Moving rod and moving ball assembling device and use method thereof

A technology of assembly device and movable ball, applied in assembly machine, metal processing, metal processing equipment and other directions, can solve the problems of reducing automation utilization rate, increasing processing cost, large labor cost, etc., and achieving ingenious design, high degree of automation and high precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Embodiments of the present invention will be described in detail below.

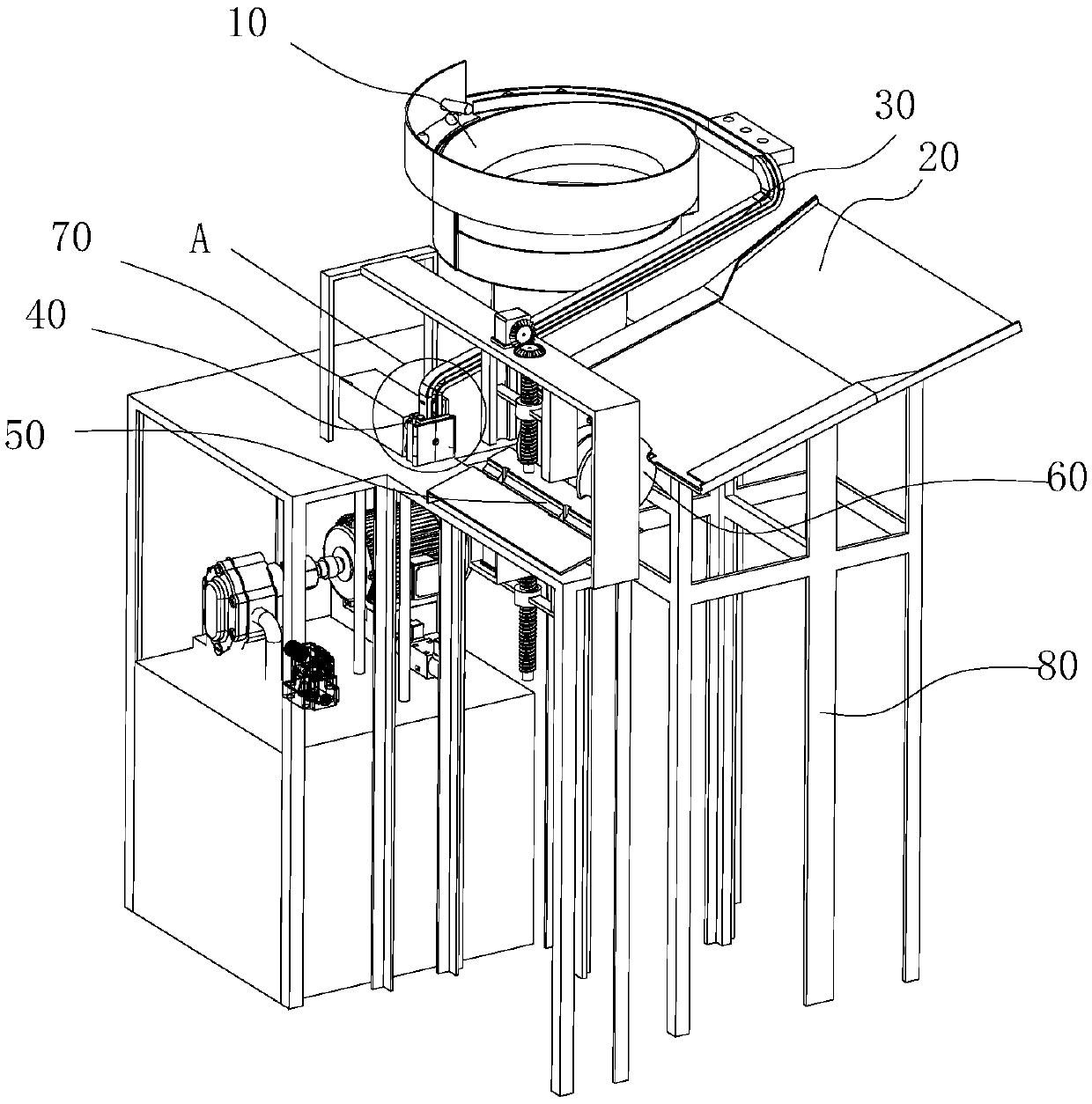

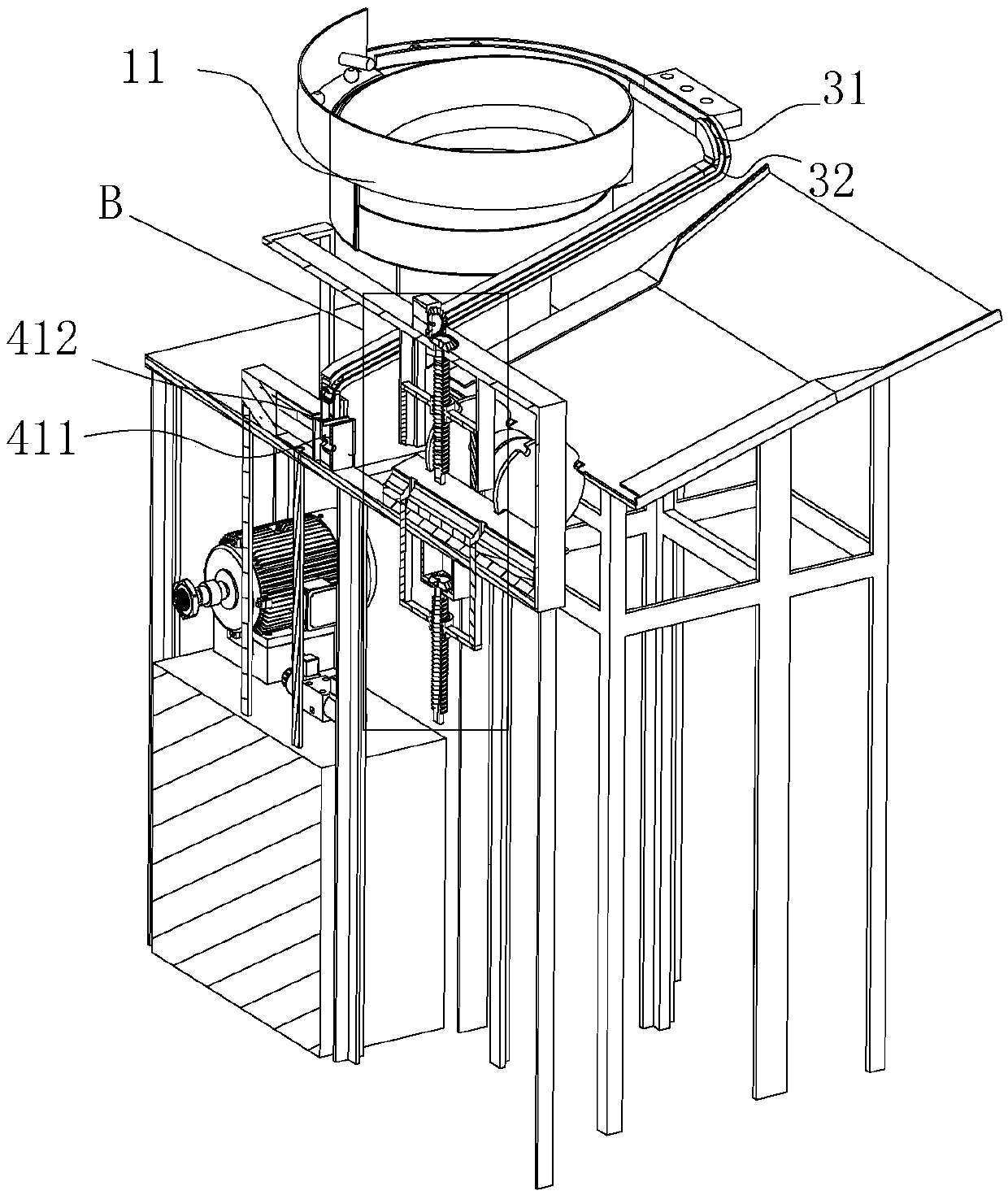

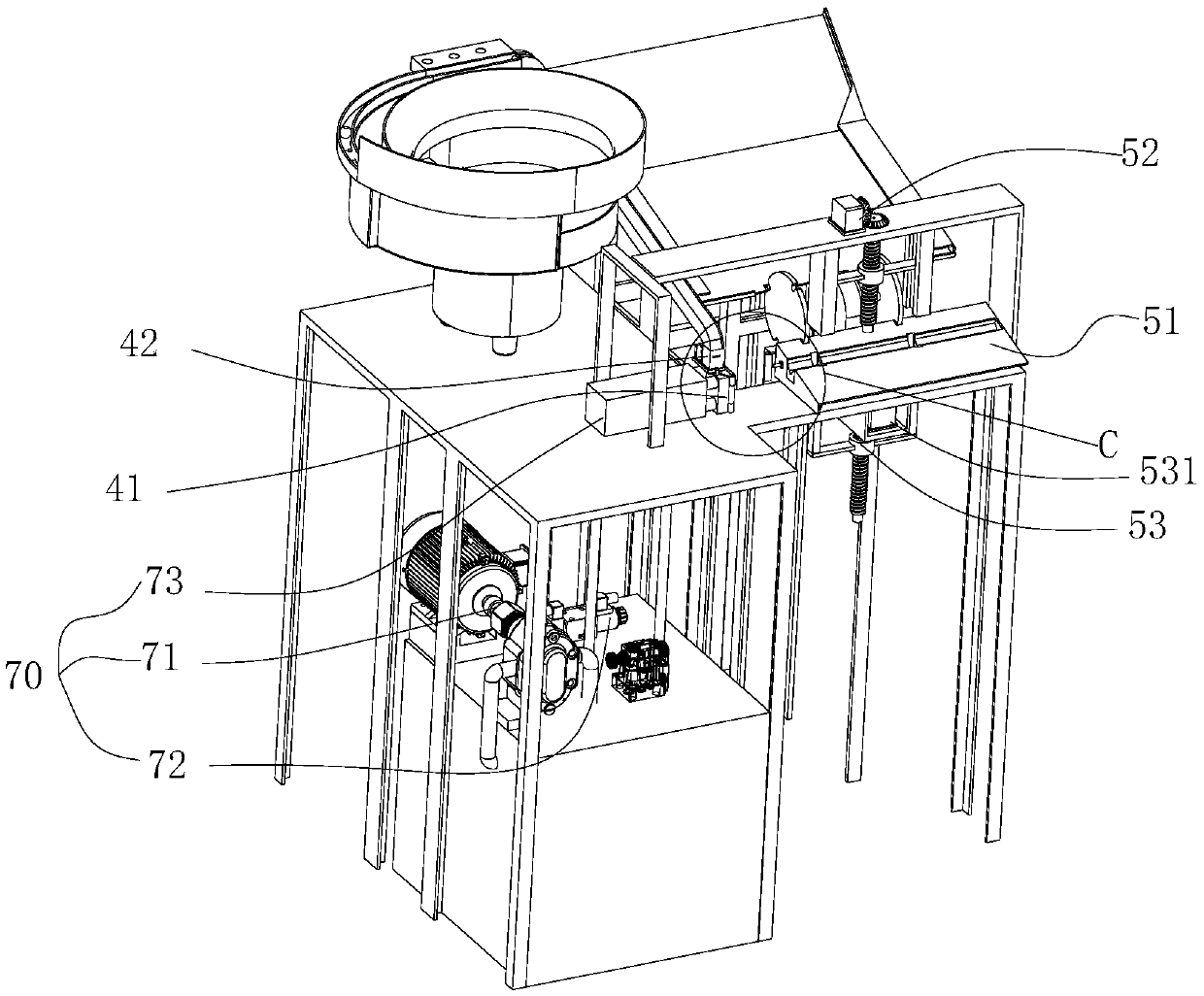

[0054] Such as Figure 1 to Figure 3 As shown, the movable rod 91 and the movable ball 92 assembly device include the first feeding mechanism 10, the second feeding mechanism 20, the material transfer track 30, the first assembling mechanism 40, and the second assembling mechanism 50; The output end of the material mechanism 10 communicates with the input end of the material transfer track 30, the output end of the material transfer track 30 communicates with the feed port 412 of the first assembly mechanism 40, and the second feed mechanism 20 The output end corresponds to the feed port 412 of the second assembly mechanism 50; the first assembly mechanism 40 is provided with a first part position 411, and the second assembly mechanism 50 is provided with a second part position 511 and a fixing mechanism, the first part position 411 corresponds to the second part position 511, at least one of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com