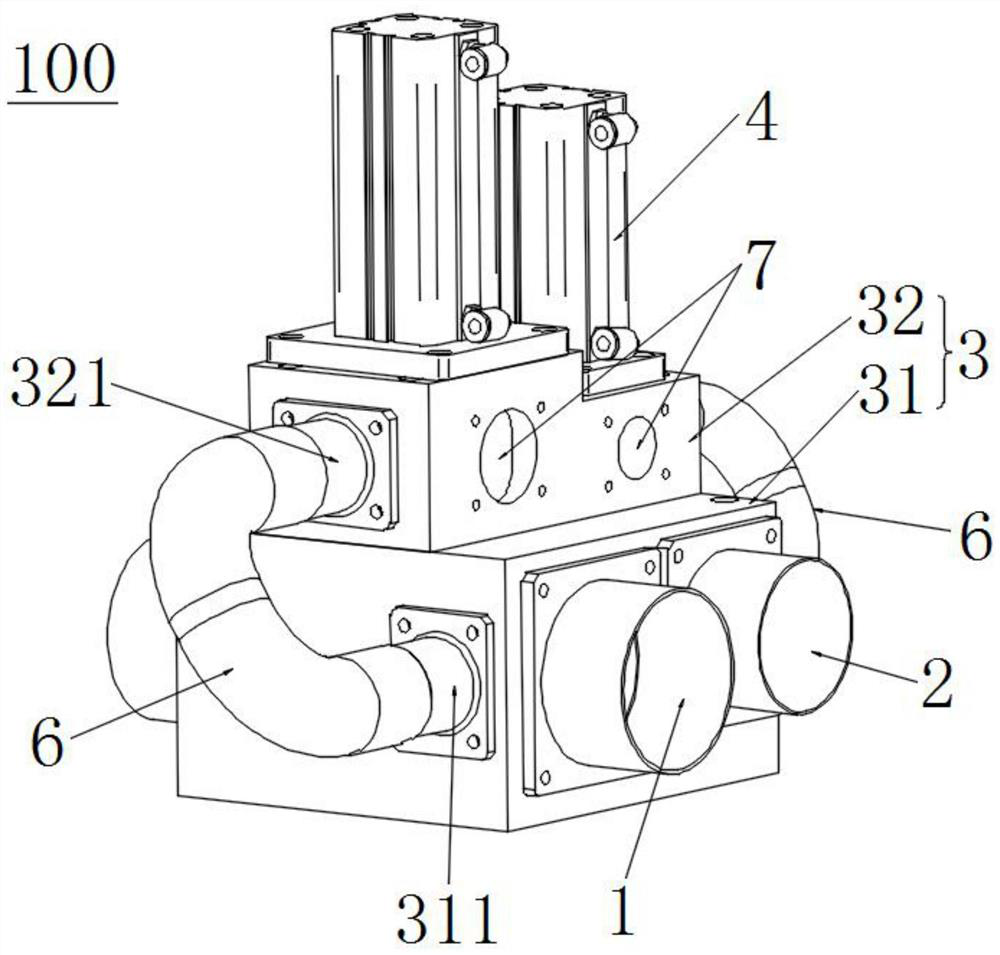

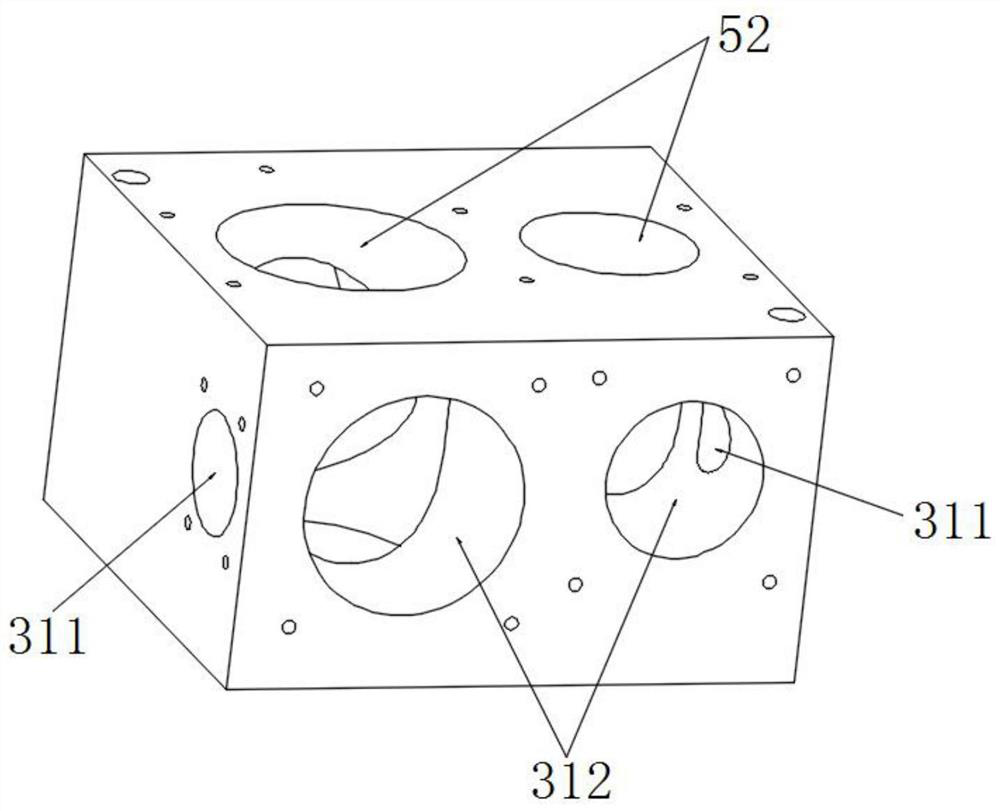

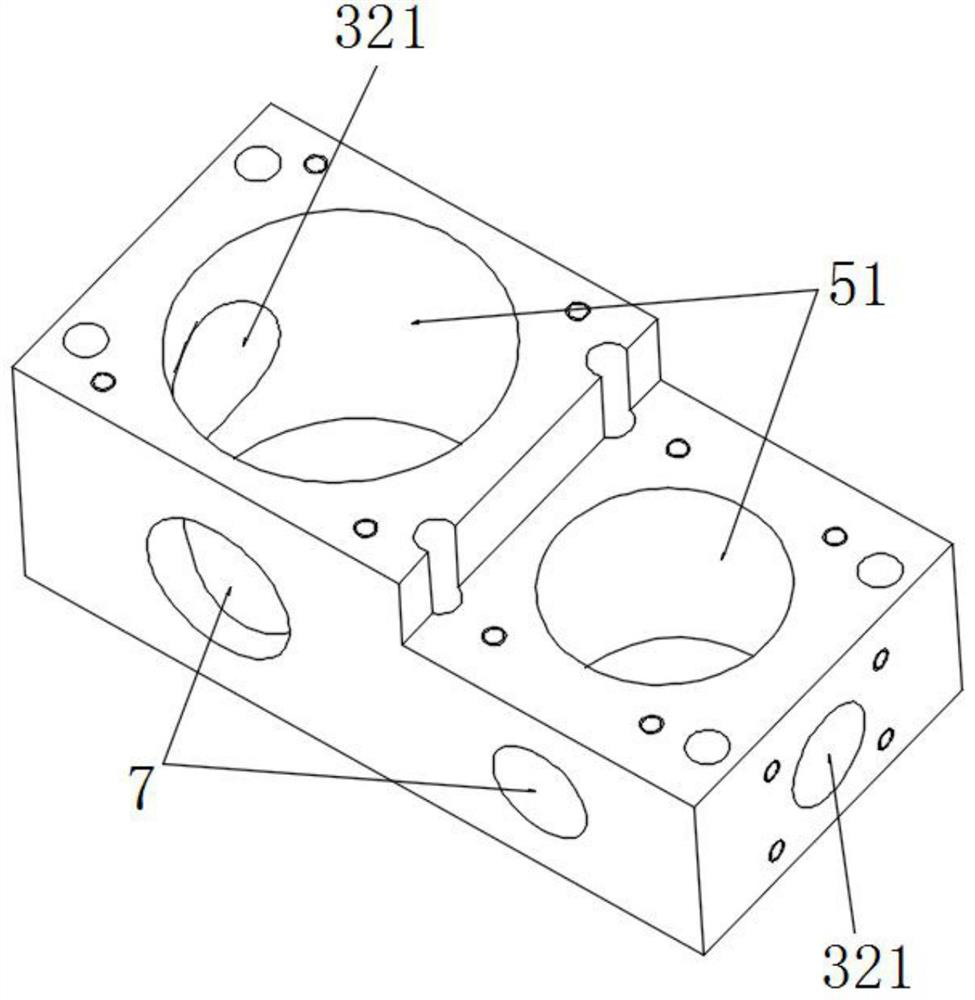

[0027] Such as figure 1 As shown, the pressure relief mechanism 100 in this embodiment includes: a vacuum pipeline 1, a dust suction pipeline 2, and an air distribution block 3. Gas mechanism 4 is located on the gas distribution block 3 and is used to export the negative pressure in the vacuum pipe and the dust suction pipe 6. The gas distribution block 3 is longitudinally provided with a gas distribution mechanism channel, and the vacuum pipe 1 and the dust suction pipe 2 traverse through the channel of the air distribution mechanism and pass through the air distribution block 3. The air distribution block 3 is provided with a pressure relief inlet 7 for allowing air to enter the channel of the air distribution mechanism. By setting the pressure relief pipe 6 for leading out the negative pressure in the vacuum pipeline 1 and the dust suction pipeline 2 and the pressure relief air inlet 7 for allowing air to enter the passage of the air distribution mechanism on the air distri...

Embodiment 2

[0038] Such as Figure 8 As shown, the vacuum adsorption and dust collection device described in this embodiment includes a pressure relief mechanism 100 as described in Embodiment 1, and a high-pressure blower 8; the high-pressure blower 8 has a high-pressure blower suction pipe 9, and the high-pressure blower One end of the suction pipe is connected with the high-pressure blower 8 , and the other end is connected with the pressure relief mechanism 100 . Further, the suction pipe of the high-pressure fan communicates with the pressure relief mechanism 100 through the vacuum pipe 1 and the dust suction pipe 2 .

[0039] Further, when the laser processing equipment is in the non-processing state, the blocking member 41 divides the blocking area of the vacuum pipeline 1 and the dust suction pipeline 2 into two parts. The first vacuum pipeline 11 connected with 9 and the second vacuum pipeline 12 arranged oppositely, the dust suction pipeline 2 includes the first dust suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com